Method for forming variable-strength hot stamping parts by ultrahigh-strength steel

An ultra-high-strength steel and hot stamping technology, applied in the field of hot stamping, can solve problems such as inability to form variable-strength hot stamping parts, and achieve the effect of simplifying mold design and forming process, and improving accuracy and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

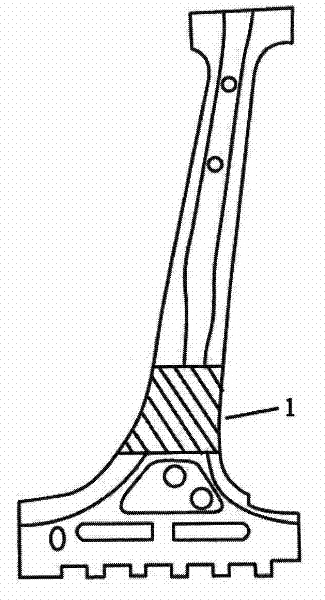

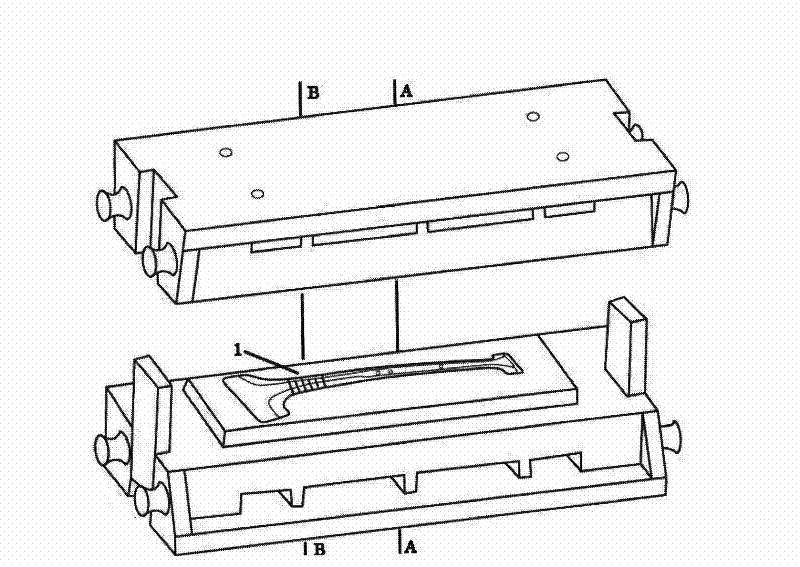

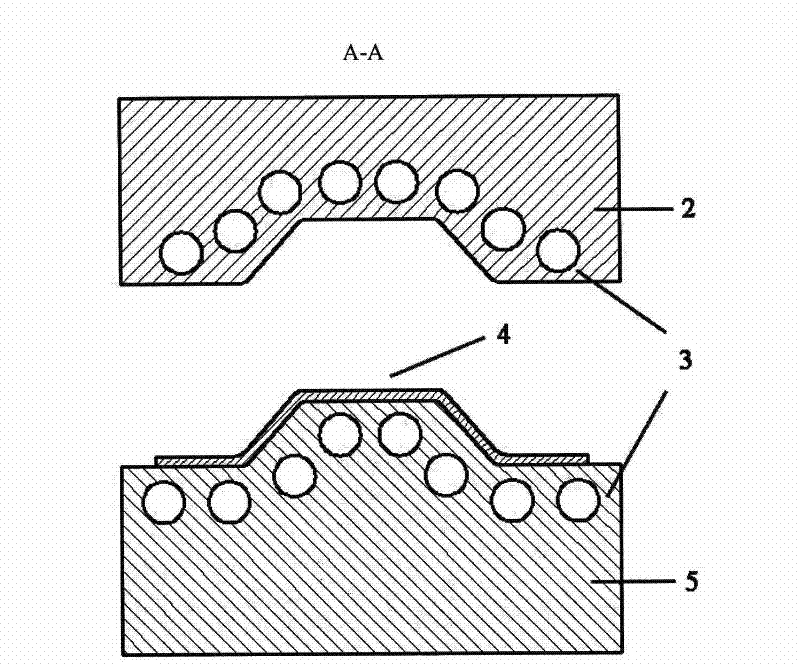

[0010] The following takes the B-pillar parts of the car as an example, combined with the attached Figure 1-4 Specific embodiments of the present invention will be described.

[0011] The convex and concave dies used for forming and cooling the sheet adopt a segmented structure, and each module has an independent cooling system with water inlet and outlet respectively. The segmented structure not only facilitates the processing of cooling pipes and improves cooling efficiency, but also can individually design cooling pipes inside the corresponding convex and concave mold modules according to the strength requirements of different positions of the parts.

[0012] The softened part of the B-pillar is located at a certain distance close to the lower fixed part, such as figure 1 shown. The softening part requires lower strength and higher plasticity, and it can be deformed first when the vehicle body collides, absorbing a large amount of energy. The softening part of the B-pil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com