Cast welding mould of storage batteries

A technology for casting and welding molds and batteries, which is applied in the field of casting and welding molds, can solve the problems of low production efficiency, prolonged battery production cycle, and low welding quality, and achieve the goals of shortening the production cycle, eliminating the pole connection process, and reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

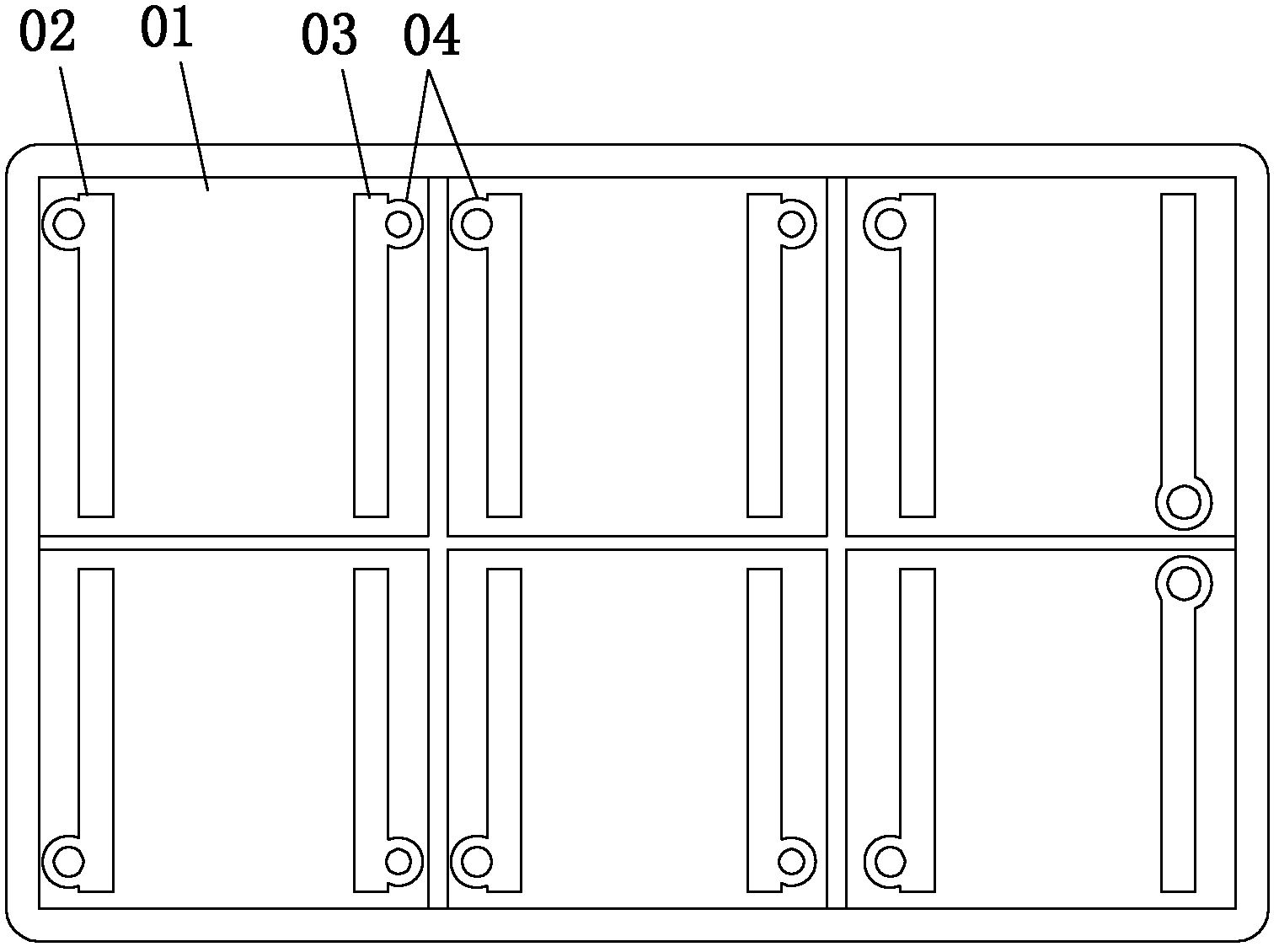

[0013] Reference figure 1 , The existing new lead-acid battery products: the battery box contains six battery cells 01, each battery cell 01 is made up of several positive and negative plates interlaced, after welding by casting and welding mold, each battery cell The positive plate tabs on the body 01 are connected to form a positive current collector 02, the negative plate tabs are connected to form a negative current collector 03, and a pole 04 is formed at one end of the positive current collector 02 and the negative current collector 03. In the series connection between two adjacent battery cells 01, the increase of this process causes the battery production cycle to be lengthened and the production efficiency is reduced.

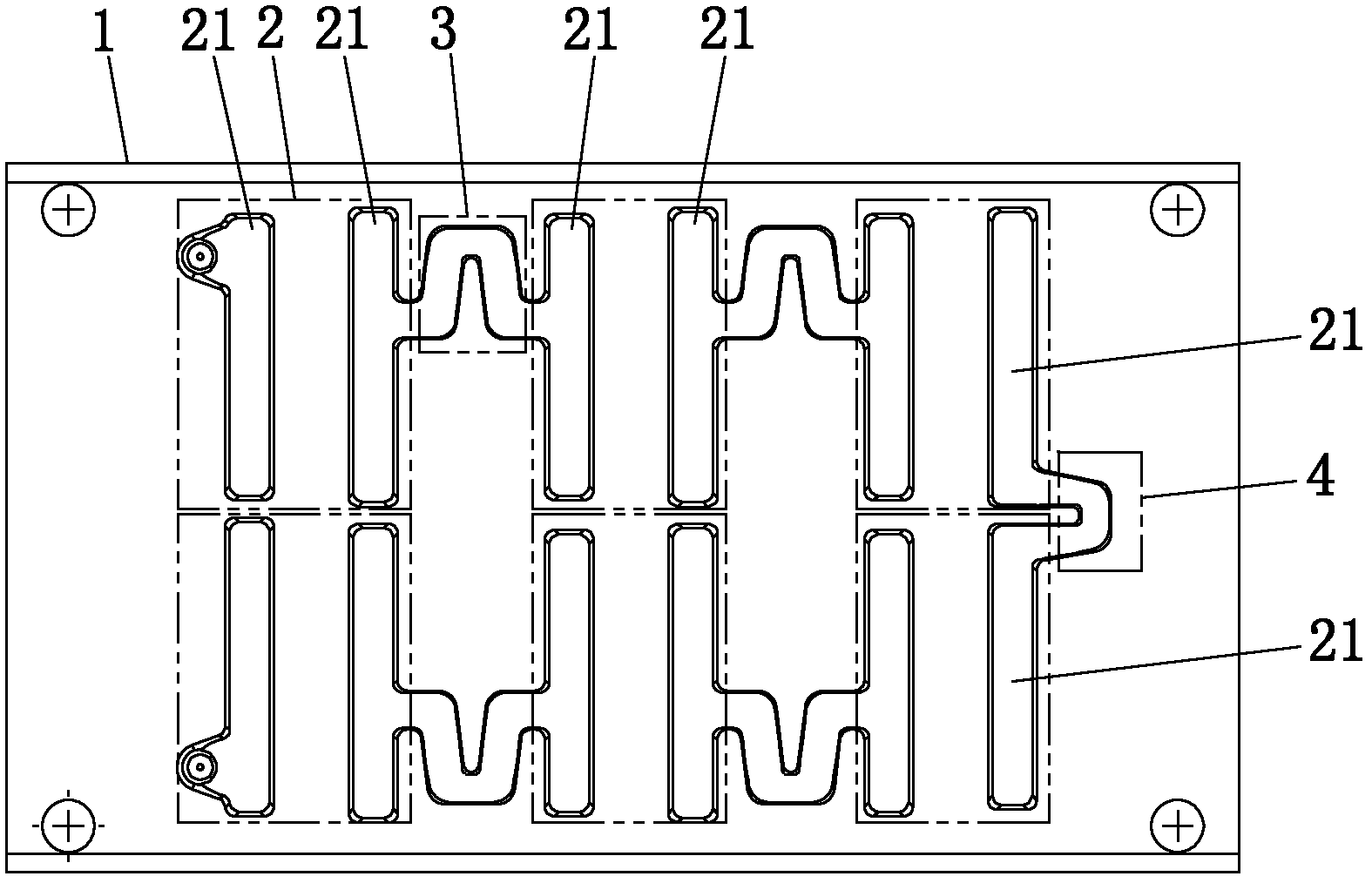

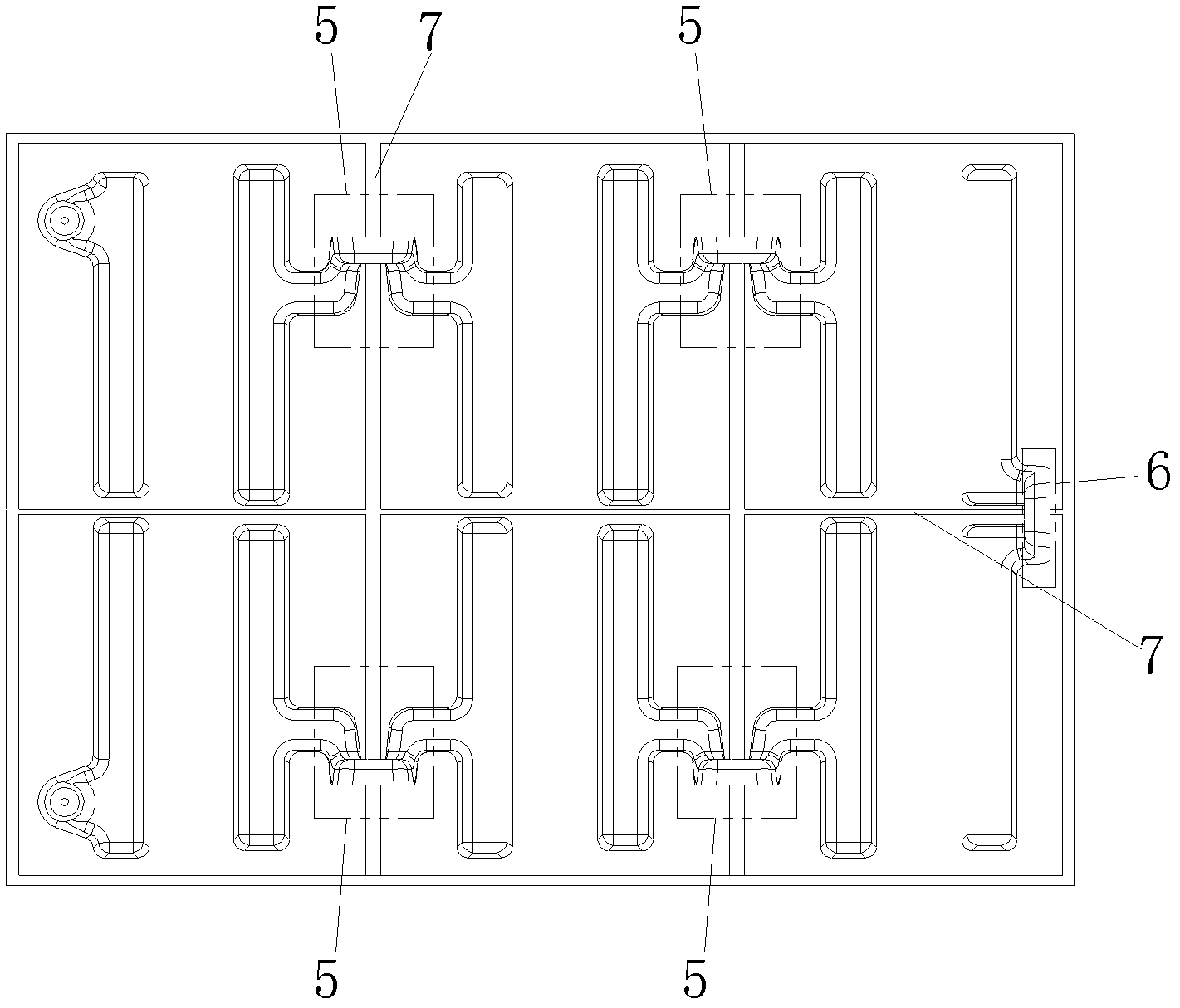

[0014] Reference figure 2 , The present invention provides a battery casting and welding mold, comprising a mold body 1, six casting units 2 distributed on the surface of the mold body 1, the six casting units 2 are arranged in sequence to form two upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com