Method for connecting carbon fiber-reinforced aluminum-based composite material and metal

A technology for strengthening aluminum-based and composite materials, applied in metal processing equipment, welding equipment, non-electric welding equipment, etc., can solve the problems of high heating temperature and deterioration of base metal performance, and achieve low ignition temperature, good metallurgical bonding, and connection quality Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

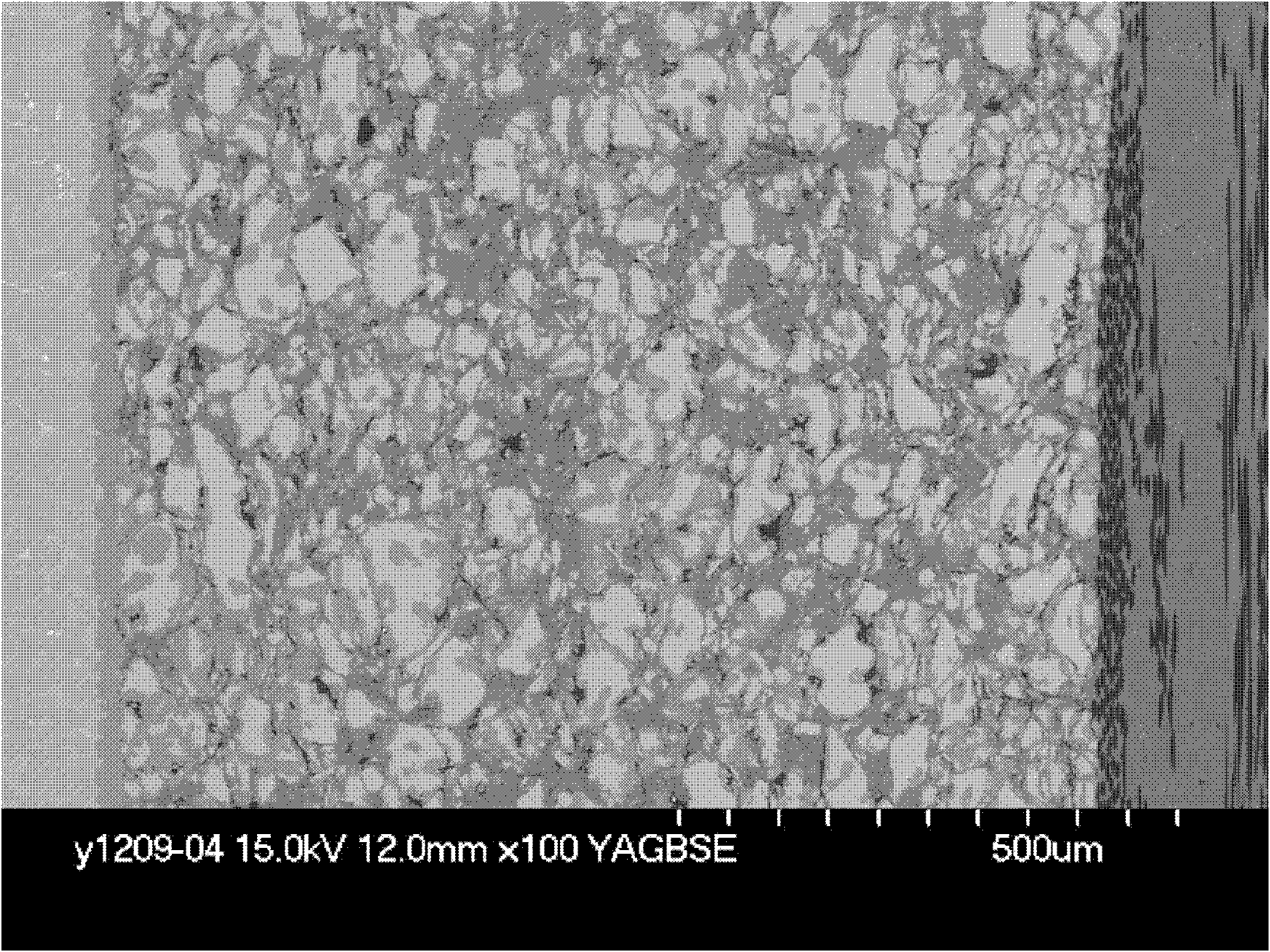

Image

Examples

specific Embodiment approach 1

[0014] Embodiment 1: In this embodiment, the method of connecting carbon fiber reinforced aluminum matrix composite material and metal is carried out according to the following steps:

[0015] Step 1, 31 to 35 parts of titanium powder with a mesh size ≥ 325 mesh, 41 to 45 parts of aluminum powder with a mesh size ≥ 325 mesh, 2 to 4 parts of nano-carbon powder, and 10 to 12 parts of tin with a mesh size ≥ 325 mesh in parts by weight powder and 9 to 11 parts of copper powder with a mesh size ≥ 325 mesh, put them in a ball mill tank, put balls in a ball-to-material mass ratio of 5:1, protect with argon, and ball mill at a speed of 300 to 500r / min for 2 ~3h to get mixed powder;

[0016] Step 2: Compress the mixed powder obtained in Step 1 into an intermediate layer with a relative density of 60% to 80% and a thickness of 1 to 3mm, and then place it in an airtight container;

[0017] Step 3. Place the intermediate layer obtained in step 2 between the aluminum matrix composite mate...

specific Embodiment approach 2

[0018] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, 32 to 34 parts of titanium powder with mesh ≥ 325 mesh, 42 to 43 parts of aluminum powder with mesh ≥ 325 mesh, 2.5 ~3.5 parts of nano carbon powder, 10.5~11.5 parts of tin powder with a mesh size ≥325 mesh and 9.5~10.5 parts of copper powder with a mesh size ≥325 mesh. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Specific embodiment three: the difference between this embodiment and specific embodiment one is: in step one, 33 parts of titanium powder with a mesh number ≥ 325 mesh, 42.5 parts of aluminum powder with a mesh number ≥ 325 mesh, and 3.0 parts of nano-carbon powder 11 parts of tin powder with a mesh size ≥ 325 mesh and 10 parts of copper powder with a mesh size ≥ 325 mesh. Other steps and parameters are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com