Method for producing threaded screws with large bearing locations

A screw and longitudinal technology, applied in the field of manufacturing screw, can solve the problem of not being able to transmit loads for a long time, and achieve the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

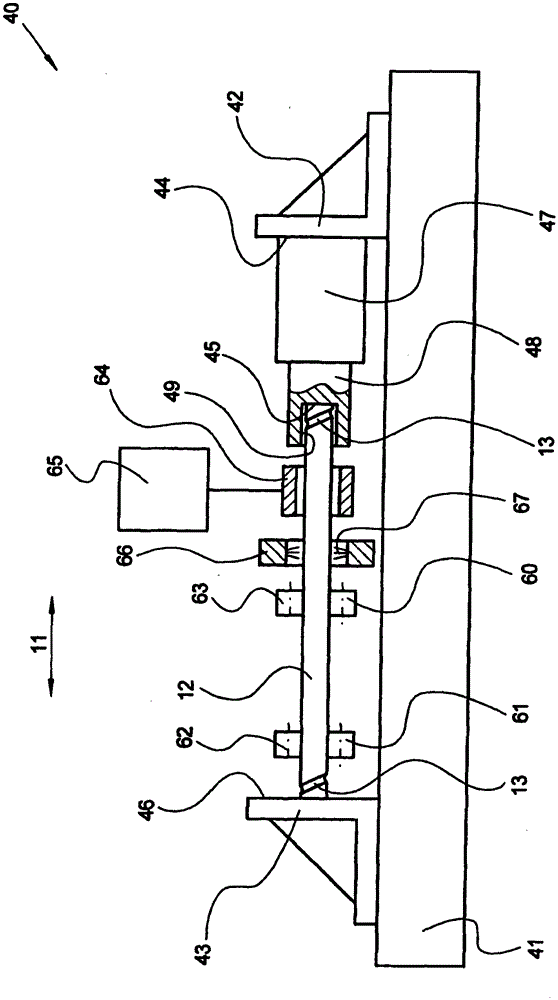

[0027] figure 1 A side view of a schematically simplified illustration of a device 40 for carrying out the method according to the invention is shown. The device 40 includes a solid base frame 41 which extends parallel to the longitudinal direction 11 of the blank 12 . A first and a second identical stop angle bracket 42 , 43 are fastened on the base frame 41 in a position-adjustable manner in the longitudinal direction 11 , so that the device 40 can be adapted to different lengths of the blank 12 . The flat stop surfaces 44 of the stop angle brackets 42 , 43 are oriented perpendicularly to the longitudinal direction 11 and face each other. On the stop surface 44 of the first stop angle 42 is fastened a hydraulic cylinder 47 whose piston rod 48 is displaceable in the longitudinal direction 11 . Instead of the hydraulic cylinder 47, a mechanical drive, in particular an electric cylinder, can also be provided, for example equipped with a particularly high load-carrying planeta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com