Variable-load broacher counterweight system and control method

A technology of variable load and counterweight, applied in non-electric variable control, fluid pressure control, control/regulation system, etc., can solve problems such as product quality impact, aggravate machine tool vibration and chatter, and achieve product quality assurance and vibration suppression. and flutter, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

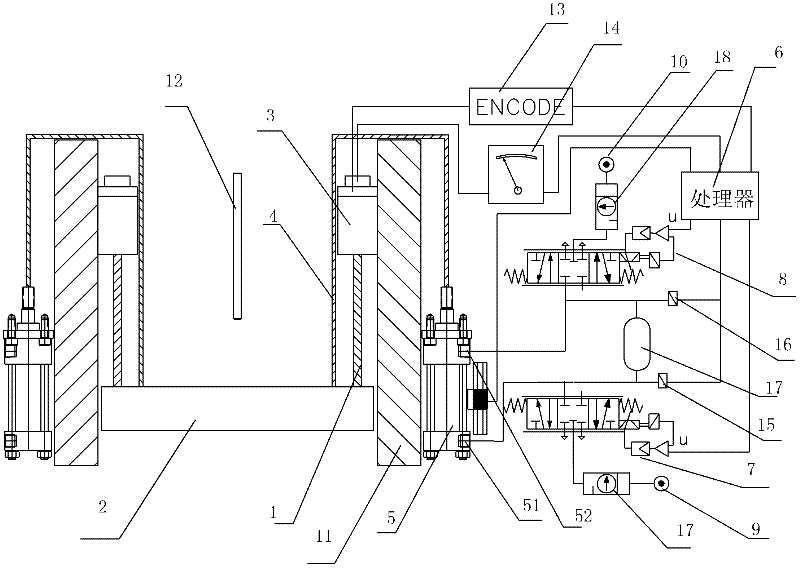

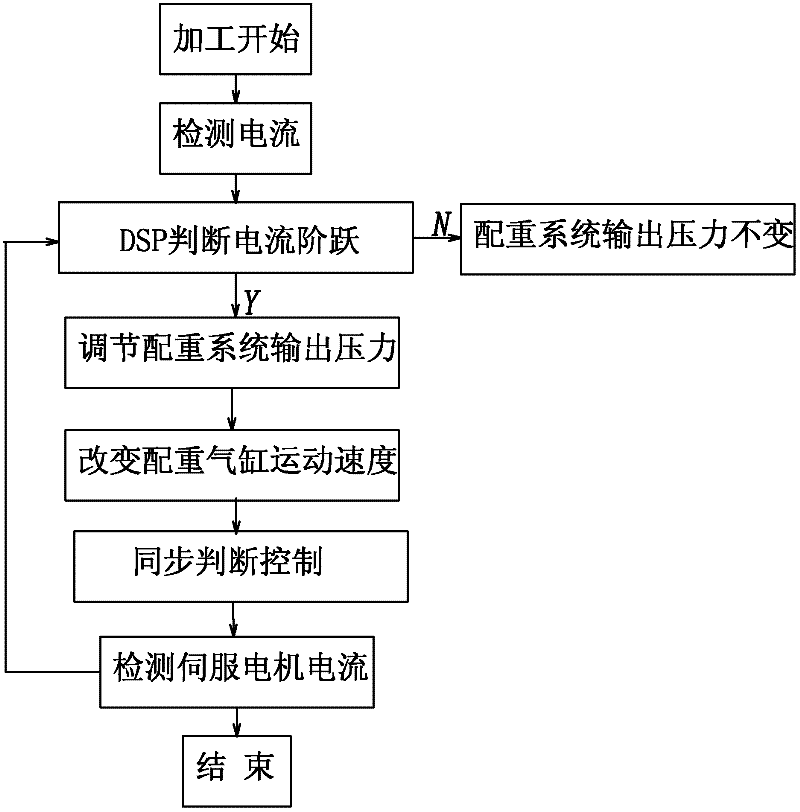

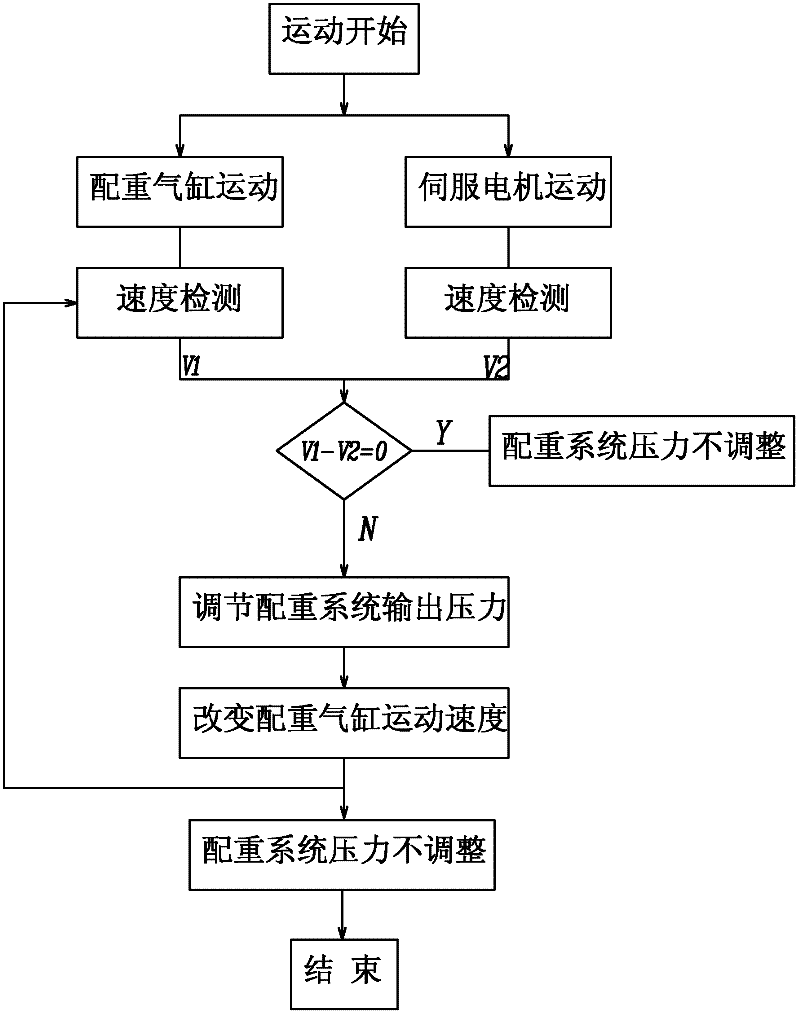

[0026] A variable load broaching machine counterweight system, including a servo motor 3 driving a broaching machine table 2 through a lead screw 1, a counterweight cylinder 5 connected to the broaching machine table 2 through a connecting rod 4, a digital signal processor 6, a An electrical servo valve 7 and a second electrical servo valve 8, the first air source 9 is connected to the first electrical servo valve 7, the second air source 10 is connected to the second electrical servo valve 8, and the servo motor 3 is connected to the digital signal via an ammeter 11 The processor 6 is connected, and the digital signal processor 6 is respectively connected with the first electric servo valve 7 and the second electric servo valve 8, and the digital signal processor 6 outputs a voltage signal U to control the first electric servo valve 7 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com