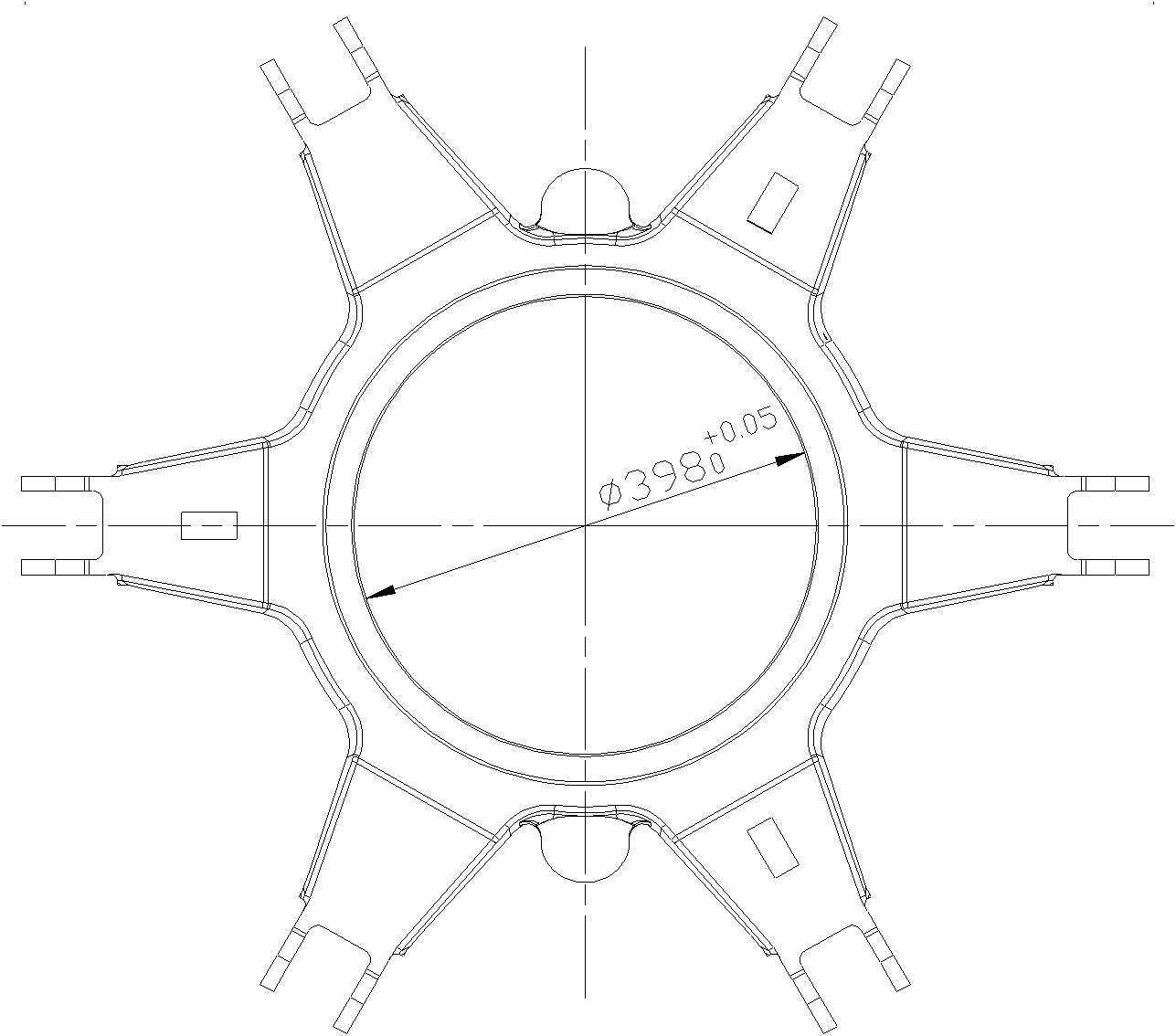

Comparison machining method for aluminum alloy discs and rings

A processing method and technology of aluminum alloy, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of poor product quality stability, difficulty in meeting assembly requirements, low processing efficiency, etc., to ensure dimensional accuracy and Consistency, meeting assembly coordination requirements, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below.

[0025] Aiming at the problem that the processing of high-precision and easily deformable disc rings of helicopter aluminum alloys is easy to deform and out of tolerance, the comparative processing method of the aluminum alloy disc ring parts of the present invention is achieved by comparing the processing compensation values of the reference parts in the clamped and free states and comparing the reference parts and The error compensation value between the assembly standard parts is used for processing compensation, so as to ensure the high precision of processing, and effectively solve the technical problem of difficult processing of helicopter aluminum alloy high-precision and easy-to-deform disc rings. The specific steps are as follows:

[0026] Step 1. Comparing the processing of reference parts:

[0027] Process a reference piece for comparative measurement and processing according to the conventio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com