Forming jig and method for pressing aeroengine mesh parts

A technology for aero-engines and parts, applied in the field of stamping and forming, can solve the problems of difficult control of blank holder force, difficult to achieve, no forming method and experience, etc., and achieves the effect of low processing conditions, broad application prospects and good promotion value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Describe the present invention below in conjunction with specific embodiment:

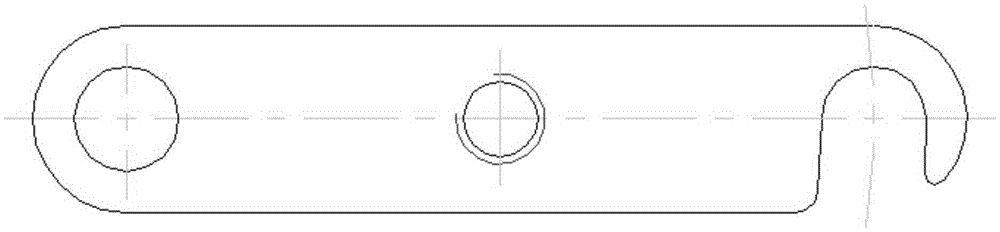

[0025] Refer to attached Figure 7 In this embodiment, an engine mesh part is taken as an example. The material of the part is made of stainless steel wires with a diameter of Φ0.14mm interlaced at 90°. After forming, the height of the part is 11mm, the diameter of the flange is Φ22mm, and the diameter of the cavity is Φ10mm.

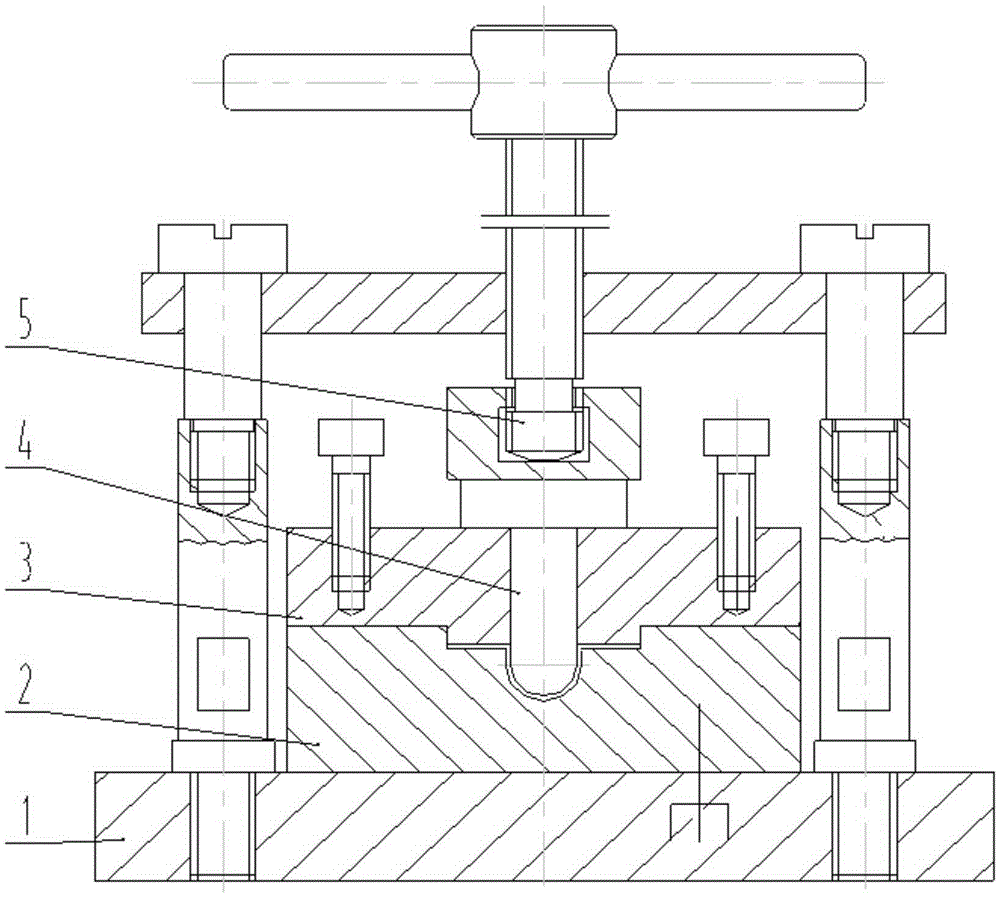

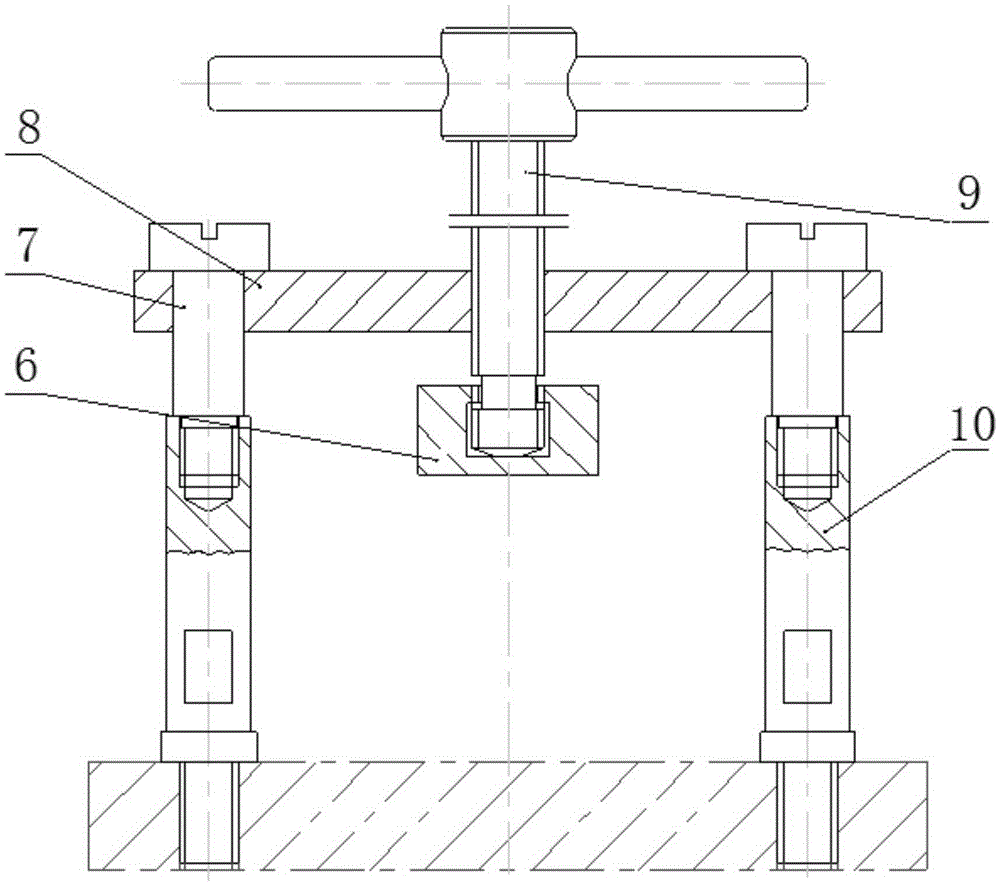

[0026] Forming fixtures used such as figure 1 As shown, it includes a base 1, a lower block 2, an upper block 3, a punch 4 and a force applying mechanism 5. The applying force mechanism includes a pillar 10, a smooth pressing block 6, a pressing screw 7, a rotary pressing plate 8 and a handle 9.

[0027] The base is a supporting part, with a square shape, and a threaded hole is designed on the left and right sides for fixing the pillar.

[0028] The material of the upper and lower blocks is CrWMn, the lower block is fixed on the base, the center of the lower block ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com