Full-automatic integrated splitting and shaping manufacturing method and device of brick material decorative surfaces

A processing method and technology for decorative surfaces, applied in the direction of stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of difficult processing, difficult to achieve imitation of natural patterns on the surface, and high requirements for the inherent performance of bricks and stone materials, so as to achieve the goal of processing Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

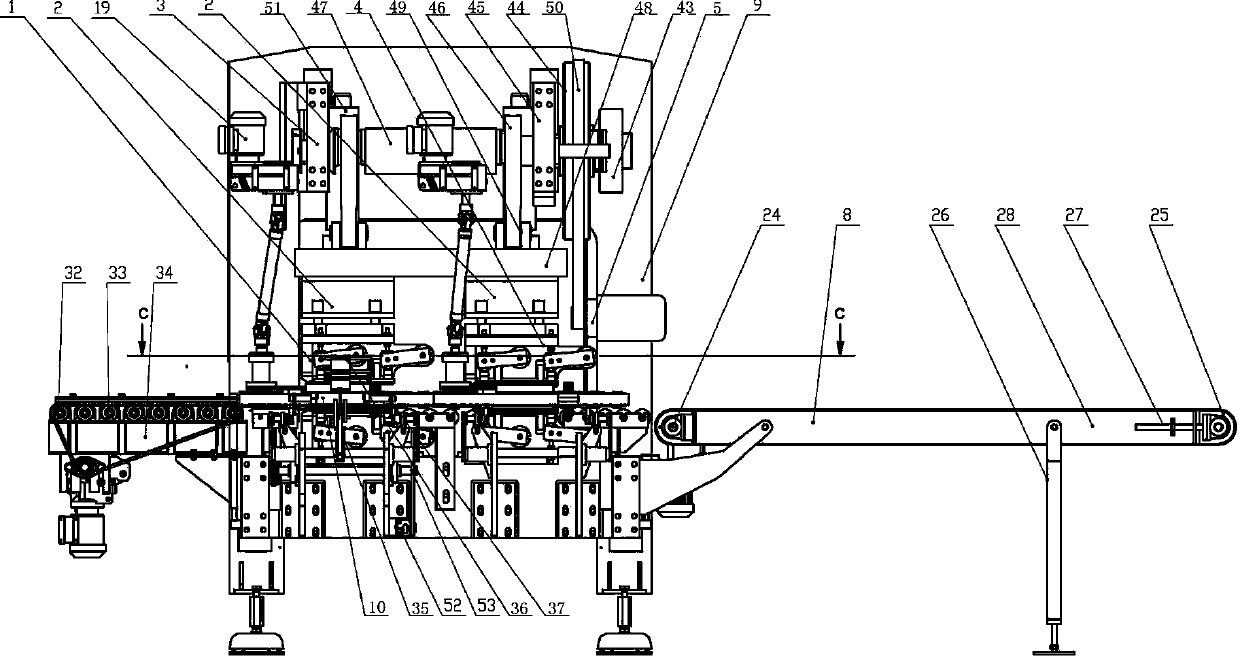

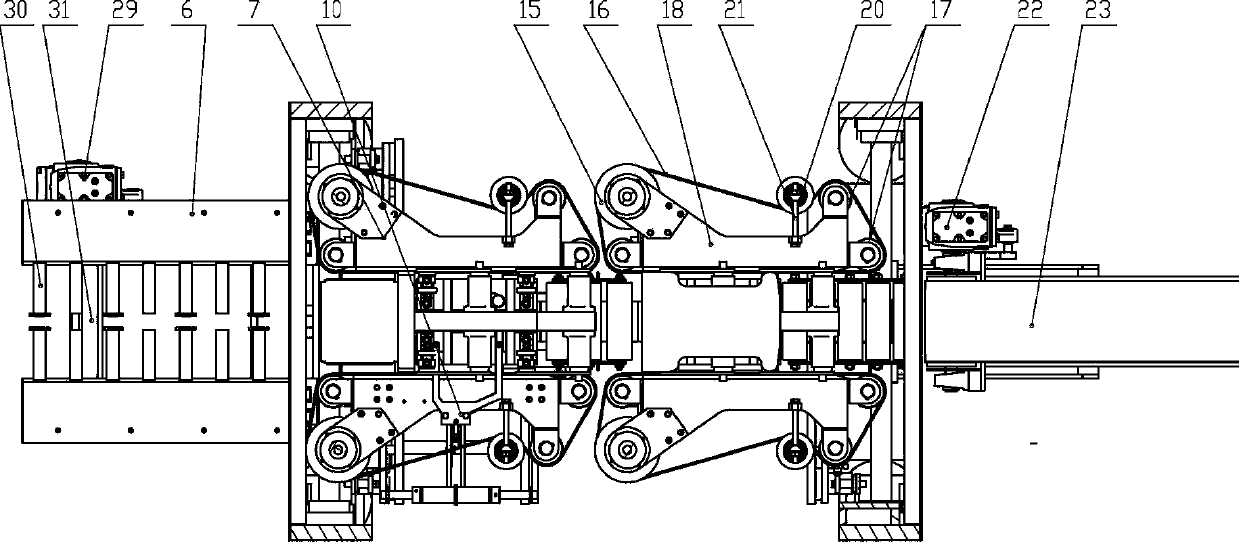

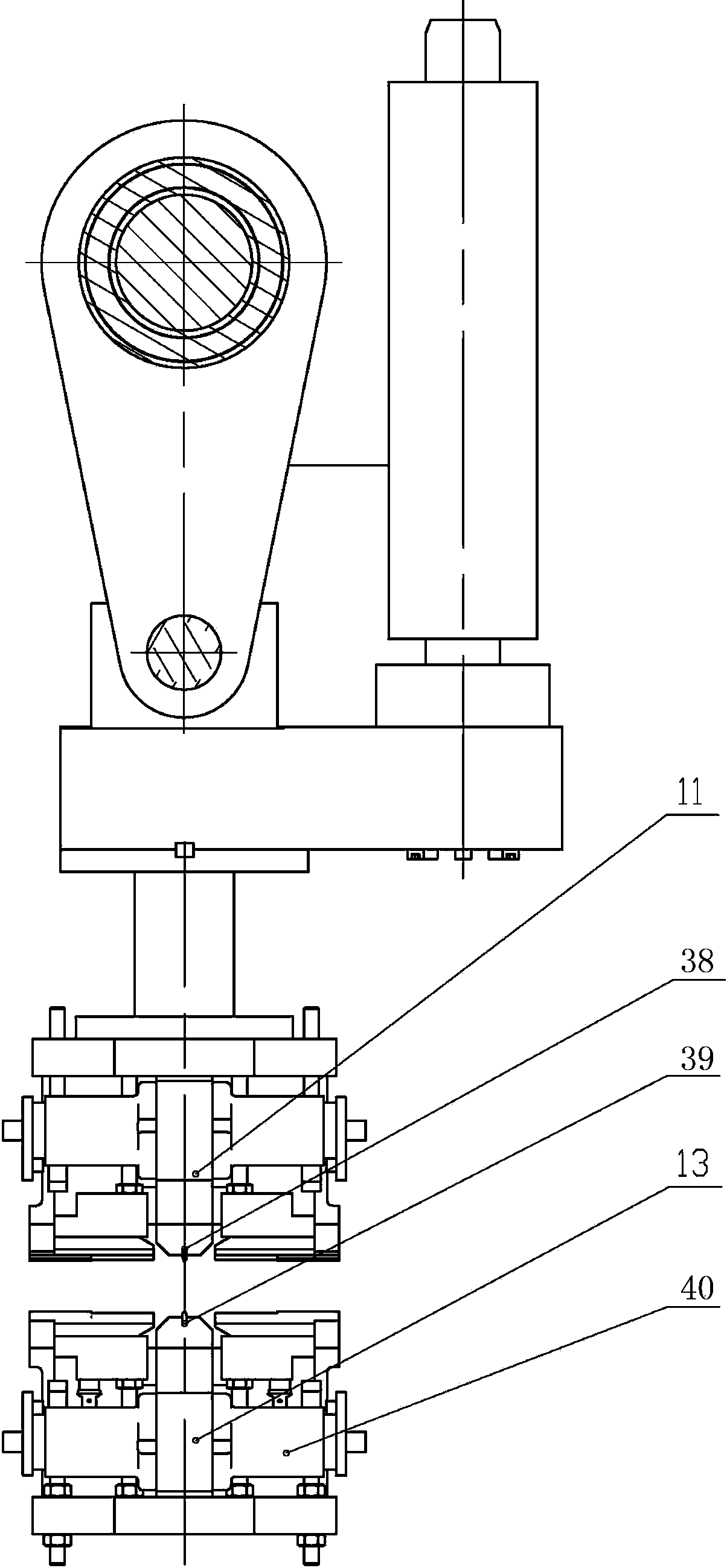

[0025] As shown in the figure, the fully automatic integrated splitting and shaping processing method for the brick decorative surface, the bricks and stones to be processed are discharged horizontally to a brick feeding mechanism 23, and the brick feeding mechanism 23 sends the bricks to the first two In the middle of a vertical, relatively parallel, independently driven vertical belt conveying device 7, the conveying device clamps the two sides of the brick and conveys it forward to the first processing procedure, and the transmission device 3 composed of a crank linkage mechanism drives the splitter The upper splitting knife of the splitting device 4 moves downward, the lower splitting knife is fixed, the upper splitting knife and the lower splitting knife jointly split the brick and stone from both sides of the brick and stone, and the two side vertical conveyor belts Convey the split bricks and stones to the middle of two vertical, relatively parallel, and independently dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com