Embossing roll set and household paper manufactured by aid of same

A technology for household paper and embossing rolls, applied in the direction of mechanical processing/deformation, can solve the problems of complex, rough, and increased cost in the papermaking process, improve the easy falling of fiber debris, increase surface smoothness, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

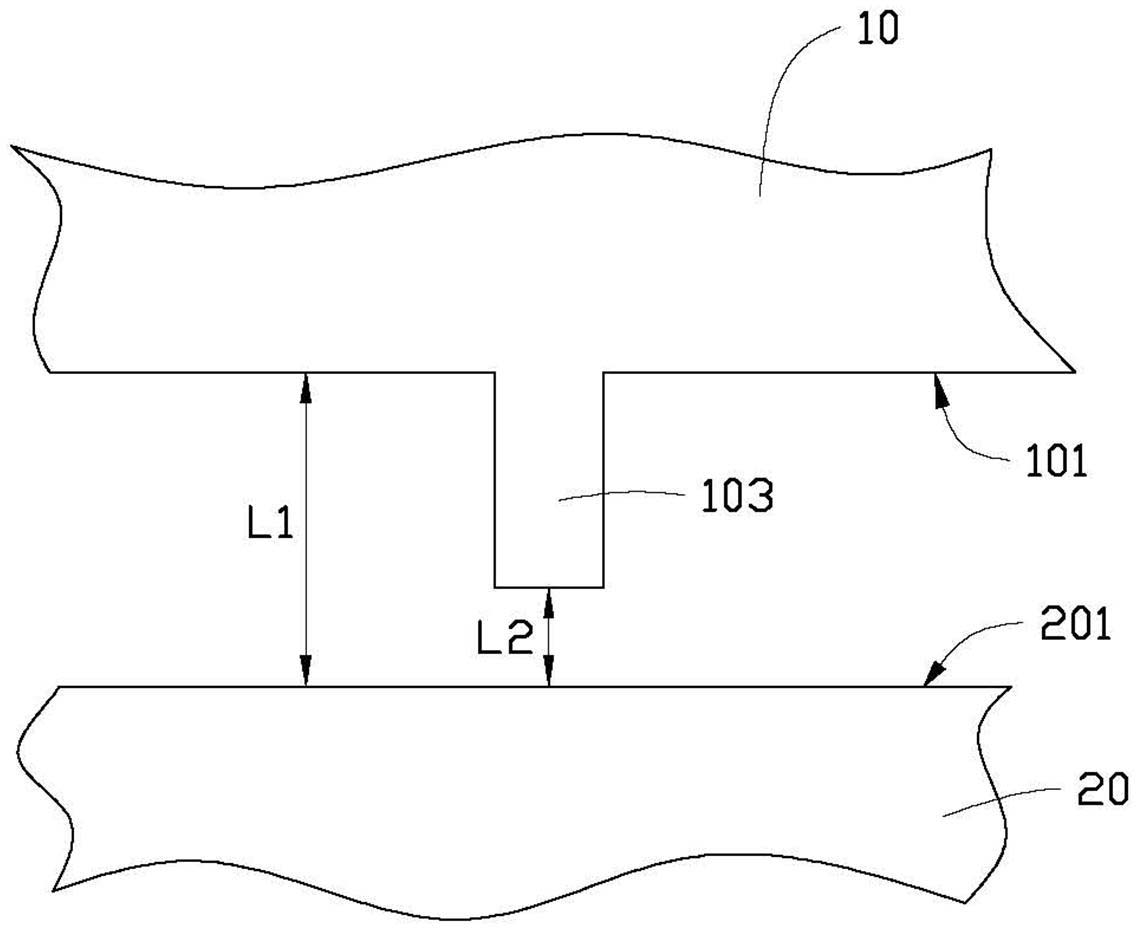

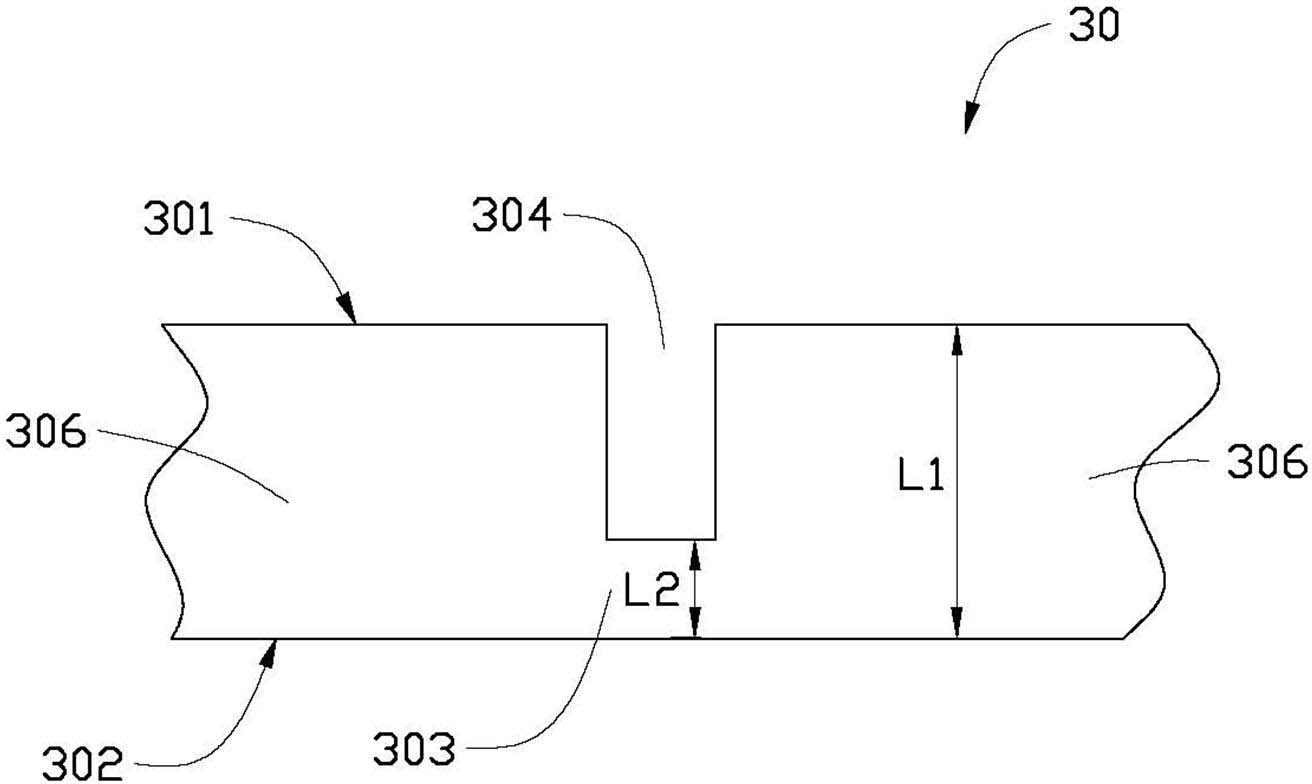

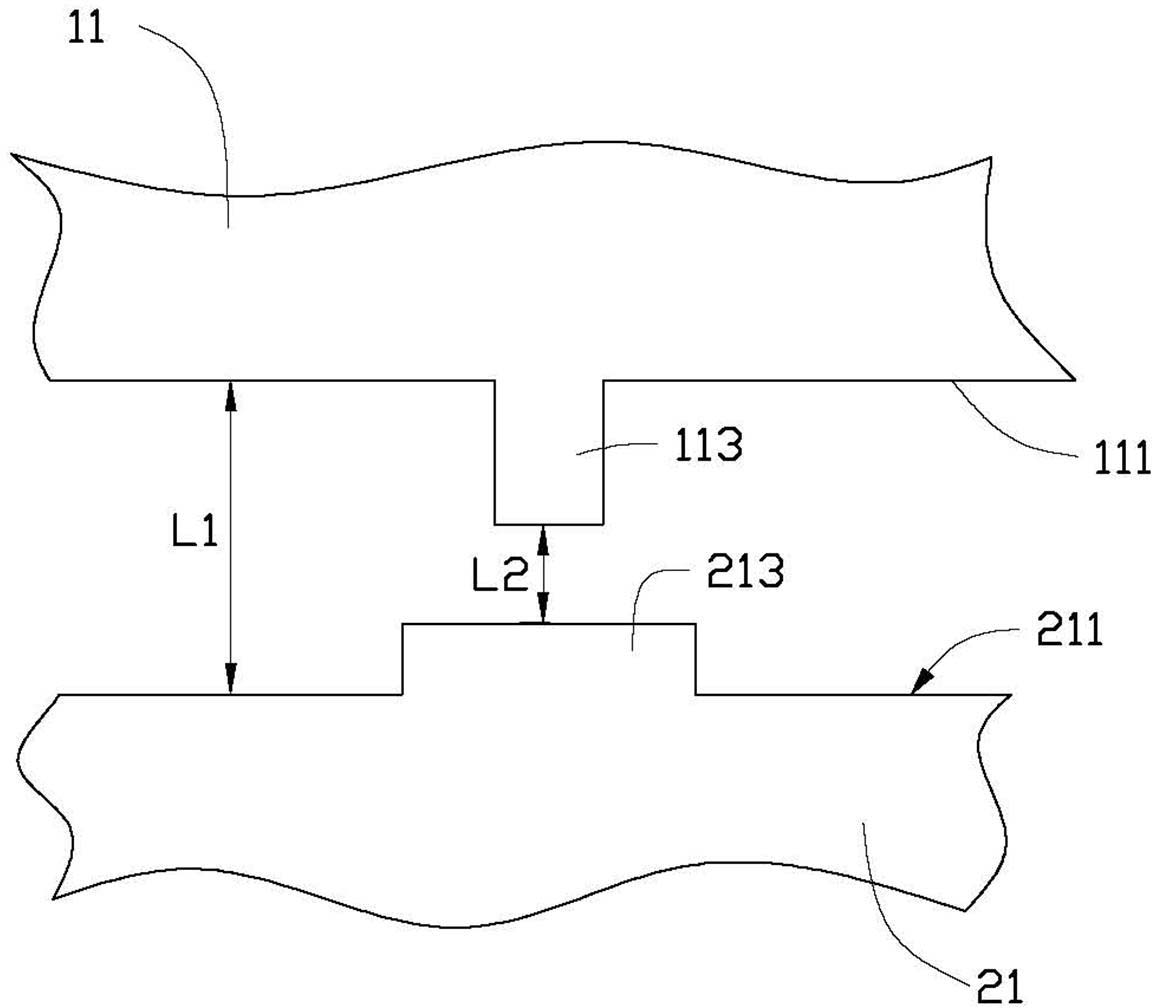

[0026] Please refer to figure 1 , The embossing roller set of the first embodiment of the present invention includes two embossing rollers 10, 20 arranged in pairs. Embossing patterns are formed on the embossing rollers 10, 20, and the embossing patterns can be edge-cut patterns mainly for lamination or various patterns with aesthetic effects. The roller surface gap between the two embossing rollers 10 and 20 of the embossing roller set is L1, and the embossing gap is L2, wherein L2<L1.

[0027] The two embossing rolls 10 , 20 each have an opposing roll surface 101 , 201 . The distance between the roll surfaces 101 , 201 of the two embossing rolls 10 , 20 is also the roll surface gap of the two embossing rolls 10 , 20 . Understandably, the distance between the roll surfaces 101, 201 of the two embossing rolls 10, 20 should refer to the two points where the straight line passing through the roll centers of the two rolls intersects the roll surfaces 101, 201 (the two points ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com