Slide rail for half-step lateral locking of vehicle seat

A vehicle seat, small step technology, applied in the direction of movable seats, etc., can solve the problems of insufficient peeling strength of the slide rail, difficulty in adjusting the sliding of the seat, etc., to improve processing and assembly process, compact appearance, improve reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

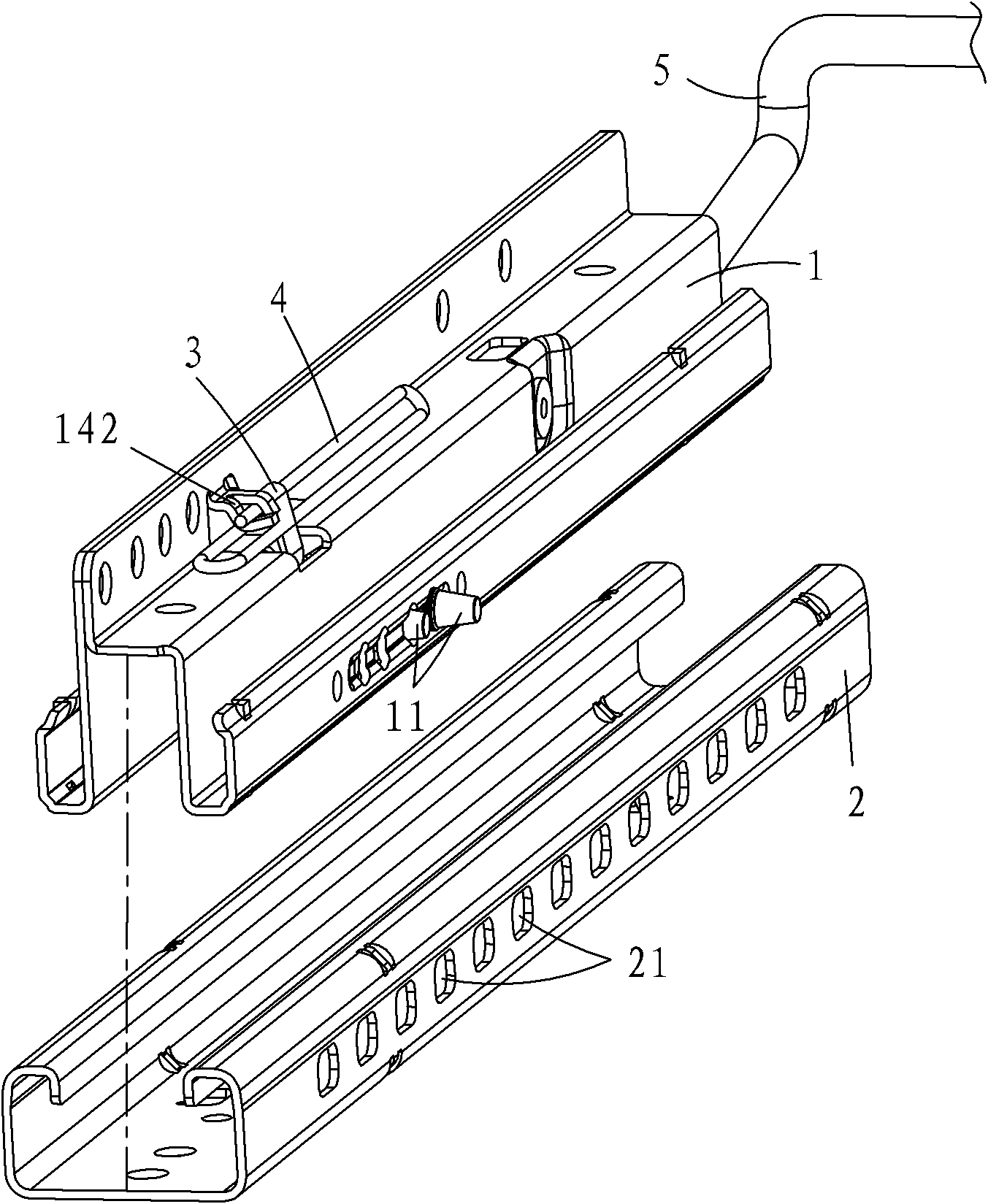

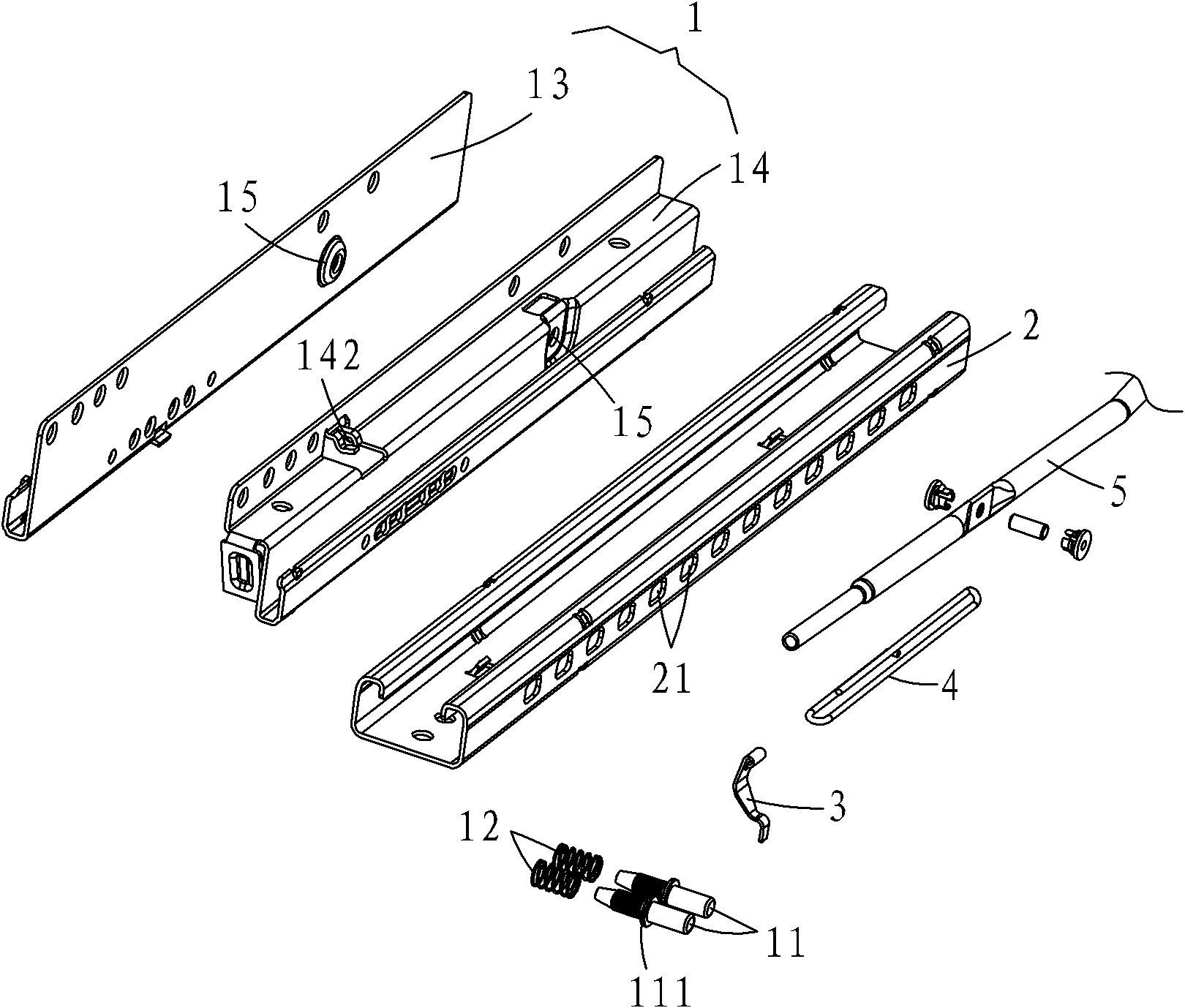

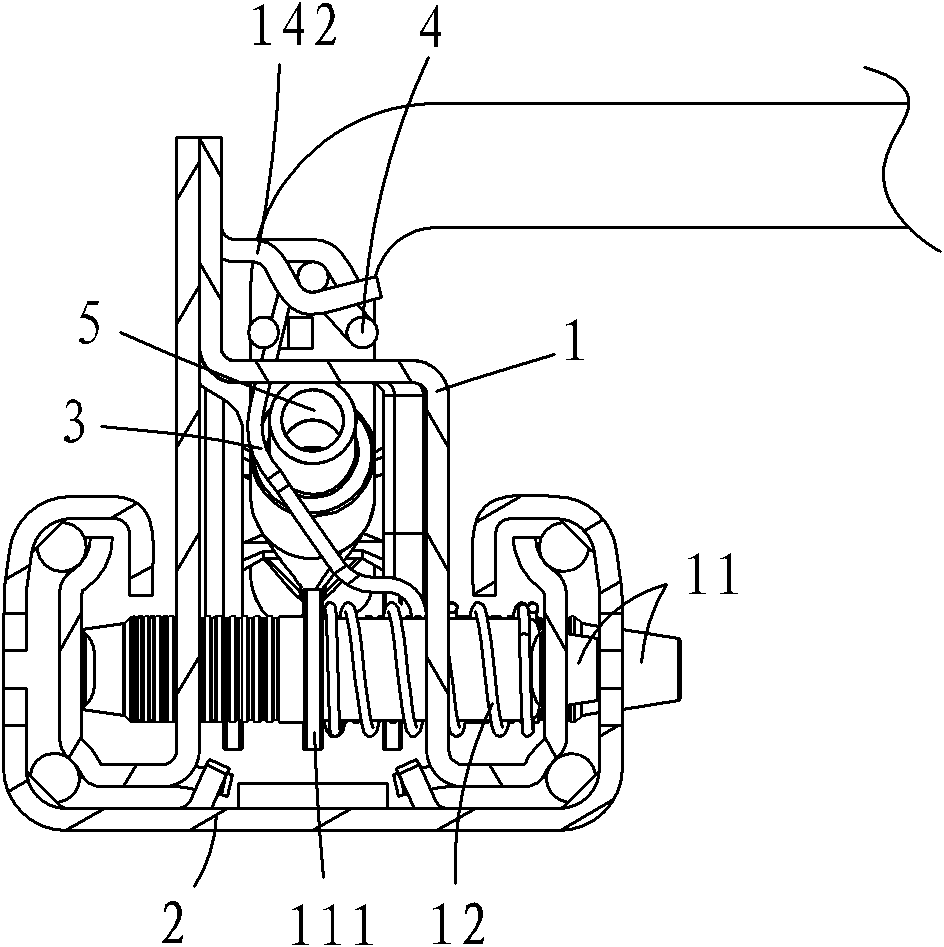

[0030] see Figure 1 to Figure 4 As shown, the small-step lateral locking vehicle seat slideway of the first embodiment of the present invention includes:

[0031] A set of upper chute 1 and lower chute 2 that can slide relatively. A plurality of limit holes 21 are provided on the side wall of the lower chute 2. The upper chute 1 is pierced with a first set of side-by-side stoppers. Pin 11, the stop pin 11 is set with a return spring 12, which is used to lock one of the limit holes 21 when the stop pin 11 is reset;

[0032] A first connecting piece 3, one end of which passes through the upper end surface of the upper chute 1, and is hinged to a torsion spring 4; the torsion spring 4 is to facilitate the reset of the first connecting piece 3, and the torsion spring 4 is fixed on the upper chute 1, the torsion spring 4 is in the shape of a paper clip, and

[0033] A handle 5 is used to move the first connecting piece 3 , so as to drive the stop pin 11 to move sideways through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com