Method for designing support on rear-axle bogie used for coach chassis assembling line

A technology of a passenger car chassis and a design method, which is applied in the directions of motor vehicles, transportation and packaging, can solve the problems of inconvenient use, increased equipment cost, low work efficiency, etc., and achieves the effects of reasonable selection of materials, simple structure and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

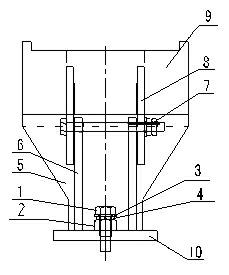

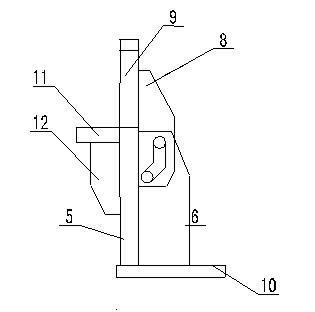

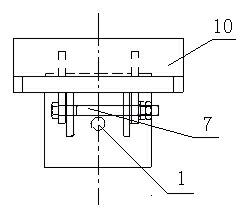

[0019] Such as figure 1 , figure 2 , image 3 As shown, the design method for supporting on the rear axle trolley of the large passenger car chassis assembly line includes a support plate 5, a connector, a reinforcing rib, and a bottom plate 10, and is characterized in that it also includes a leaf spring bridge supporting folding plate 9 and a A grooved groove plate 8 with a bent elongated hole 14, the leaf spring bridge supporting the folding plate 9 is placed on the top of the supporting plate 5, and two grooves are welded symmetrically on one side of the leaf spring bridge supporting the folding plate 9 Plate 8, the grooved plate 8 is on the same side as the two reinforcing ribs I6 welded on the support plate 5; the connecting bolt 7 passes through the two bent-shaped elongated holes 14, and can go up and down in the bent-shaped elongated holes 14 Sliding; the groove back groove plate 8 is hinged with the reinforcing rib I6 through the connecting bolt 7; the bending angl...

Embodiment 2

[0021] It is basically the same as Embodiment 1, except that the bending angle of the bent elongated hole 14 is 115°, and the connecting parts are the fastening bolt 1 and the connecting bolt 7, both of which are hexagonal bolts.

Embodiment 3

[0023] It is basically the same as the embodiment 1, except that the bending angle of the bent elongated hole 14 is 125°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com