Full-automatic and high-speed casing production line system for cupped beverage

A fully automatic, production line technology, applied to the types of packaging items, packaging, packaging bottles, etc., can solve the problems that affect the production efficiency and economic benefits of cup beverages, affect the production progress, and consume labor, so as to facilitate automation and improve production. The effect of efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the drawings:

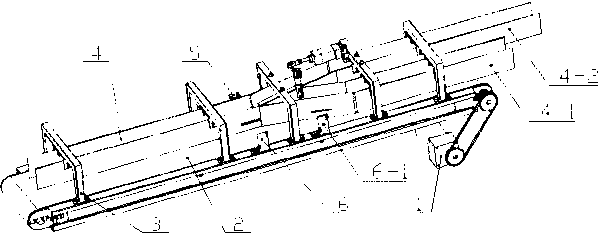

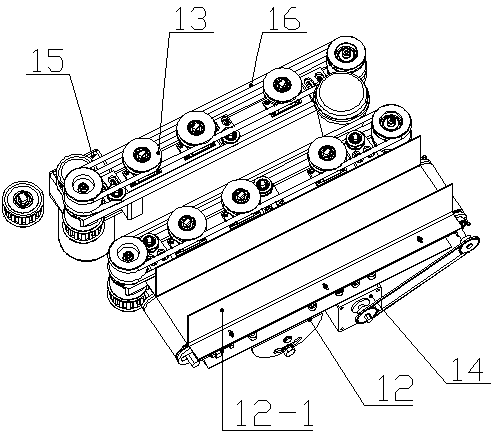

[0037] A full-automatic high-speed cup-packed beverage packaging production line system, such as figure 1 As shown, the system includes automatic diverter A, automatic posture regulator B, automatic sequencer C, automatic grouping system D, automatic boxing system E, which are sequentially set up. It also includes a control system that controls the complete work of each component. .

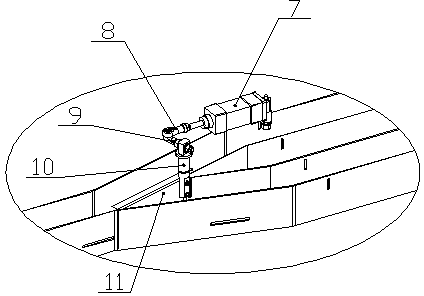

[0038] The automatic diverter A is such as figure 2 As shown, it is a belt conveyor 2 with a flow dividing function. Its function is to divide every five cups of drinks in a cup from the previous process (heat shrinkage) into a group and send them out. The motor I1 drives the belt conveyor 2 to transport the cups of drinks through the sprocket chain drive. A baffle frame 3 is built on the brackets on both sides of the belt conveyor 2. The baffle frame 3 straddles the belt conveyor and is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com