Tension control method

A technology of tension control and unwinding roller, which is applied in the field of control, can solve the problems of difficult spare parts, poor sealing performance, poor reliability, and high price, and achieve the effects of good system operation stability, simple control mode, and high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

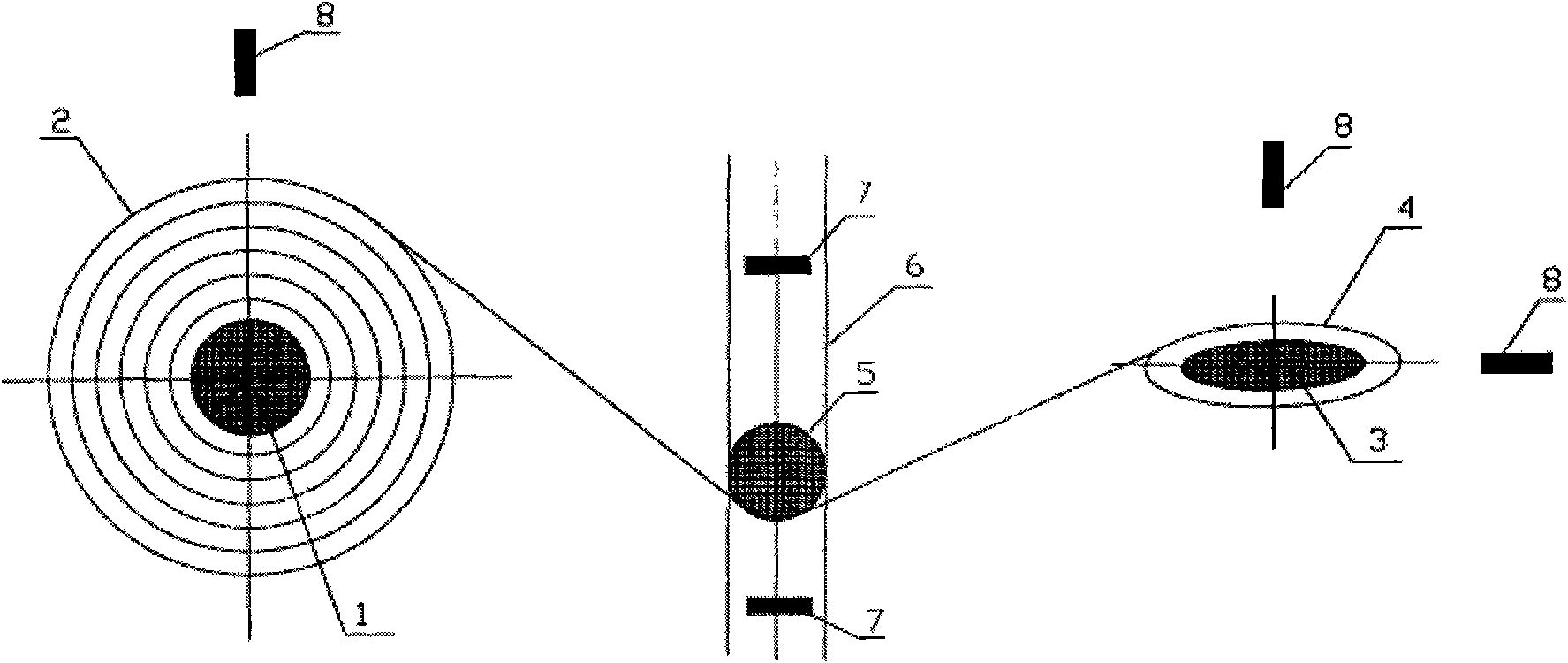

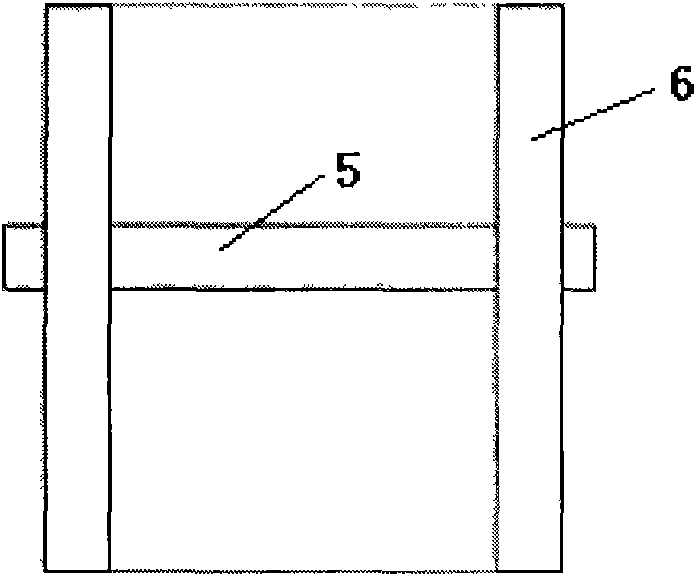

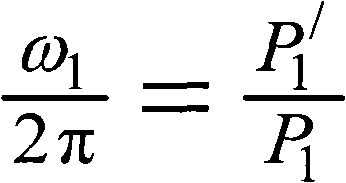

Embodiment 1

[0109] In the case that the unwinding roller and the winding roller are both cylindrical, a roll diameter measuring device is installed on the outside of the unwinding roll and the winding roll, and the instant roll diameter change value of the unwinding roll and the winding roll can be measured in real time, and Through the information input unit, it is sent to the data calculation unit, and the data calculation unit obtains the number of pulses required by the unwinding roller and the winding roller at a fixed L distance per winding through interpolation operations Further, the information is sent to the unwinding roller motor and the winding roller motor through the information output unit, and then the precise control of the tension is realized through the positional relationship.

Embodiment 2

[0111] When the unwinding roller is cylindrical and the winding roller is an elliptical cylinder, the winding roller starts at a fixed position. The roll diameter measuring device is installed on the outside of the roll, which can measure the real-time roll diameter change value of the unwinding roller and the winding roll, and send it to the data calculation unit through the information input unit, and the data calculation unit can obtain the unwinding roll and winding roll The number of pulses required by the winding roller for each winding of a fixed distance L Further, the information is sent to the unwinding roller motor and the winding roller motor through the information output unit, and then the precise control of the tension is realized through the positional relationship.

Embodiment 3

[0113] Knowing the initial winding diameter and tape thickness of the unwinding roller and the winding roller, the change value of the winding diameter of the unwinding roller and the winding roller can be obtained through calculation, and sent to the data calculation unit through the information input unit, the data calculation unit The number of pulses required by the unwinding roller and the winding roller at a fixed distance L per winding is obtained by interpolation Further, the information is sent to the unwinding roller motor and the winding roller motor through the information output unit, and then the precise control of the tension is realized through the positional relationship.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com