Bainitic steel and preparation method thereof

A technology of bainite steel and cooling method, which is applied in the field of metal materials, can solve the problems of large strength fluctuation range and unstable strength of low-carbon bainite steel, and achieve the effect of good strength stability and stable strength index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The present invention also provides a kind of preparation method of bainite steel, comprises the following steps:

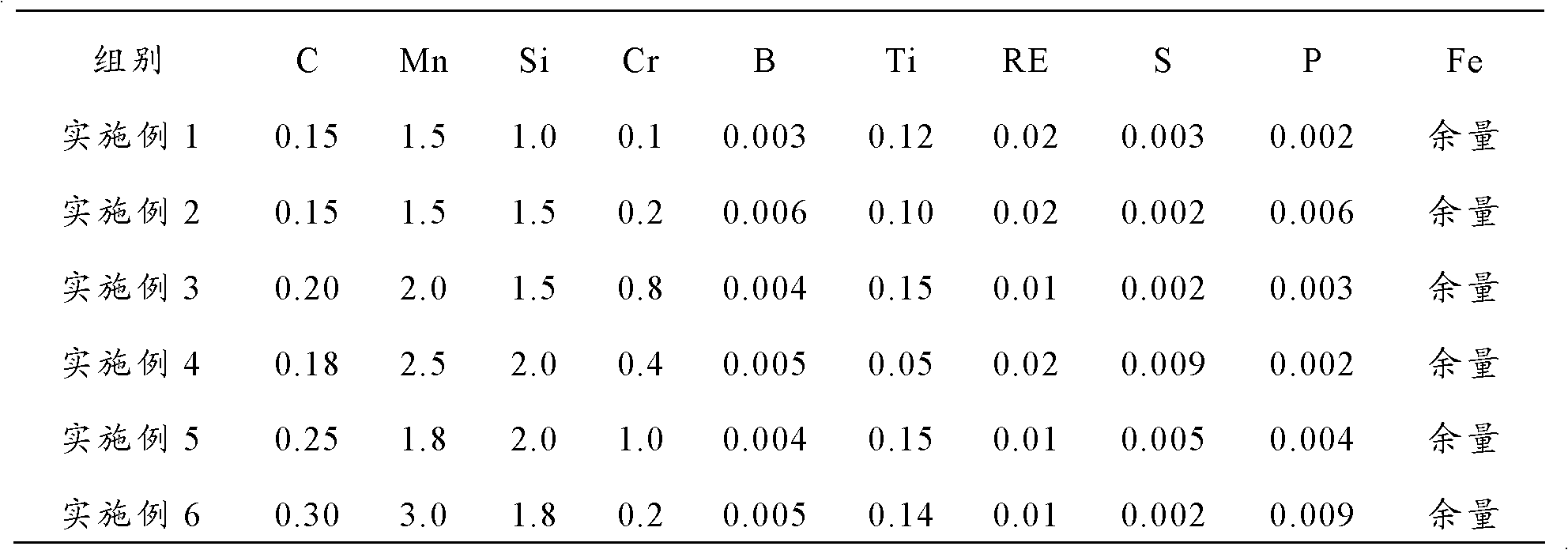

[0054] a), casting an ingot with the following composition:

[0055] 0.1wt%-0.3wt% C, 1.5wt%-3.0wt% Mn, 1.0wt%-2.0wt% Si, 0.003wt%-0.006wt% B, 0.05wt%-0.15wt% Ti, Greater than zero and less than or equal to 1.0wt% of Cr, greater than zero and less than or equal to 0.03wt% of RE, 0-0.01wt% of S, 0-0.01wt% of P and the balance of Fe;

[0056] b), heat-treating the ingot, specifically:

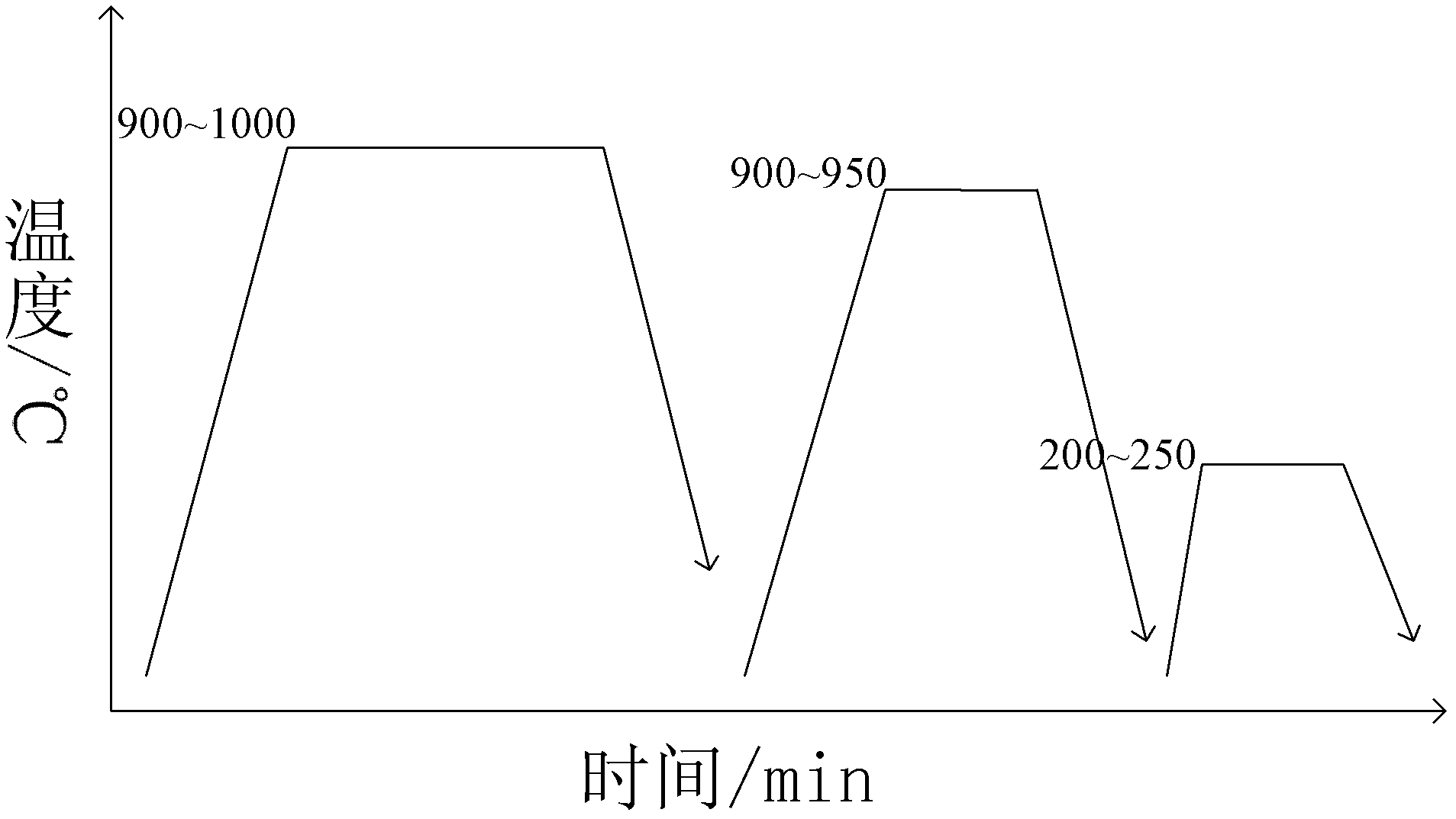

[0057] b01), heating to 900℃~1000℃ for pre-normalizing treatment;

[0058] b02), heating the ingot obtained in step b01) to 900°C to 950°C for secondary normalizing treatment;

[0059] b03), heating the ingot obtained in step b02) to 200° C. to 250° C. for tempering treatment to obtain bainite steel.

[0060] Step a) is a casting process, and the present invention has no special limitation on the casting method described in step a), which can be sand casting or metal cast...

Embodiment 1

[0070] (1) prepare an ingot, and the ingot composition is listed in Table 1;

[0071] (2) heating the ingot obtained in step (1) to 900° C. for 60 minutes and then air cooling;

[0072] (3) reheating the ingot obtained in step (2) to 900° C. for 30 minutes and air cooling;

[0073] (4) Reheating the cast ingot obtained in step (3) to 200° C. for 90 minutes to obtain bainitic steel.

[0074] The bainite steel prepared according to the above method was tested for hardness, and the results are shown in Table 2.

Embodiment 2

[0076] (1) prepare an ingot, and the ingot composition is listed in Table 1;

[0077] (2) heating the ingot obtained in step (1) to 1000° C. for 120 minutes and air cooling;

[0078] (3) reheating the ingot obtained in step (2) to 950° C. for 60 minutes and then air cooling;

[0079] (4) Reheating the ingot obtained in step (3) to 250° C. for 120 minutes to obtain bainite steel.

[0080] The bainite steel prepared according to the above method was tested for hardness, and the results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com