Light filled core mold structure and manufacturing method thereof

A manufacturing method and technology of filling cores, applied in building structures, building components, floor slabs, etc., can solve the problems of corrosion of steel bars, high production costs, slow manufacturing speed, etc., achieve good strength and stability, low production costs, Create fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for manufacturing a lightweight filled mandrel provided in this embodiment comprises the following steps:

[0028] (101) The foam material is used as a core mold, and the surface of the core mold is covered with fiber mesh cloth.

[0029] The so-called foam materials include soft foam materials and structural foam materials, among which light foam materials are preferred, and polyphenylene is more preferred.

[0030] The so-called fiber mesh cloth has good alkali resistance, flexibility, and transverse and longitudinal tensile strength, and can be glass fiber mesh cloth or wall mesh cloth.

[0031] The surface is covered with fiber mesh cloth, and the fiber mesh cloth can completely surround the mandrel.

[0032] (102) Spray mortar on at least one side of the mandrel, and solidify it into shape.

[0033] Spraying mortar to the mandrel covered by the fiber mesh cloth can be sprayed on one side of the mandrel, or can be sprayed on multiple faces of the mandrel,...

Embodiment 2

[0041] (201) Select polyphenylene as the core mold, and cover the surface of the core mold with fiber mesh cloth.

[0042] So-called fiber scrims can cover multiple layers.

[0043] (202) Spray mortar on at least one side of the mandrel, and solidify and form it.

[0044] The spray mortar can be sprayed by mechanical spraying method.

[0045] Wherein, the sprayed mortar can be cement mortar and / or anti-crack mortar; the mortar can be powder mortar or fluid mortar.

[0046] The so-called mortar can also be formed by mixing the following components: 40-55% by weight of Portland cement, 2-6% by weight of adhesive, 33-40% by weight of aggregate, 5-12% by weight Heavy calcium in parts by weight, wood fiber and short glass fiber mixture in 0.5-1.5 percent by weight, plasticizer in 0.3-1.5 percent by weight.

[0047] Among them, the adhesive, aggregate, heavy calcium, wood fiber and short glass fiber mixture, and plasticizer can be dispersed and stirred to obtain a mixture; Portla...

Embodiment 3

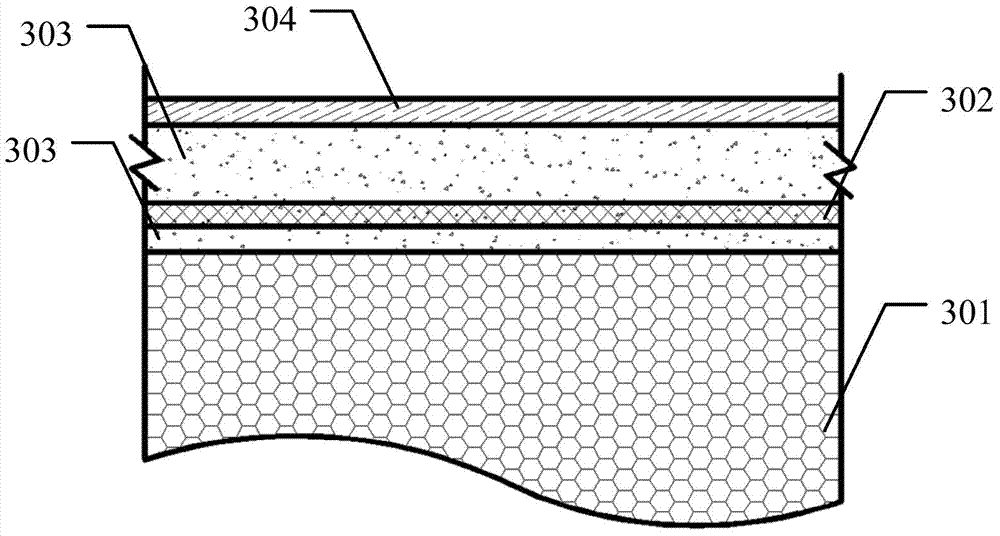

[0053] Describe in detail through accompanying drawing and embodiment below, please refer to figure 1 , figure 1 It is a structural schematic diagram of a lightweight filled mandrel structure of the present invention.

[0054] A lightweight filled mandrel structure in this embodiment includes a foam material layer 301, at least one layer of grid cloth 302, a mortar layer 303 and a wrapping film 304, a foam material layer 301, a grid cloth 302 and a wrapping film 304 Connected in sequence, the mortar layer 303 penetrates between the foam material layer 301 and the wrapping film 304 , and is fused with the grid cloth 302 .

[0055] The mortar layer 303 is used to strengthen and fix the foam material layer 301 , and the wrapping film 304 is used to tightly wrap the foam material layer 301 and the mortar layer 303 .

[0056] The so-called foaming material layer 301 can be polyphenylene layer, and this foaming material is preferably polyphenylene; The so-called grid cloth 302 pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com