A method for producing high-formability steel plates using a medium-heavy plate rolling mill and the steel plates produced therefor

A high-forming, steel plate technology, used in the manufacture of converters and other directions, can solve the problems of low strength level, elongation and low temperature impact value, difficult to meet the processing conditions of downstream users, affecting elongation and low temperature impact, etc. Improve performance, eliminate mixed crystal defects, and have good cold bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

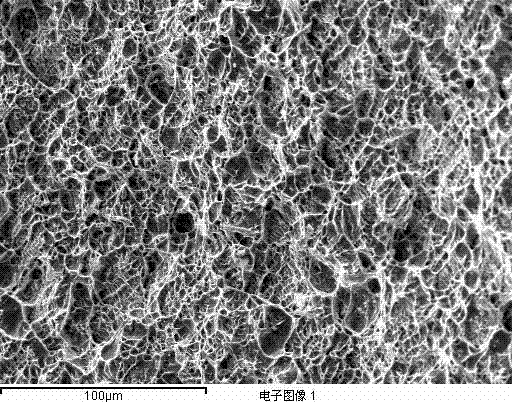

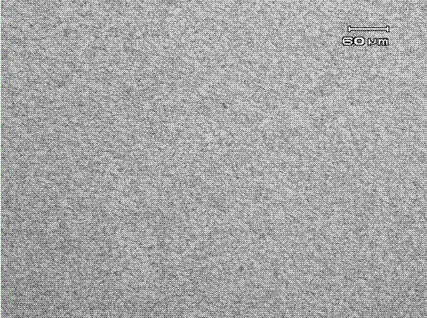

Image

Examples

Embodiment 1

[0054] A method for producing a high-formability steel plate using a plate rolling mill, comprising the following steps:

[0055] (1) Desulfurization treatment of KR molten iron: During the desulfurization treatment process of KR molten iron, the temperature of molten iron after pretreatment is controlled at 1356°C, and the weight percentage of S in the treated molten iron is 0.001%.

[0056] (2) Converter smelting: During the converter smelting process, the weight percentages of the components at the end of the converter are controlled at C 0.041%, Si 0.0045%, S 0.009%, and P 0.012%, and the temperature at the end of the converter is controlled at 1640°C; Slag melting, high gun position as soon as possible to slag dephosphorization; ensure that the end point temperature and carbon hit at the same time, require a carbon pulling operation, and point blowing is strictly prohibited to reduce the hydrogen and nitrogen content of molten steel; use slag stoppers and slag stop rods to...

Embodiment 2

[0076] A method for producing a high-formability steel plate using a plate rolling mill, comprising the following steps:

[0077] (1) Desulfurization treatment of KR molten iron: During the desulfurization process of KR molten iron, the temperature of molten iron after pretreatment is controlled at 1371°C, and the weight percentage of S in the treated molten iron is 0.003%.

[0078] (2) Converter smelting: During the converter smelting process, the weight percentages of the components at the end of the converter are controlled at C 0.056%, Si 0.0005%, S 0.010%, and P 0.086%, and the temperature at the end of the converter is controlled at 1645°C; Slag melting, high gun position as soon as possible to slag dephosphorization; ensure that the end point temperature and carbon hit at the same time, require a carbon pulling operation, and point blowing is strictly prohibited to reduce the hydrogen and nitrogen content of molten steel; use slag stoppers and slag stop rods to stop slag...

Embodiment 3

[0097] A method for producing a high-formability steel plate using a plate rolling mill, comprising the following steps:

[0098] (1) KR hot metal desulfurization treatment: During the KR hot metal desulfurization process, the temperature of the hot metal after pretreatment is controlled at 1367°C, and the weight percentage of S in the treated hot metal is 0.002%.

[0099] (2) Converter smelting: During the converter smelting process, the weight percentages of the components at the end of the converter are controlled at C 0.061%, Si 0.003%, S 0.008%, and P 0.010%, and the temperature at the end of the converter is controlled at 1650°C; Slag melting, high gun position as soon as possible to slag dephosphorization; ensure that the end point temperature and carbon hit at the same time, require a carbon pulling operation, and point blowing is strictly prohibited to reduce the hydrogen and nitrogen content of molten steel; use slag stoppers and slag stop rods to stop slag discharge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com