One-step spinning and winding complex for bi-shrinkable composite fibers

A composite fiber and combined device technology, which is applied in the field of manufacturing devices for differential shrinkage composite fibers, can solve the problems of poor cohesion between fully drawn yarns and pre-oriented yarns, affecting the quality of composite fibers, etc., so as to increase the cohesion and cohesion. good, well-made effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

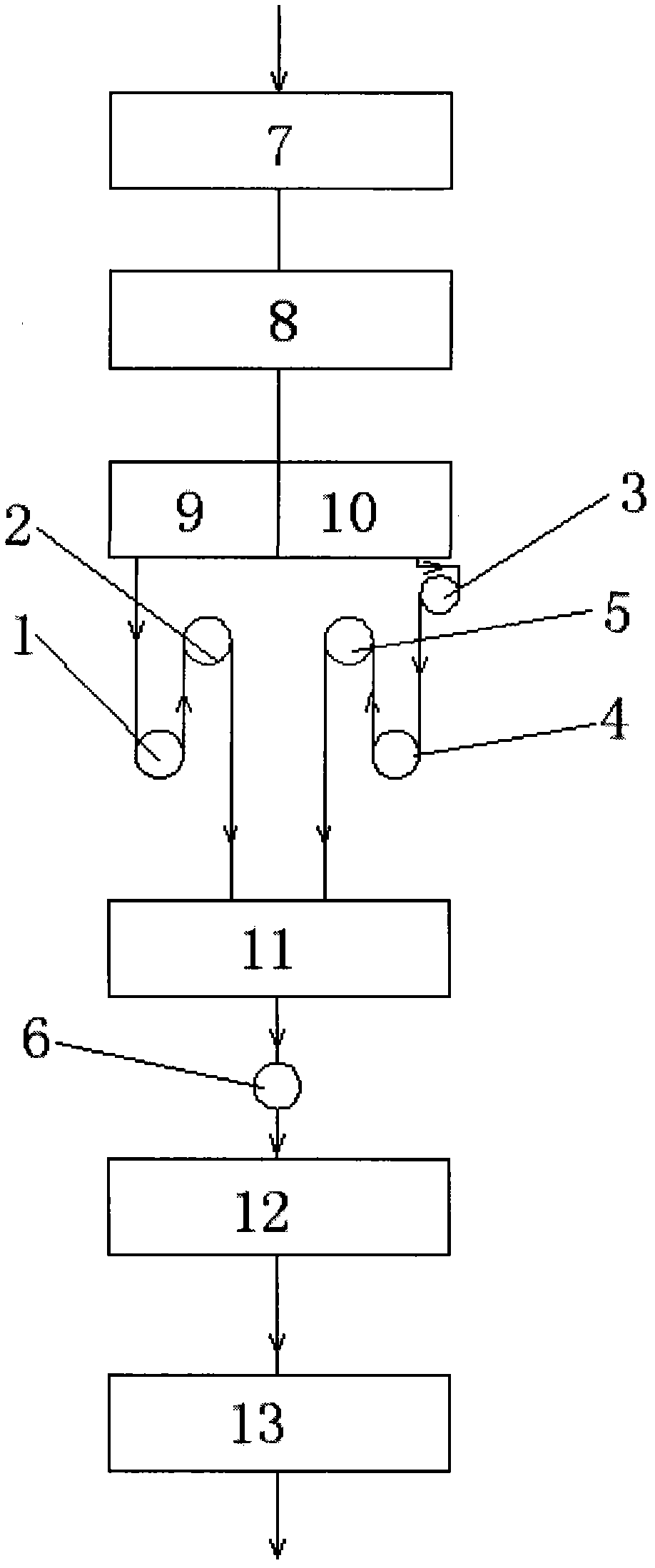

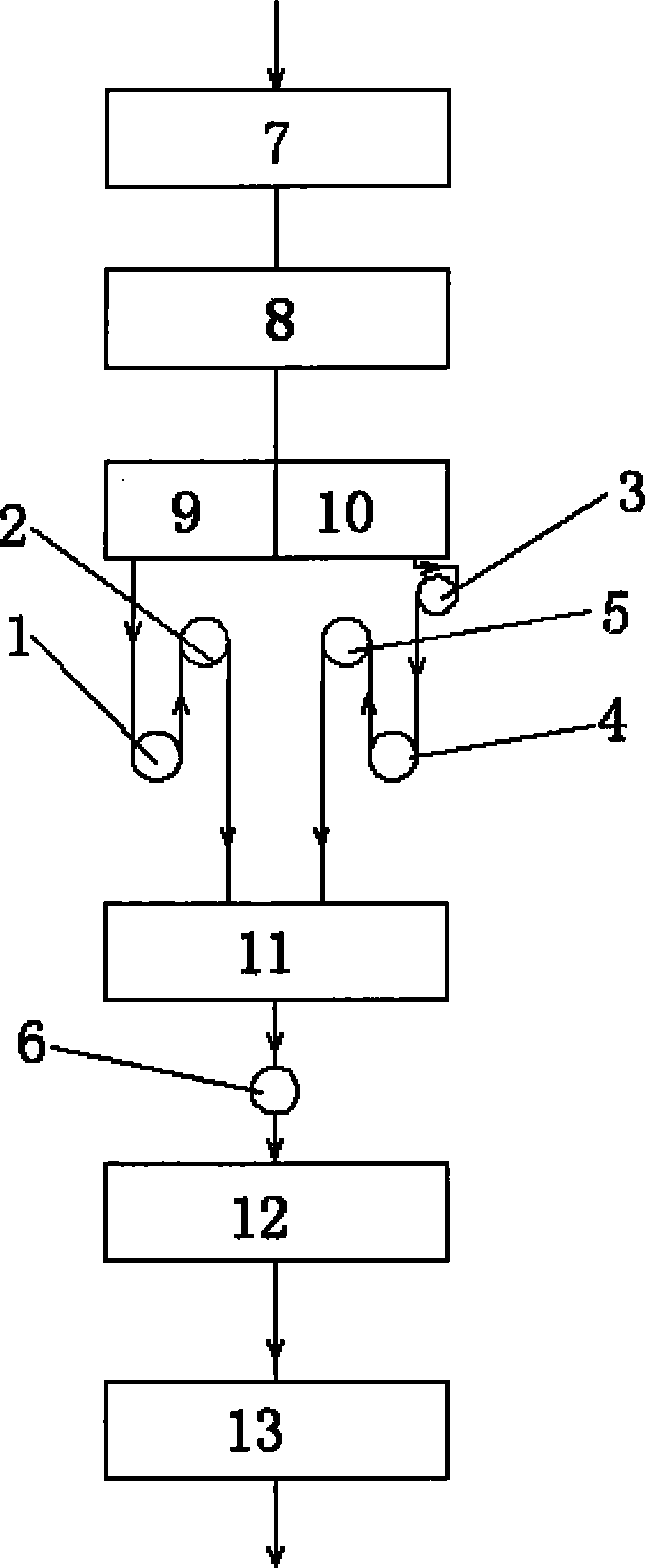

[0010] Embodiment: A combined spinning and winding device for one-step double-shrinkage composite fibers, the heater 7 is connected to the screw 8, the screw is respectively connected to the first sub-box 9 and the second sub-box 10, and the first sub-box is connected to the first heat conducting Roller 1, the first heat conduction roll is connected with the second heat conduction roll 2, the second sub-box is connected with the wire guide 3, the wire guide is connected with the first wire guide roll 4, the first wire guide roll is connected with the second wire guide roll 5, the second The heat conduction roll and the second godet roll are connected to the doubling device, the doubling device 11 is connected to the third heat conduction roll 6 , the third heat conduction roll is connected to the network device 12 , and the network device is connected to the winding device 13 .

[0011] The raw materials are heated in the heater and dried by air to remove moisture, and then the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com