Dispersing and active one bath dyeing technology of polyester-cotton fabric

A technology of reactive dyes and disperse dyes, applied in the field of polyester-cotton fabric dyeing technology, can solve the problems of consuming a lot of water, energy, printing and dyeing enterprises are difficult to overcome, and the one-time success rate is difficult to control, so as to achieve low emission and easy control of shade , the effect of stable dyeing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

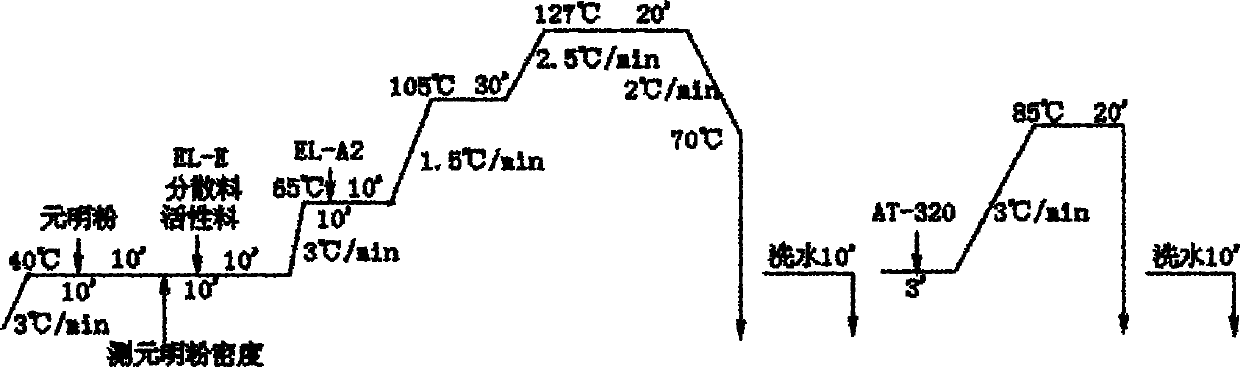

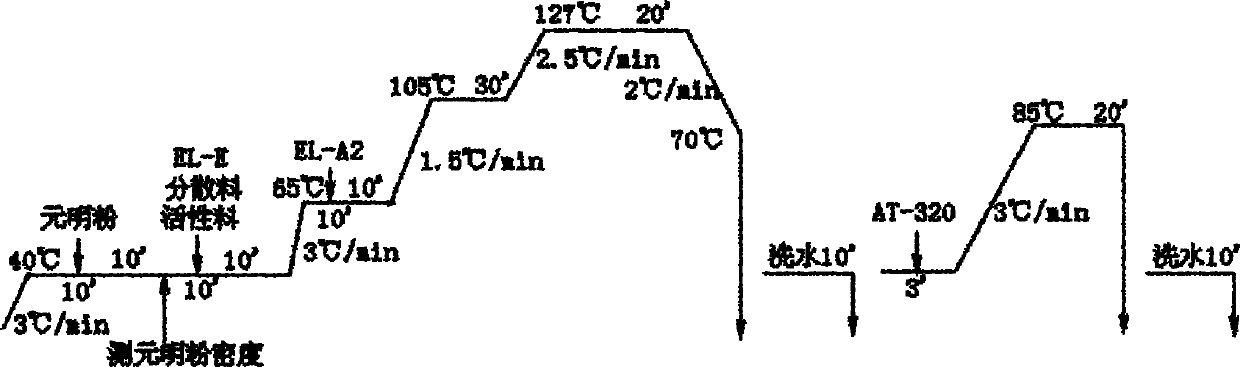

[0025] refer to figure 1 Shown, a kind of dispersive, reactive one-bath dyeing process of polyester-cotton fabric comprises the steps:

[0026] (1) Raise the temperature of the dye solution to 40°C at a rate of 3°C / min, add sodium bicarbonate, feed for 10 minutes, and react for 10 minutes (addition time is not included in this reaction time, and the reaction time that appears below is explained here) ;

[0027] (2) add the reactive dyestuff of fabric weight 3%, the disperse dye of fabric weight 3% and nonionic leveling agent, adjust the concentration of leveling agent in the dye liquor to be 2g / l, add feed 10 minutes, react 10 minutes, wherein, The disperse dyes are T-XD series dyes produced by Zhejiang Yutai Dyeing Technology Co., Ltd., the reactive dyes are C-XD series dyes produced by Zhejiang Yutai Dyeing Technology Co., Ltd., and the leveling agent is used to improve the leveling of disperse and reactive dyes. Dyeability, the present invention adopts the dye enzyme EL-E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap