Method for paving integral energy-saving roof of railroad platform

A laying method and platform technology, applied to roofs, roof coverings, roofs using flat/curved panels, etc., can solve the problems of affecting passengers' rest, inconvenient maintenance and replacement, and high labor intensity, so as to reduce the roof enclosure structure The effect of volume reduction, material and construction cost reduction, and construction cycle shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] Embodiment: the laying method of the present embodiment is as follows:

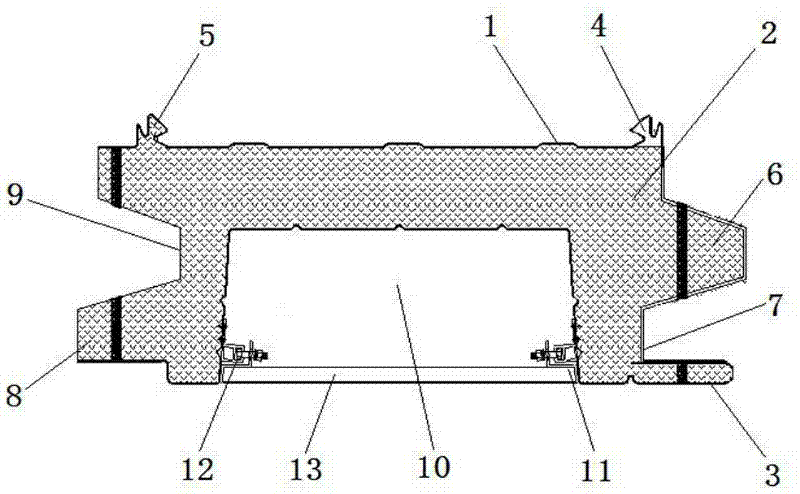

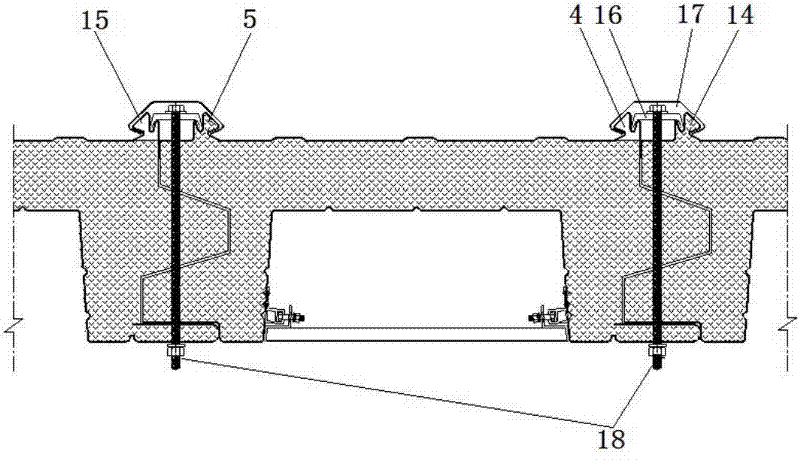

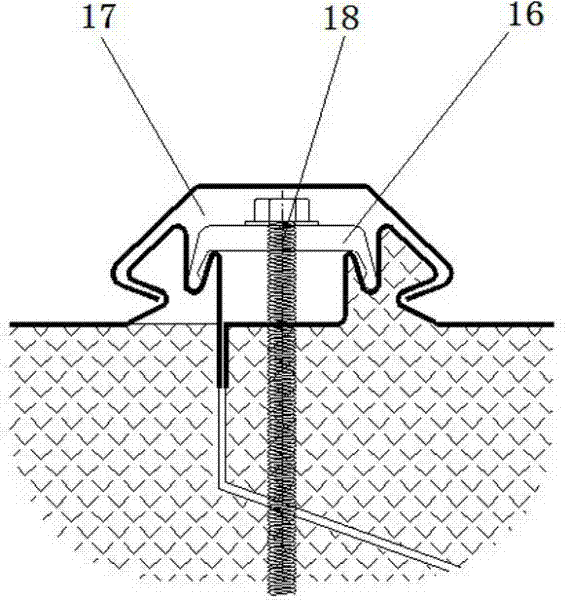

[0029] Firstly, modular design is adopted, and prefabricated Y-shaped columns 19 are distributed at certain intervals on the platform 21. The spacing can be 9 meters or 12 meters, or the spacing of columns can be set according to actual engineering needs. Purlins 20 are welded at nodes and end points of the Y-shaped columns 19, and the purlins 20 connect the Y-shaped columns 19 into one body. Such as figure 2 , 5 As shown in , 6, the roof panels are assembled and fixed sequentially on the purlin 20 along the water direction, and fixedly connected. Finally, the internal electrical equipment and its electrical circuits are installed, the electrical equipment is placed inside the accommodation cavity 10 of the roof panel, and the decorative board 13 is used for final packaging. The components involved in these laying constructions are all designed and manufactured in a standardized manner to achie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com