Automatic modulation and monitoring zonal injection method for water injection well and system thereof

An automatic technology for water injection wells, which is applied to the automatic control system of drilling, measurement, drilling equipment, etc. Adjust the workload and achieve the effect easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

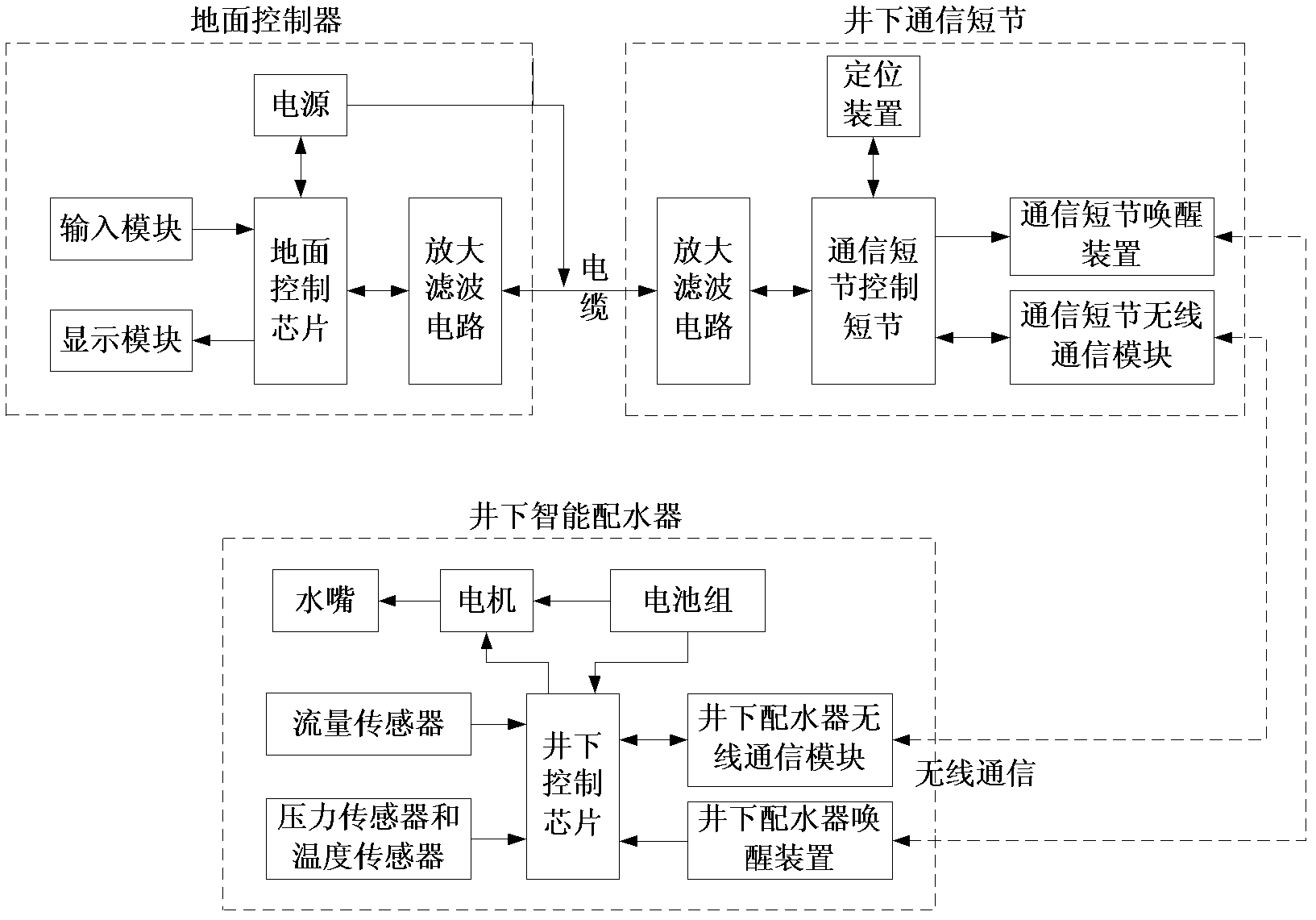

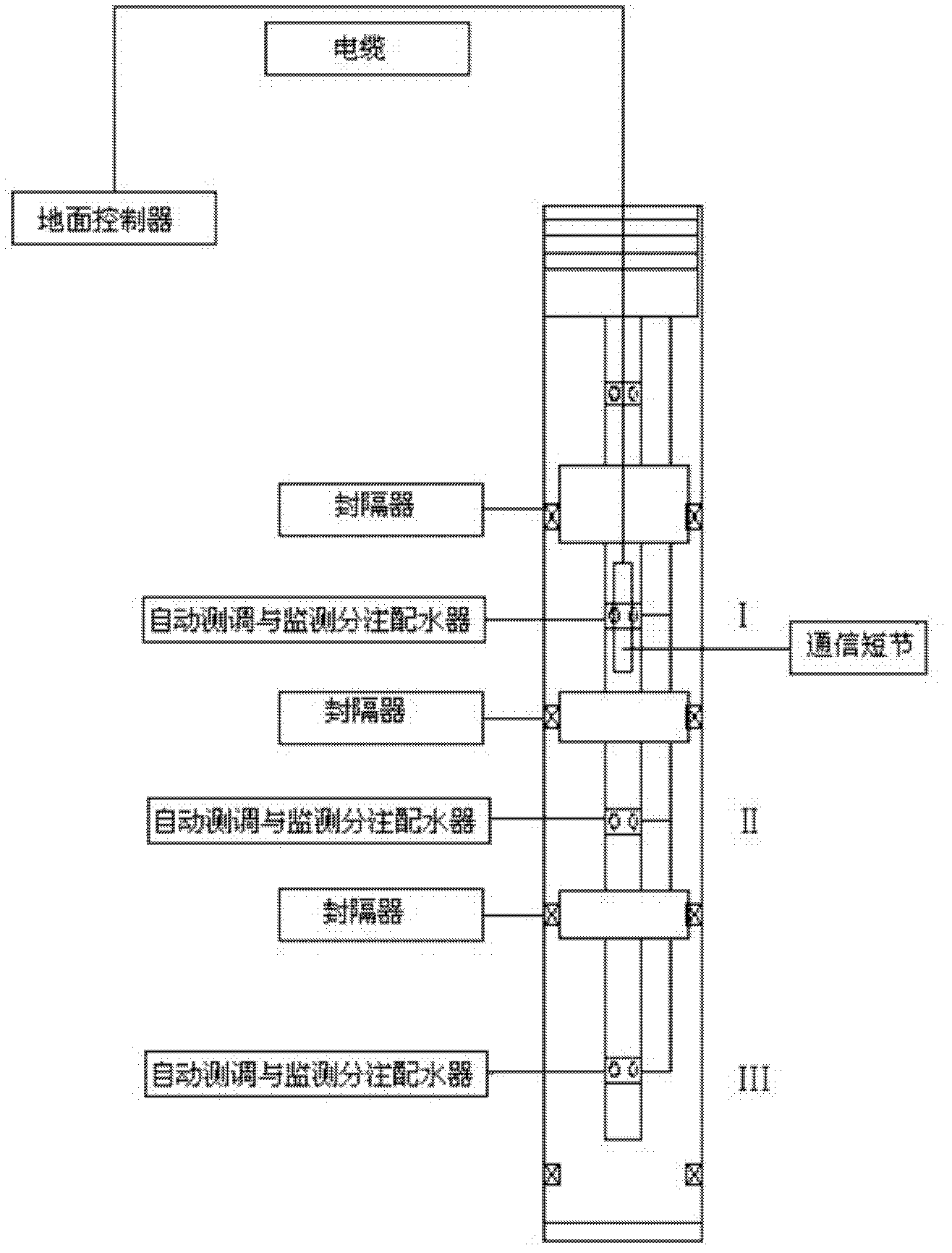

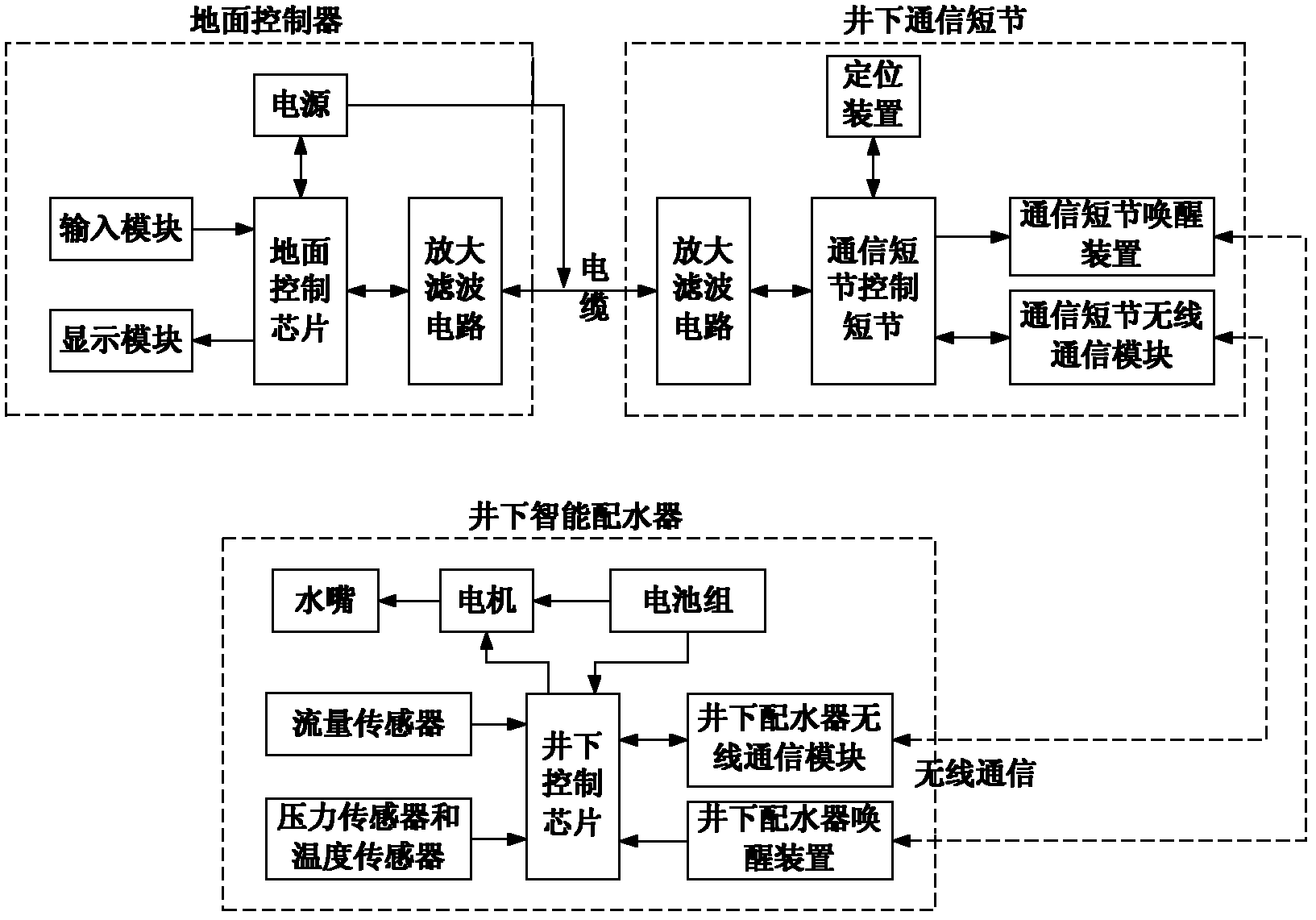

[0030] The invention provides a method for automatic measurement, adjustment and monitoring of water injection wells, the method includes the following steps:

[0031] 1) The ground control system inputs the set flow value to the downhole measuring and adjusting water dispenser;

[0032] On the ground, through the input module of the ground controller, the set flow value of the downhole measurement and distribution water device of each water injection layer is input to the ground control chip, and after being encoded by the ground codec unit of the ground control chip, it is sent to the downhole of the downhole communication nipple control chip The encoding and decoding unit wakes up the downhole water distributor, and sends the set flow value to the motor control unit of each downhole water distributor control chip by means of non-contact communication;

[0033] 2) Collect the actual flow data of the downhole water injection layer; the actual flow data includes the actual flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com