Dynamic evaluation instrument for high-temperature and high-pressure drilling fluid loss

A high temperature and high pressure, drilling fluid technology, used in earth-moving drilling, wellbore/well components, measurement, etc., can solve the problems of small size, single type of fractures, inability to simulate fractures and cavities, and achieve a high degree of automation , record data fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

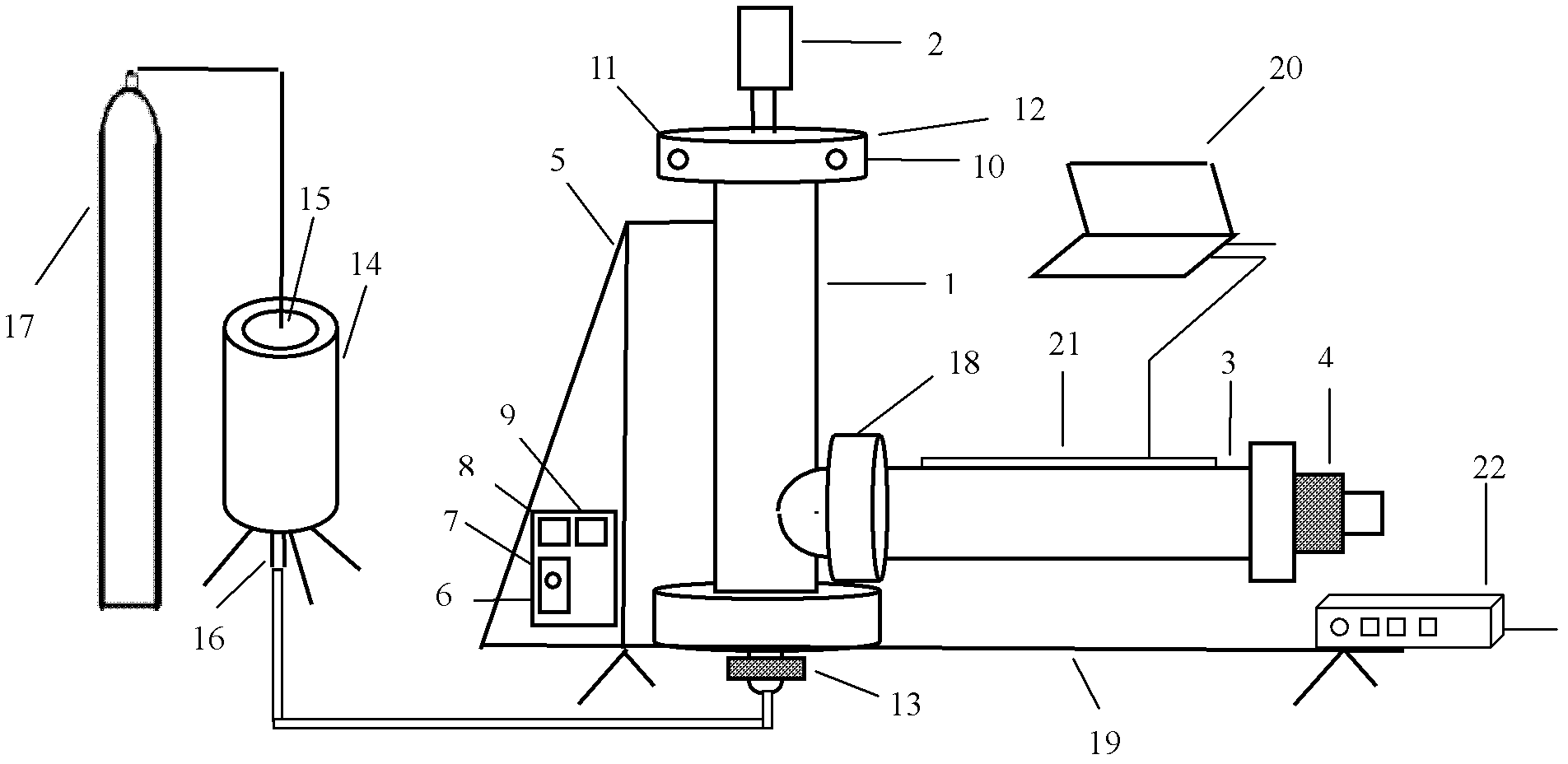

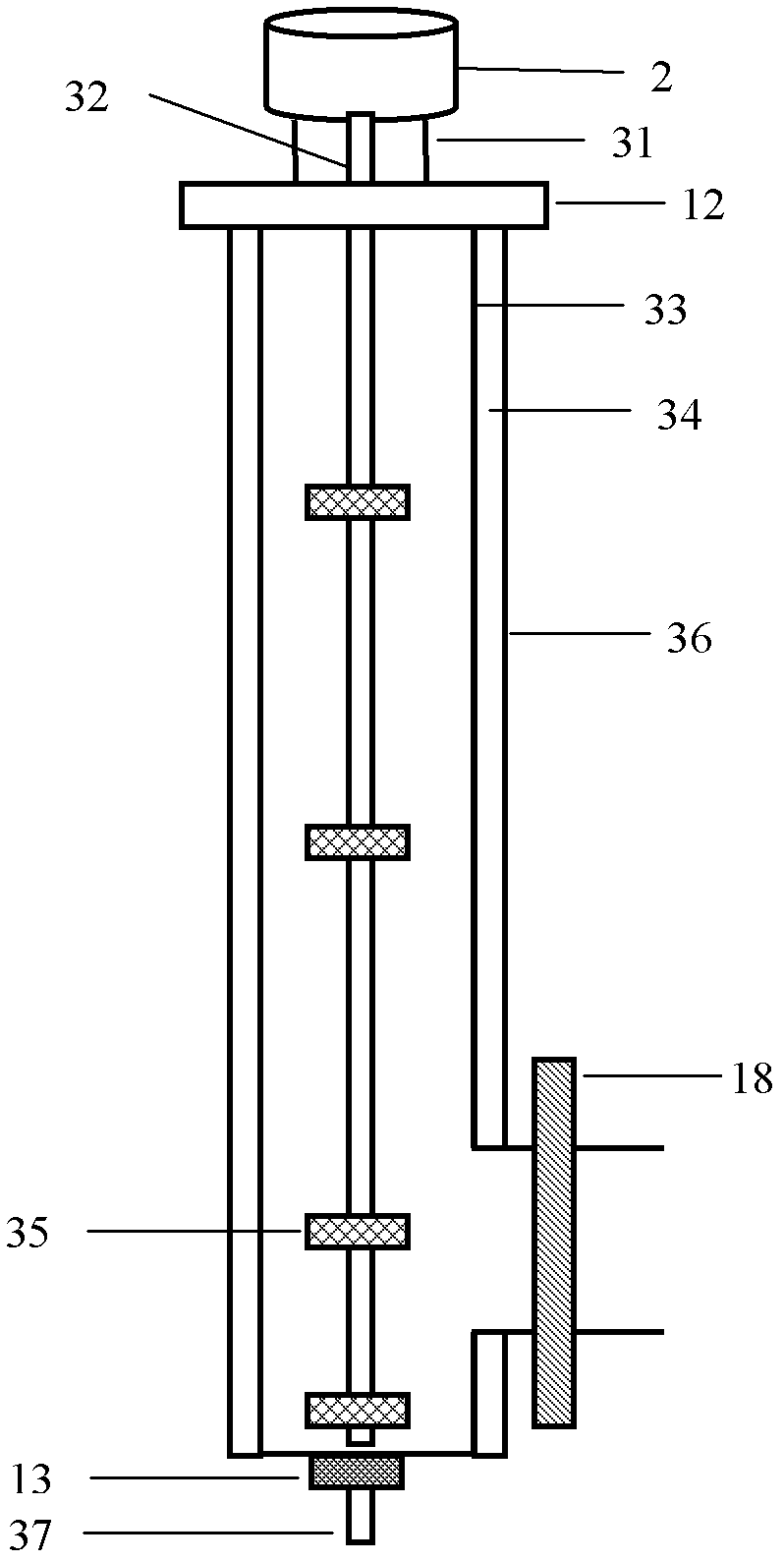

[0022] Further illustrate the present invention according to accompanying drawing below.

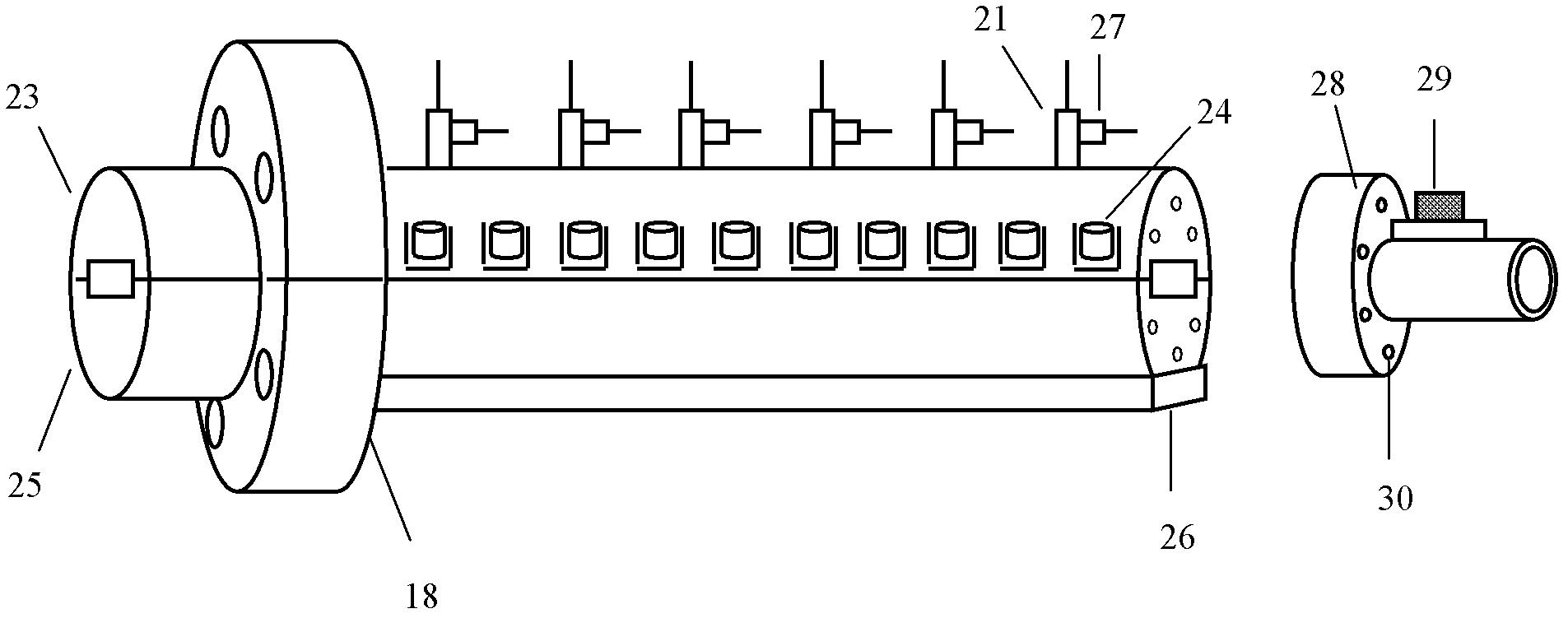

[0023] see figure 1 . The high-temperature and high-pressure drilling fluid loss dynamic evaluation instrument is mainly composed of a circulating kettle body 1, a stirring motor 2, a motor and a temperature control system 6, a fracture module 3, an intermediate container 14, and a nitrogen source 17. The top of the circulating kettle body 1 There are vent holes 10 and air inlet holes 11 on the cover 12. The stirring motor 2 is fixed on the top cover of the kettle body and is sealed and connected with the circulating kettle body. There is a kettle body drain valve 13 at the bottom of the circulating kettle body 1. The air inlet 15 of the intermediate container 14 is connected to the nitrogen source 17, and the drain hole 16 of the intermediate container 14 is connected to the tank drain valve 13; the lower part of the circulating tank 1 and the crack module 3 fixed on the base 19 pass t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com