Device for underground detecting sand production of oil well

A technology for downhole detection and oil wells, applied in wellbore/well components, measurement, earthwork drilling and other directions, can solve the problems of oil and gas layer sand burial, formation and wellbore channeling, and surface manifold sand accumulation, etc. Easy to operate and simple to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

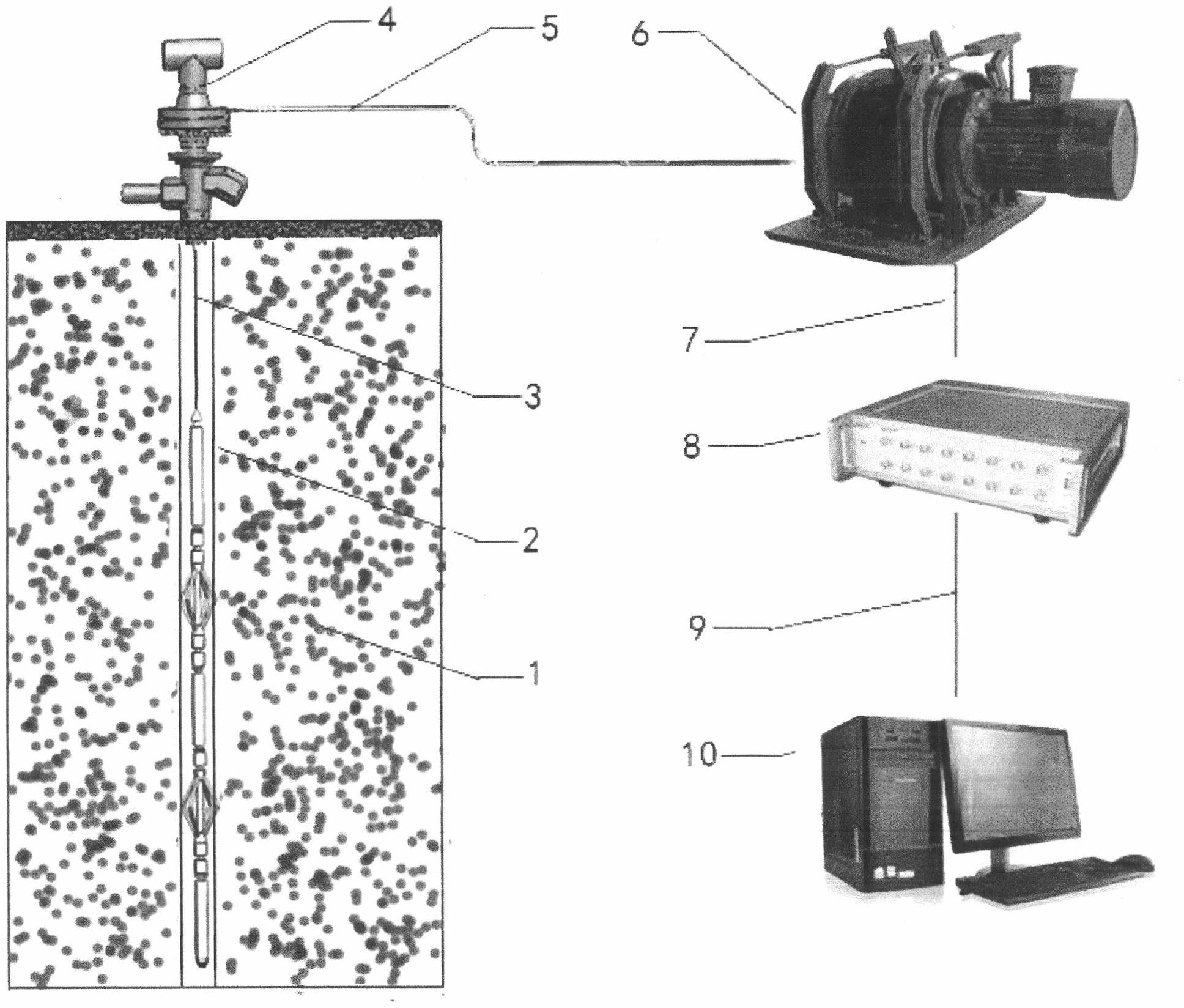

[0016] refer to figure 1 , figure 2 , a device for downhole detection of sand production in oil wells, comprising a downhole detector 2, a drawworks 6, an optical fiber grating demodulator 8, and a computer 10, which are connected with transmission cables 3, 5, 7, and 9,

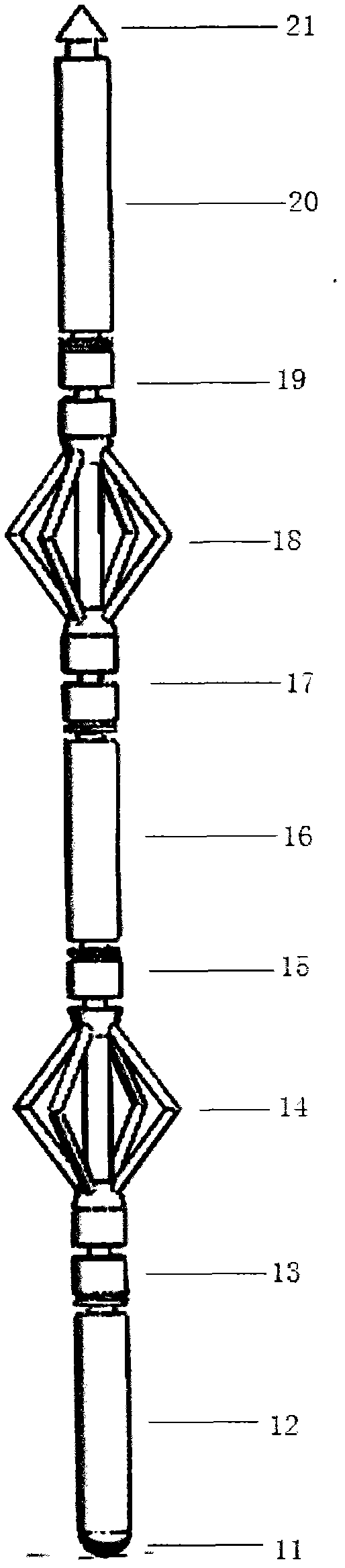

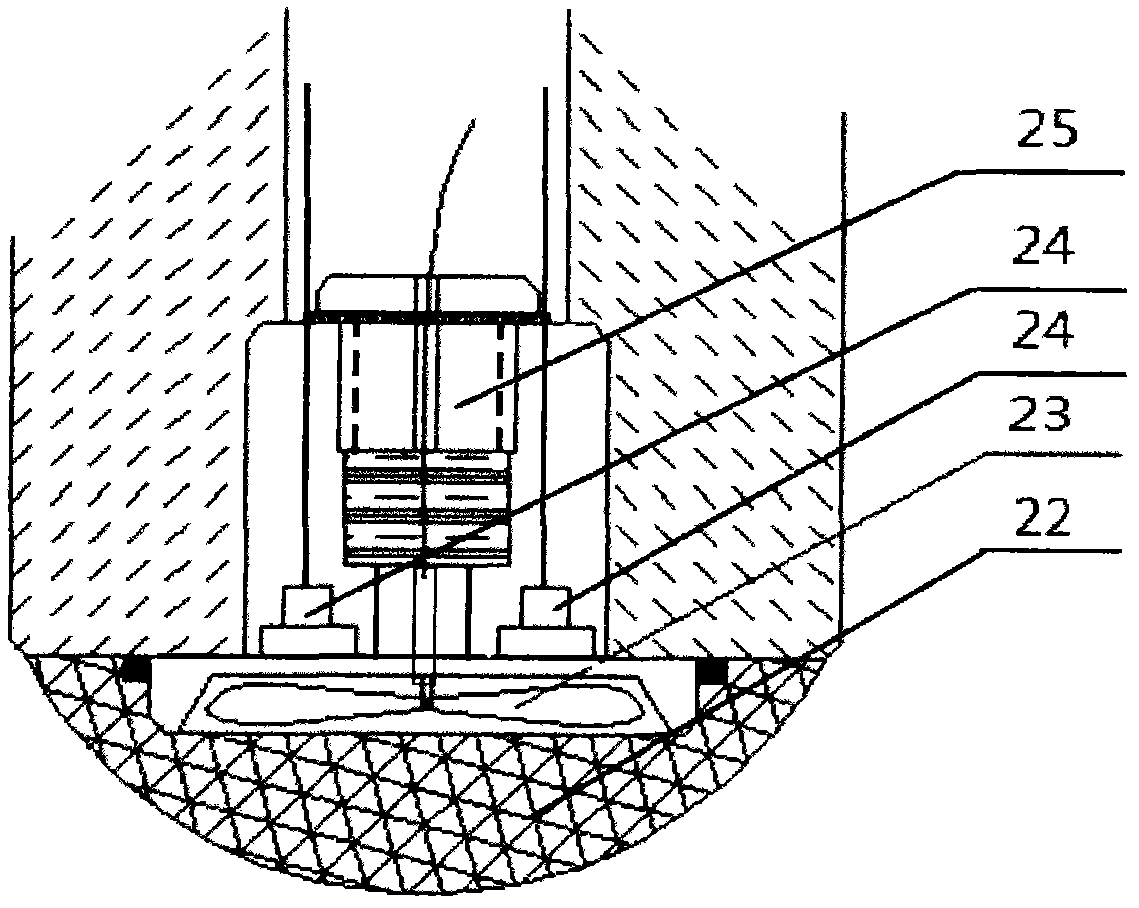

[0017] The detector 2 is located in the wellbore 1, the bottom of which is connected to the measuring sub-joint 12, and the metal mesh guide head 11 is installed under the measuring sub-joint 12, and the fiber grating acceleration and ultrasonic sensors are installed in the measuring sub-joint 12 every 90°. Load blocks 16, 20 are installed on the measuring short joint 12, an optical cable head 21 is arranged on the load block 20, a centralizer 14 is arranged between the measuring short joint 12 and the load block 16, and the load block 16 and the load block Centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com