Vertical wind power aluminium alloy fan blade system

An aluminum alloy and fan blade technology, which is applied in the field of wind power generation, can solve the problems that the fan blade installation structure does not form a wind release and refraction guide channel, the overall strength is low, and the fan blade weight is large, so as to improve the strength and performance of the fan blade. High wind utilization rate and small wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

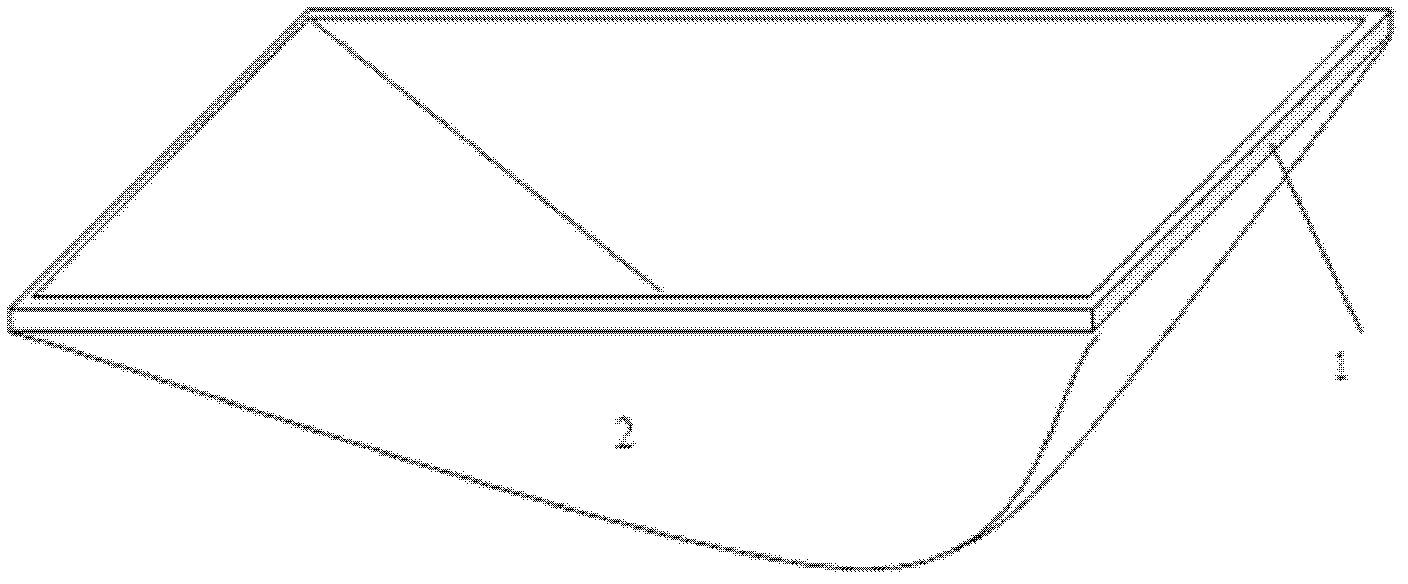

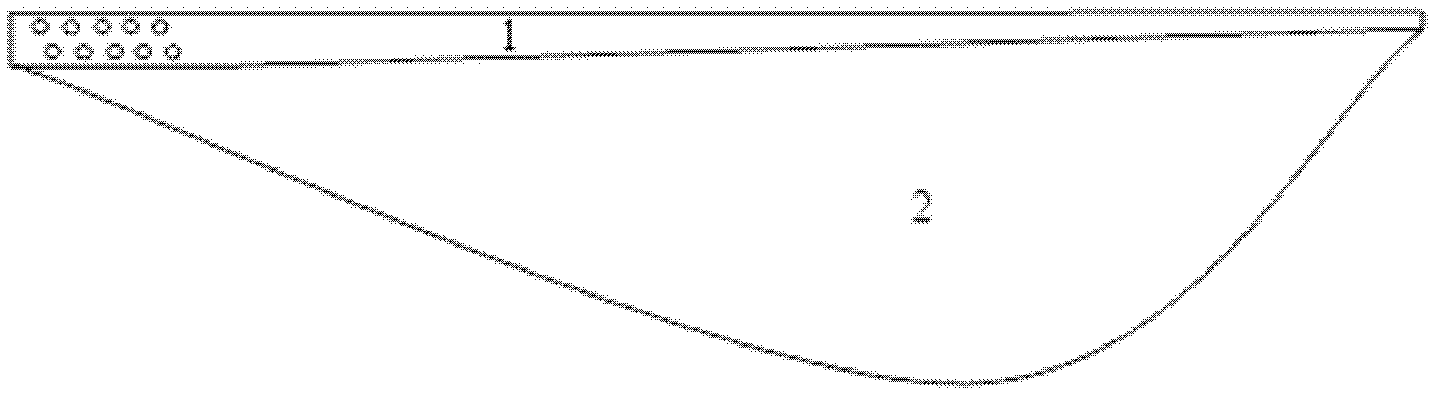

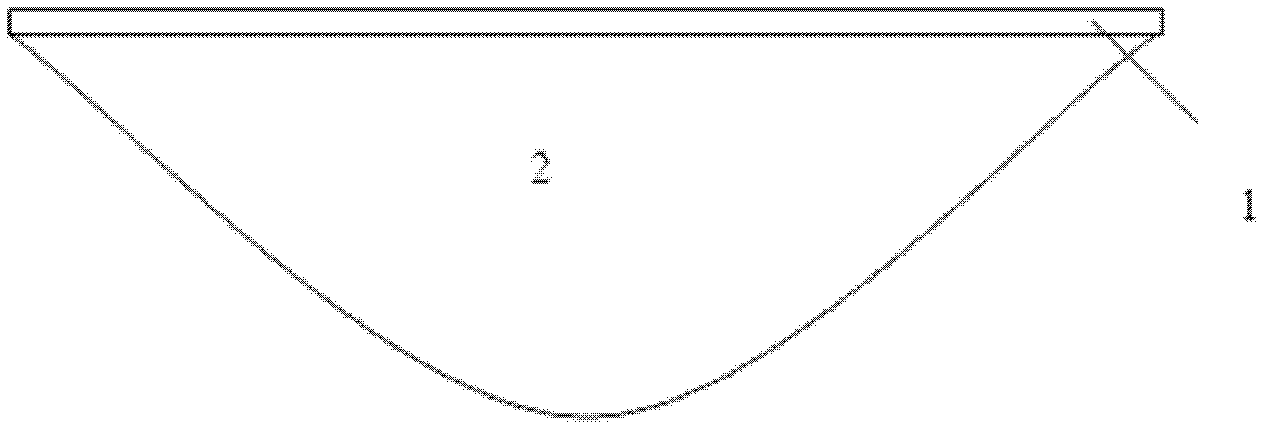

[0028] Specific implementation mode one: combine Figure 1 to Figure 11 To illustrate this embodiment, the vertical wind power aluminum alloy fan blade system in this embodiment includes N blades, a shaft 3, an upper flange 4 and a lower flange 8, and the vertical wind power aluminum alloy fan blade system also includes 2N 1 fixed connecting piece 5, 2N reinforced triangular plates 6 and 2N supporting pieces 7, each fan blade includes fan blade frame 1 and fan blade body 2, fan blade frame 1 and fan blade body 2 are integrally pressed and stretched by aluminum alloy Formed to form the fan blade, the longitudinal section of the fan blade body 2 is a wing streamline shape, the cross section of the fan blade body 2 is a protruding curved surface, and the upper flange 4 and the lower flange 8 are installed on the shaft from top to bottom. 3, N fan blades are in an annular array around the machine shaft 3, and the upper and lower ends of two adjacent fan blades are respectively con...

specific Embodiment approach 2

[0034] Specific implementation mode two: combination Figure 1 to Figure 3 To illustrate this embodiment, the fan blade frame 1 of this embodiment adopts a C-shaped aluminum alloy frame member, or adopts an aluminum alloy square tube or two right-angled triangular aluminum alloy tubular sections to make a rectangular frame body. Such setting reduces the weight of the fan blade and increases the strength of the fan blade. It is mainly used as a support carrier for the blade body of the fan blade. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0035] Specific implementation mode three: combination Figure 4 with Figure 5 This embodiment will be described. The number of blades in this embodiment is three. In this way, the angles of the three blades are 120 degrees apart, and the three blades complement each other to generate a balanced rotational moment, the best dynamic balance characteristics, and stable rotation. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com