Undamped hydraulic yaw system based on pressure detection and control method of undamped hydraulic yaw system

A yaw system, no damping technology, applied in the control of wind turbines, wind turbines, wind power generation and other directions, can solve the problems of increasing friction and wear at the brake caliper, high power waste, unit vibration and wind rotor blade fatigue, etc. Reduce friction and wear, avoid power waste, and improve damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to facilitate the understanding of the specific principle and control method of the present invention, detailed embodiments of the system are described in detail through the accompanying drawings.

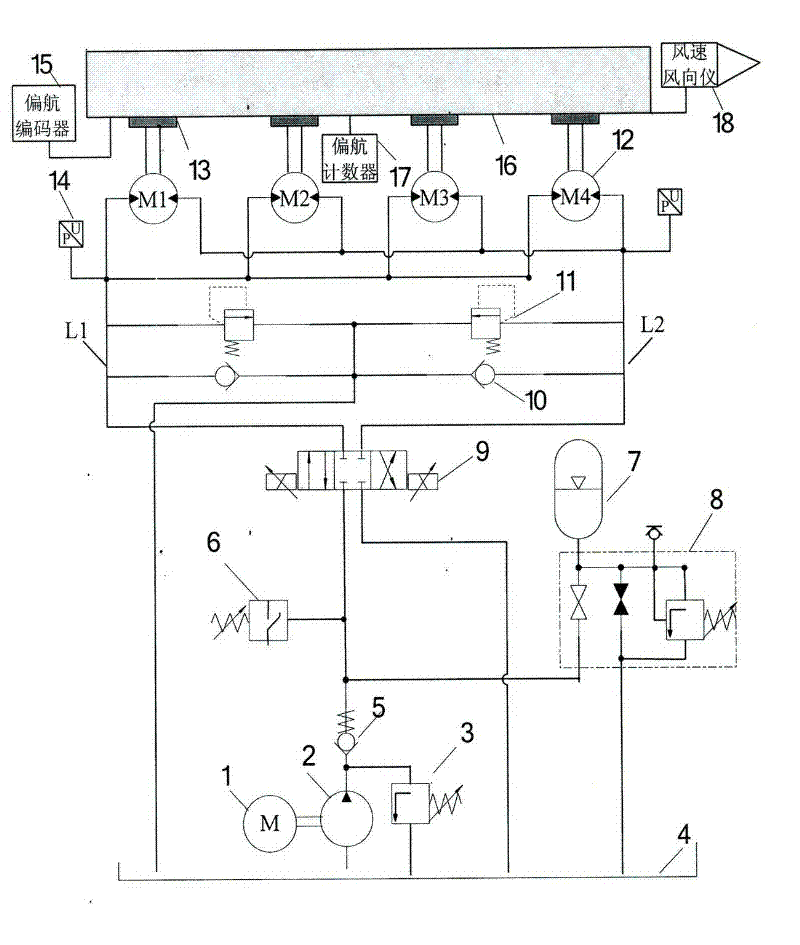

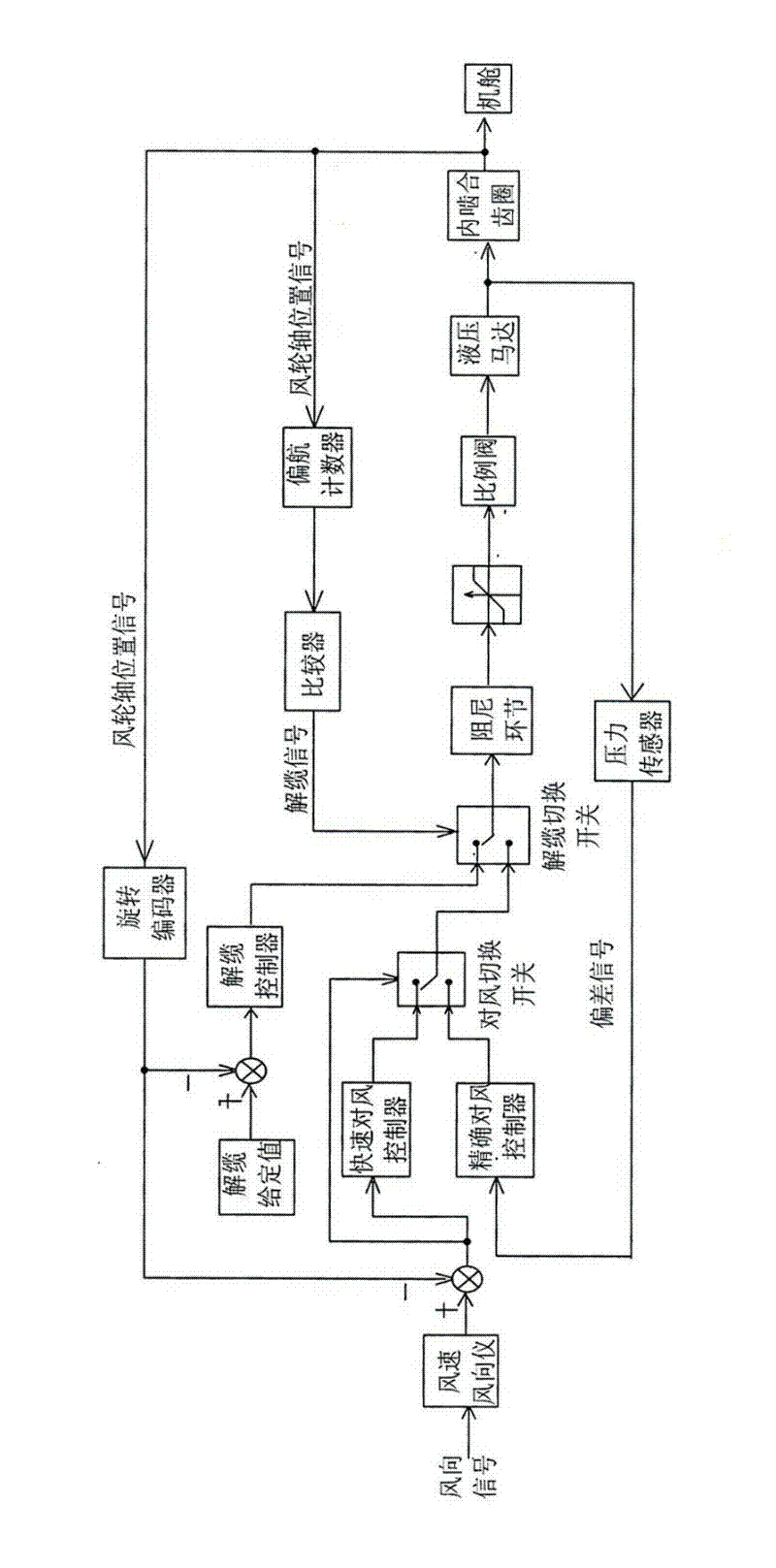

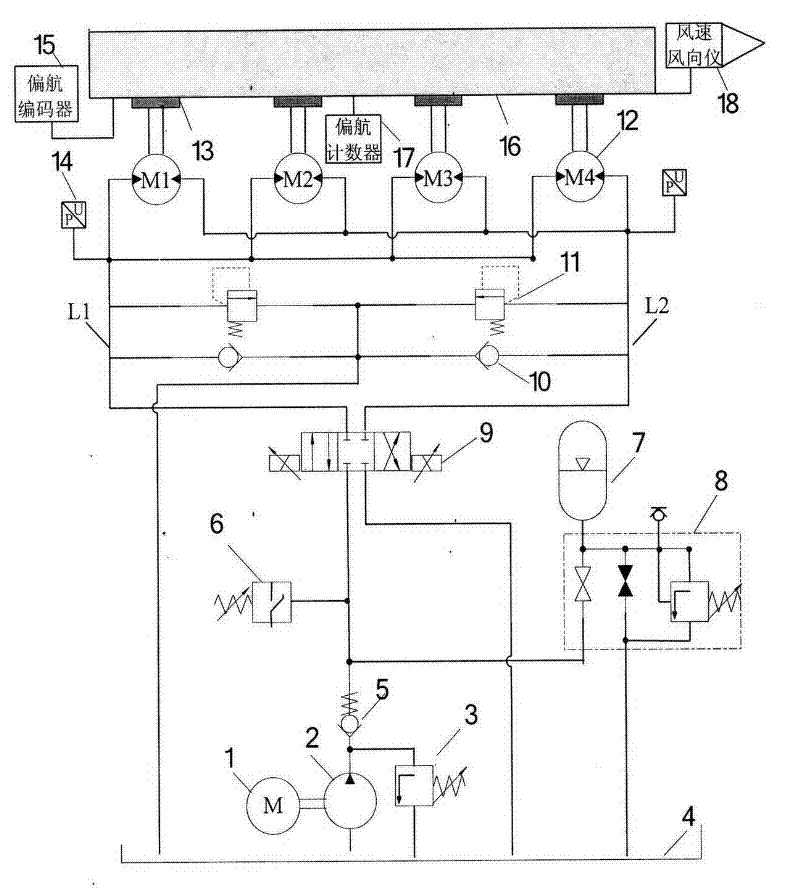

[0027] Such as figure 1 As shown, motor 1, oil pump 2, relief valve 3, oil tank 4, check valve 5, pressure relay 6, accumulator 7, accumulator safety valve group 8, proportional reversing valve 9, check valve 10, Relief valve 11, low-speed high-torque hydraulic motor 12, yaw gear 13, pressure sensor 14, yaw encoder 15, meshing ring gear 16 in the nacelle, yaw counter 17, wind speed and direction instrument 18 and connected to the oil pump and the Oil pipes L1, L2 between hydraulic motors.

[0028] The motor 1 drives the oil pump 2 to rotate to supply oil to the hydraulic yaw system; the outlet of the oil pump 2 is sequentially connected to one end of the overflow valve 3, the check valve 5, the accumulator 7, the pressure relay 6 and the proportional reversing valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com