Plunger typed master cylinder

A plunger type and piston technology, which is applied in the field of plunger type master cylinders, can solve the problems of difficult assembly process of piston and spring components, rising product cost, and increased weight, so as to eliminate difficulty, shorten assembly process, and reduce overall weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Hereinafter, the embodiments of the present invention will be described in detail with reference to the attached illustrative drawings. Such embodiments are just an example. Since those skilled in the art of the present invention can implement them in various forms, it is not limited to Examples described here.

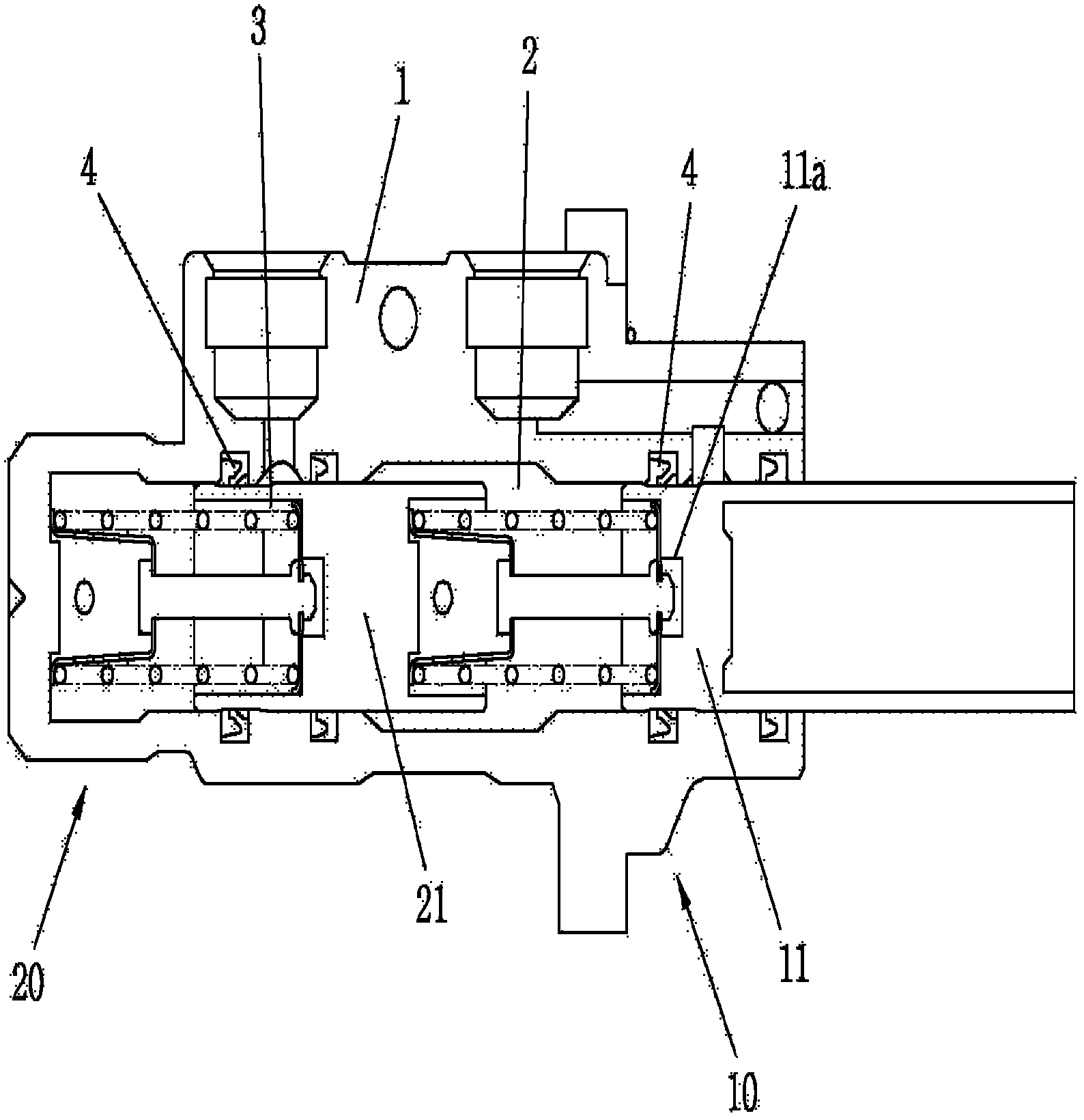

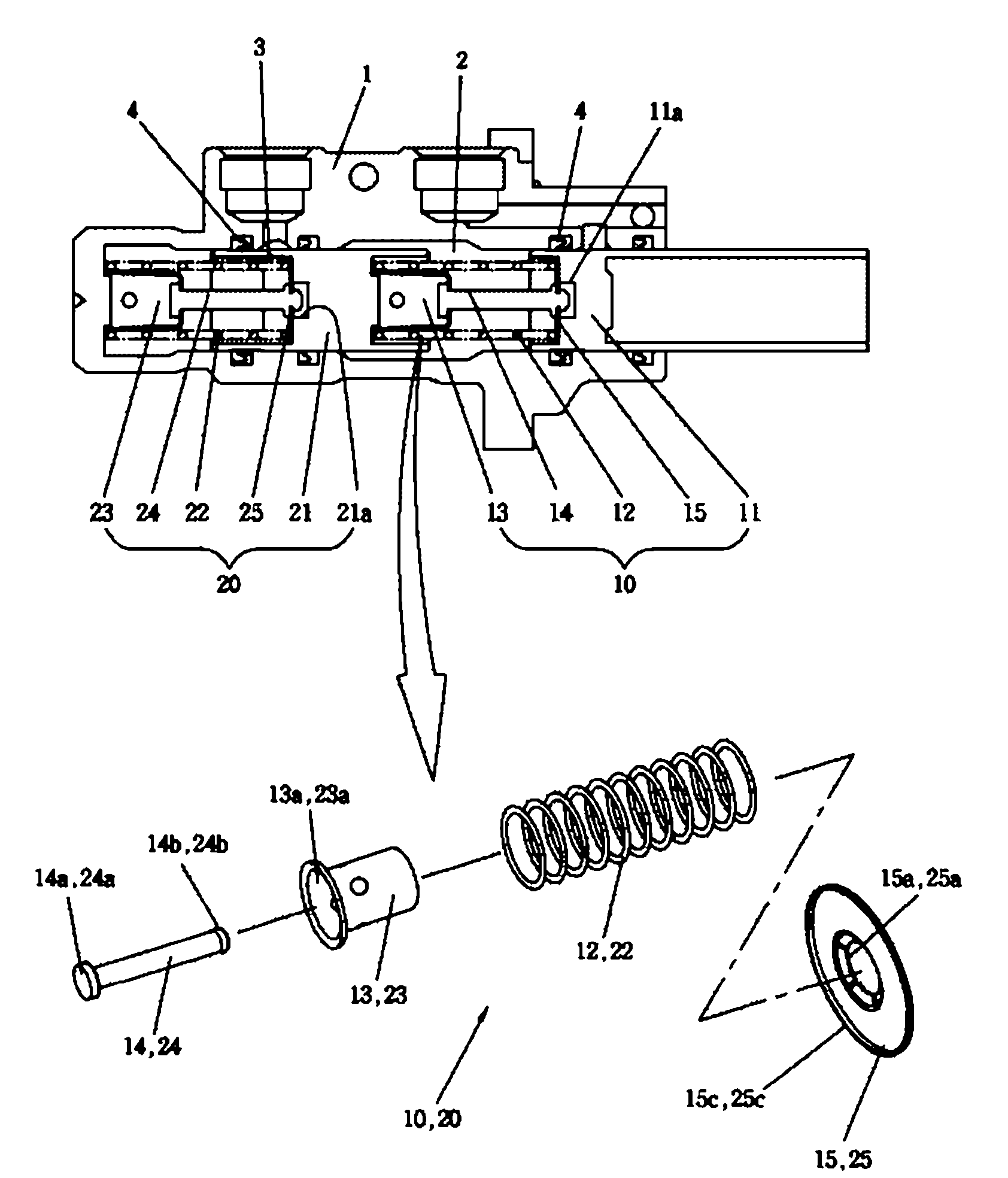

[0053] figure 1 The structure of the plunger-type master cylinder with a spring assembly according to this embodiment is shown.

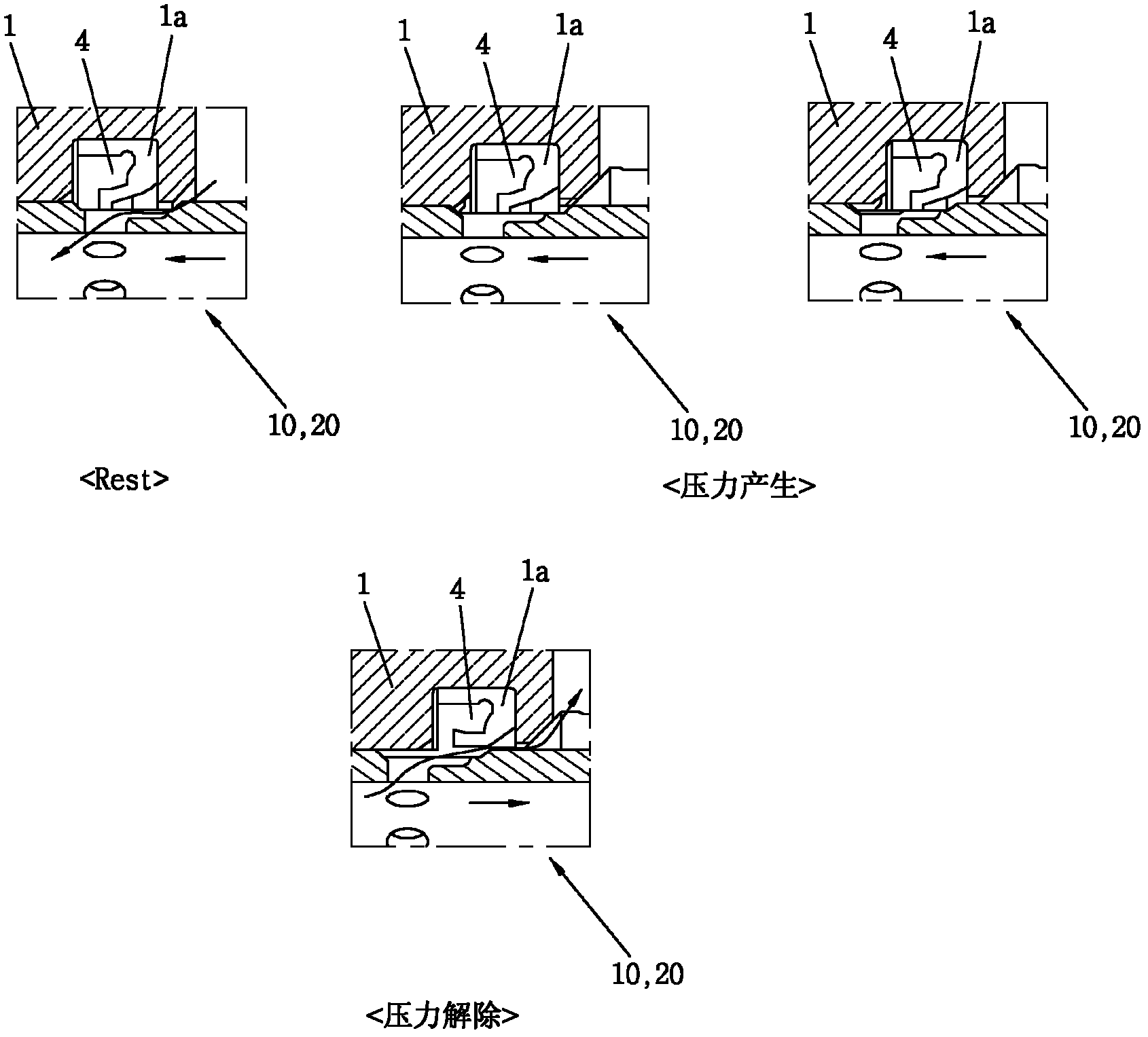

[0054] As shown in the figure, the plunger-type master cylinder 1 is composed of: a cylinder block forming a pair of chambers, a main chamber 2 and a floating chamber 3; The main piston 10 of force; the floating piston 20 accommodated in the above-mentioned floating chamber 3; and the cup-shaped oil seal inserted into the cup-shaped oil groove 1a formed on the inner wall surface of the above-mentioned main chamber 2 and floating chamber 3 respectively to form the flow of brake fluid (Seal Cup)4.

[0055] The cup-shaped oil seal 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com