Special fire view door of garbage incinerator

A technology for waste incinerators and fire gates, which is applied in the direction of incinerators, combustion methods, and combustion types, and can solve the problems of urgent development and use of new fire gates, energy waste of old-fashioned fire gates, and lax closure of gaps, etc. Achieve the effect of benefiting workshop production, preventing heat conduction, and reducing erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

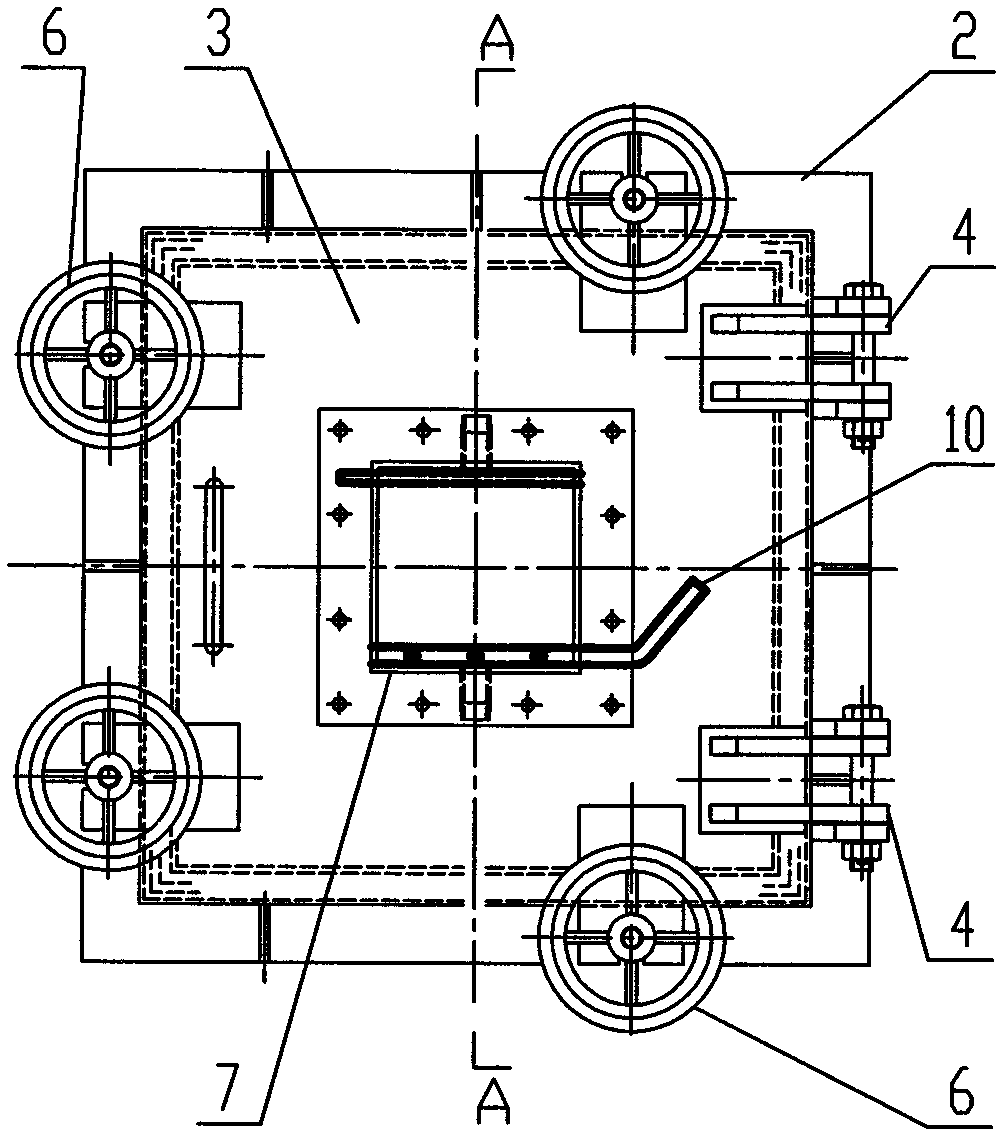

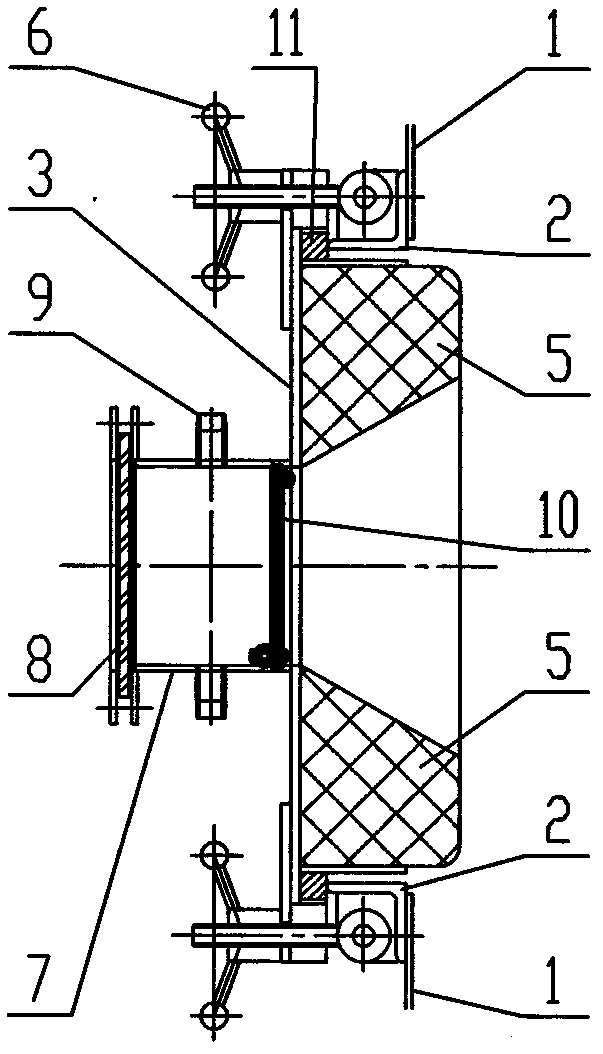

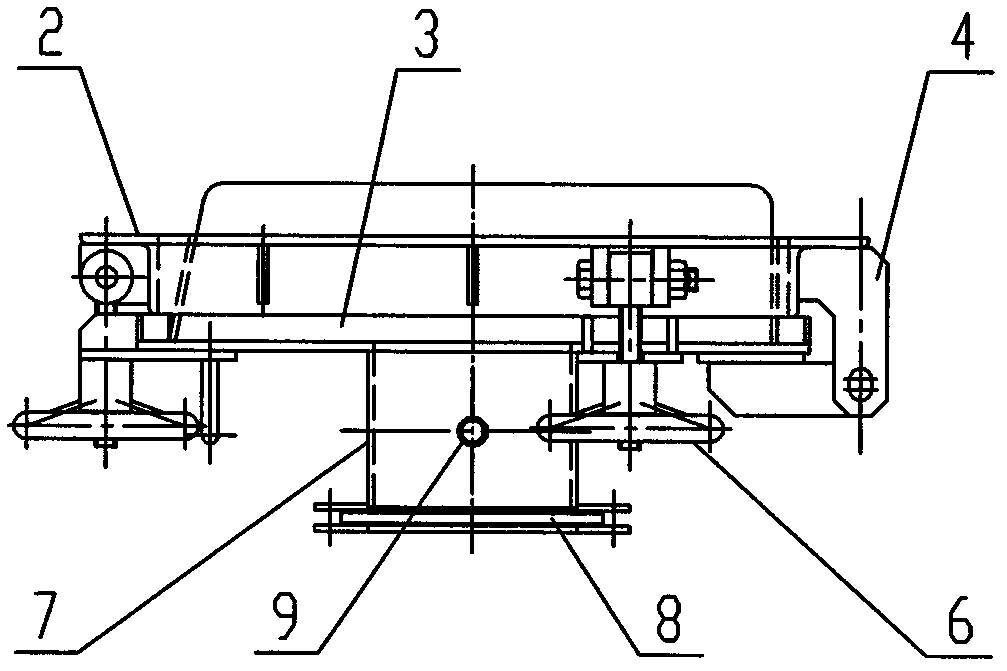

[0011] Depend on figure 1 , figure 2 and image 3 It can be seen that the special fire door for garbage incinerators of the present invention includes a door frame 2 connected to the furnace body 1, the door body 3 is connected with the door frame 2 through a hinge 4, the door body 3 is provided with a refractory concrete heat insulation layer 5, and the edge of the door body 3 is provided with Locking mechanism 6, door body 3 is also provided with see burner tube 7, sees burner tube 7 and installs high temperature resistant glass door 8 on the observation port of burner tube 7, sees the side of burner tube 7 and is provided with air blowing inlet 9, sees burner tube 7 and The joint of the door body 3 is provided with a manually flipped smoke blocking door 10, and an asbestos rope 11 is provided between the door frame 2 and the door body 3.

[0012] The fire inspection door of the invention is applicable to various types of domestic waste and medical waste incinerators and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap