Humidifying air heating furnace

A technology of heater and hot air outlet, applied in air humidification systems, heating methods, air heaters, etc., can solve the problem of unresolved drying of chicken houses, inability to transmit coal-fired energy, heat transfer and heat exchange Slow speed and other problems, to achieve the effect of low noise, small heat loss and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

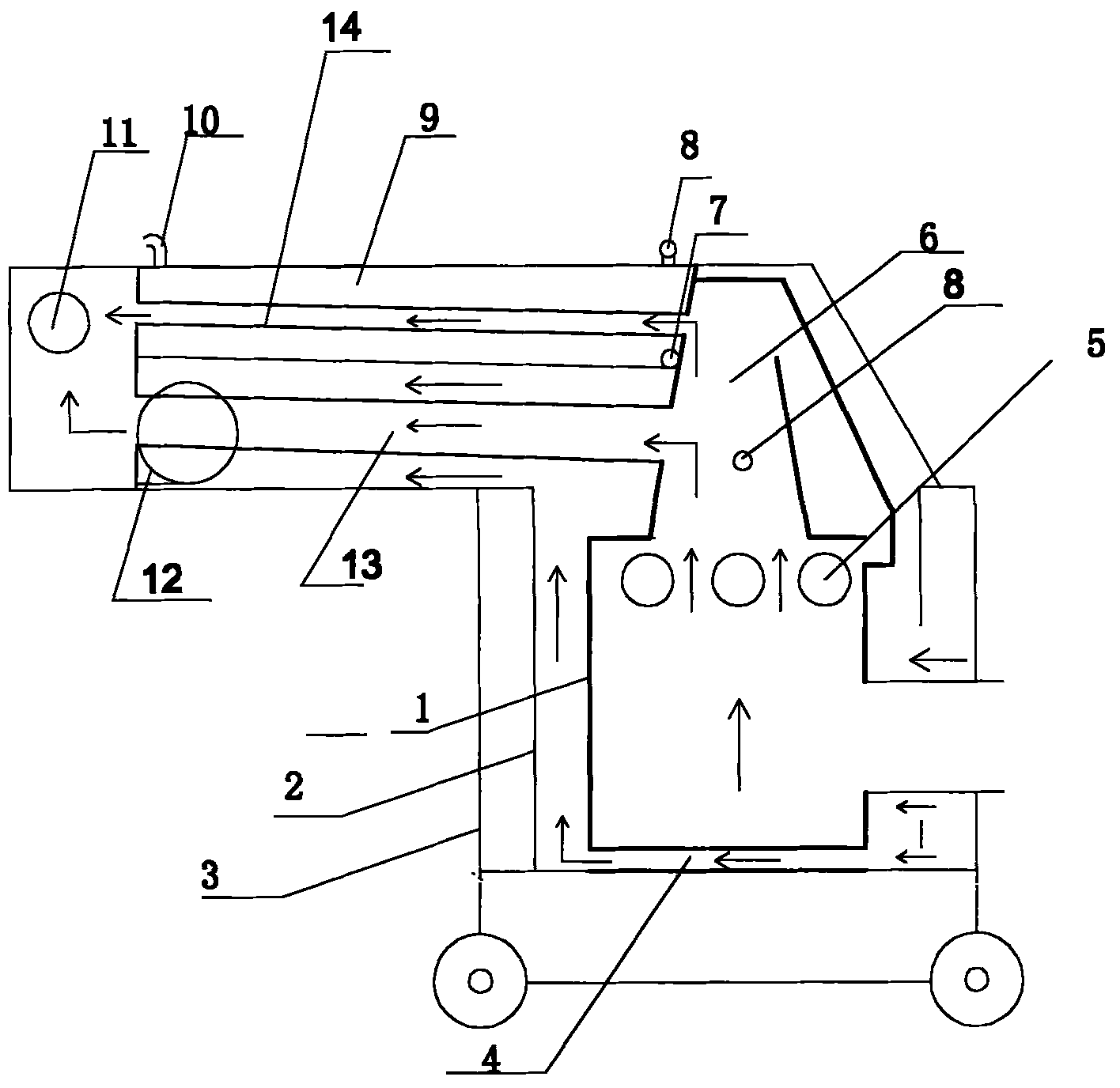

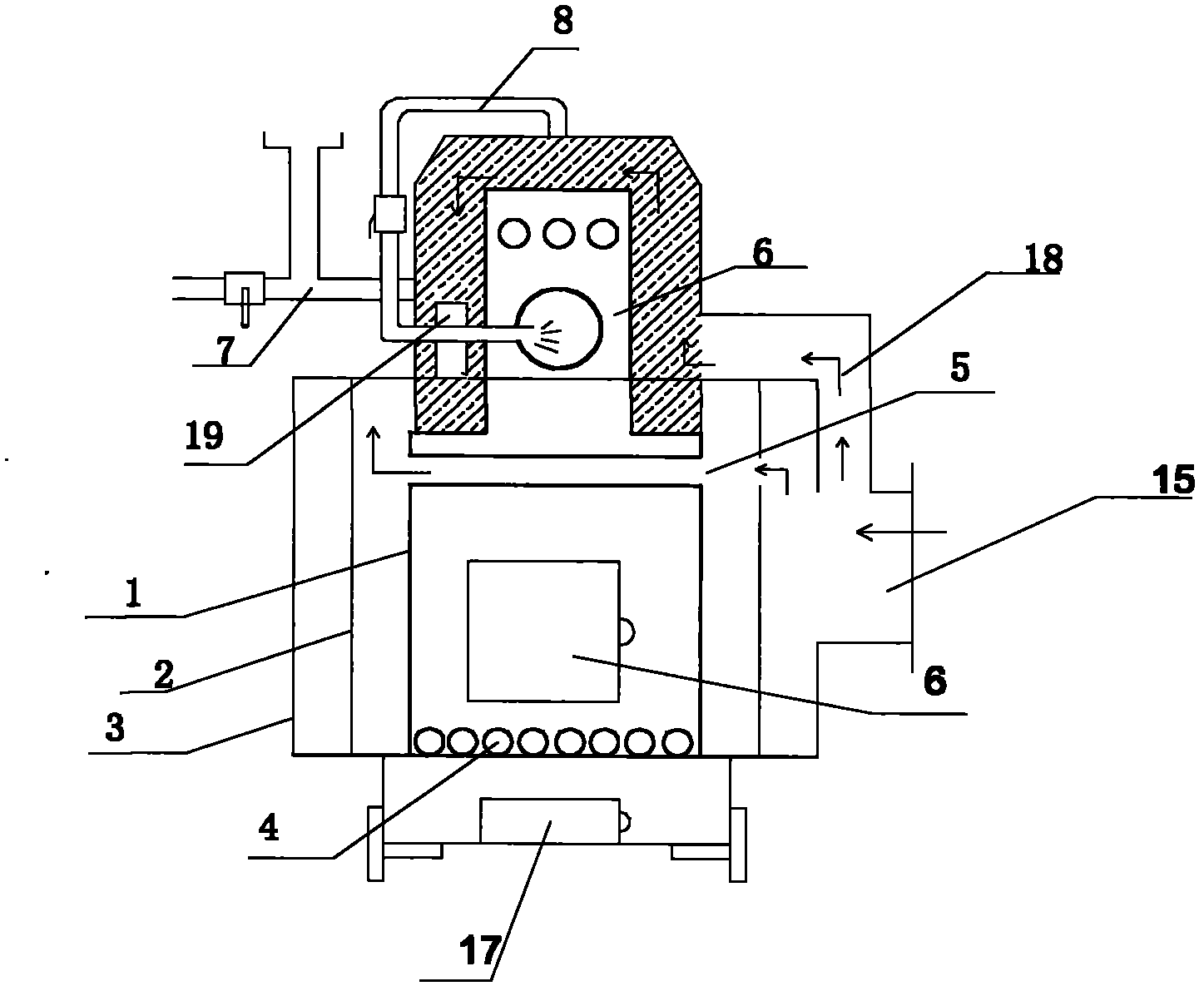

[0026] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

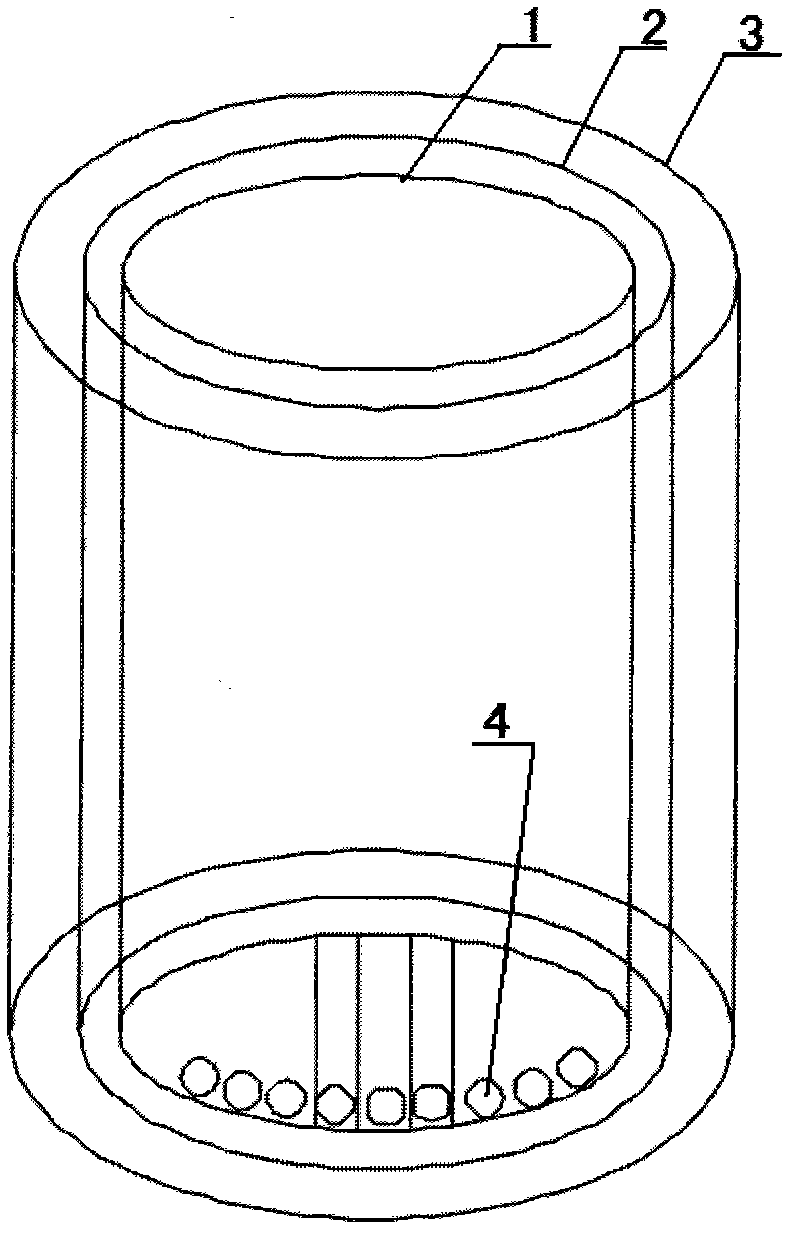

[0027] see figure 1 , 2 , 3, a kind of humidification warm air stove, comprises a furnace inner liner 1, the inner liner 1 is provided with the middle liner liner 2, the middle liner liner 2 is provided with the outer liner liner 3, and the lower part of the liner liner 1 is provided with ventilation Malleable steel grate 4, the upper part is provided with malleable steel heat dissipation pipe 5, and a secondary combustion chamber 6 is provided above the inner tank 1, and a combustion-supporting steam nozzle 8 is provided in the secondary combustion chamber 6, and a water tank is provided on the left side of the secondary combustion chamber 6 9 and the hot air outlet 12, the water tank 9 is provided with a water inlet 7, the auxiliary humidification port 10 inside the house, the water tank 9 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com