Refrigerant compressor

A technology of compressors and refrigerants, applied in compressors, refrigerators, refrigeration components, etc., can solve the problems of large parts space, high cost, wear, etc., and achieve the effects of space requirements and cost reduction, sound reduction, and strong support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

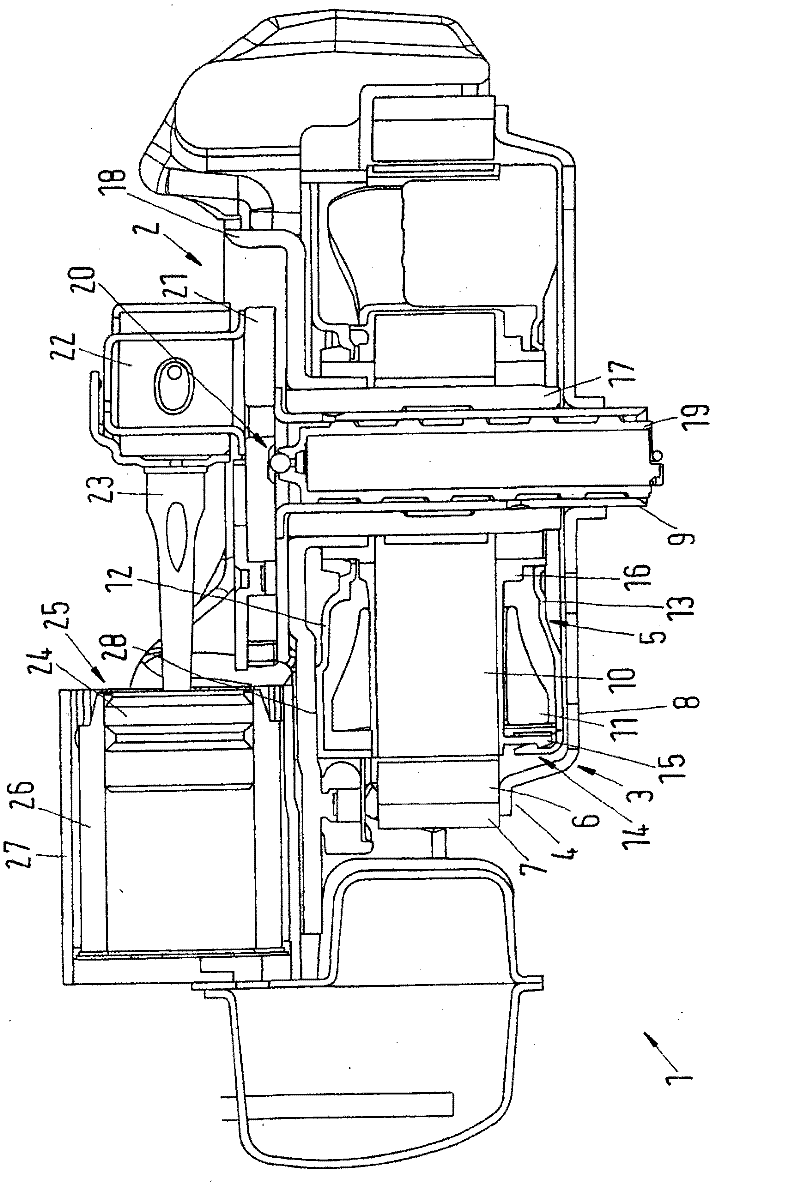

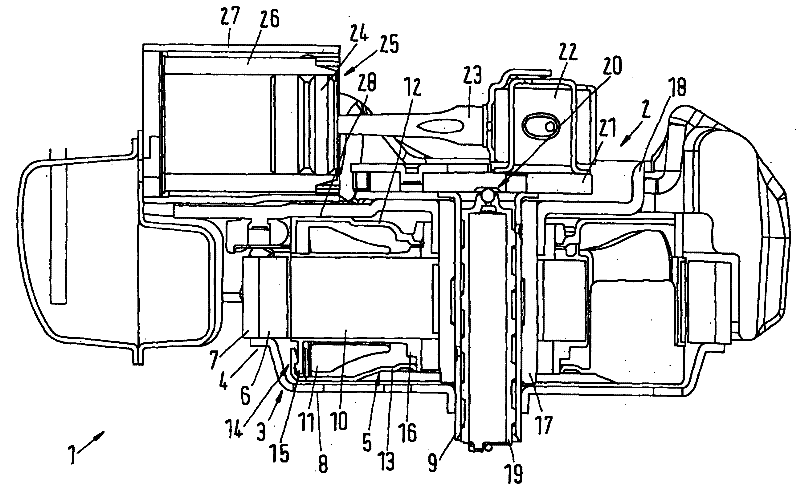

[0025] figure 1 is a schematic sectional view of the refrigerant compressor 1 . The refrigerant compressor 1 includes a compressor assembly 2 and an electric motor 3 , the electric motor 3 is an external rotor type electric motor, and the electric motor has an external rotor 4 and an internal stator 5 . The rotor 4 comprises permanent magnets 6 surrounded radially by short rings 7 . The rotor 4 is connected non-rotatably to a shaft 9 via a plate-shaped base 8 . The lower end of the shaft 9 is immersed in an oil pool not shown.

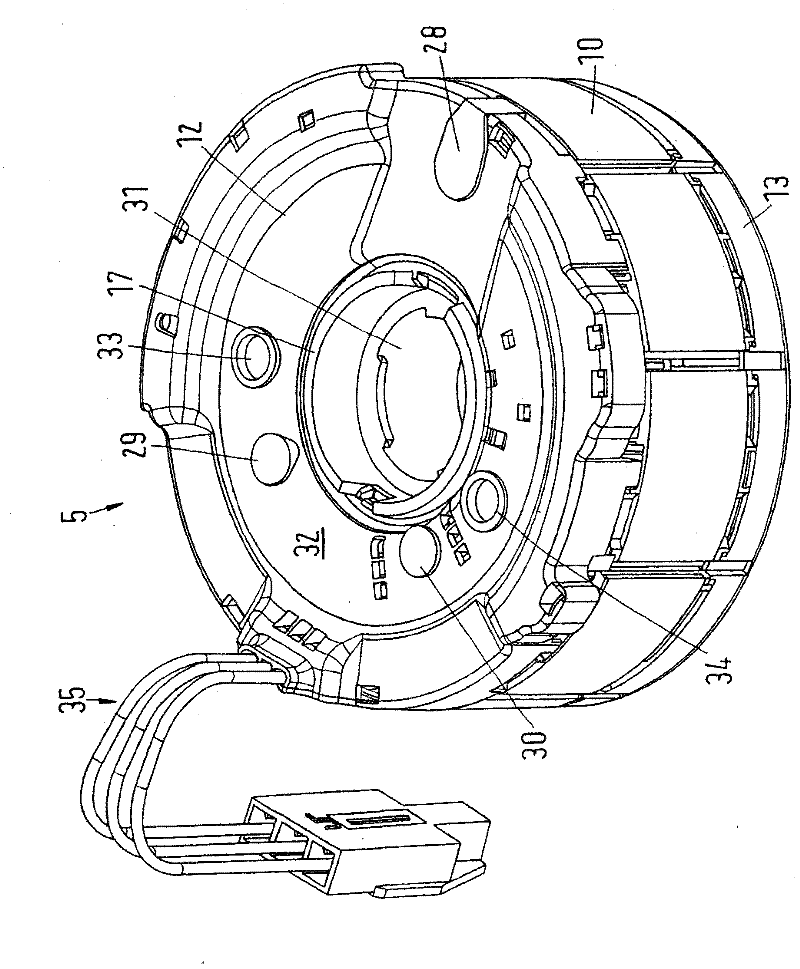

[0026] An annular air gap is formed between the rotor 4 and the stator 5 . The stator 5 comprises a stator lamination 10 and a winding 11 . Furthermore, the stator 5 includes an upper cover plate 12 and a lower cover plate 13 . The cover plates 12 , 13 include radially inwardly directed projections 14 which engage with correspondingly formed parts 15 of the protruding housing 16 of the stator lamination 10 .

[0027] The shaft 9 is supported radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com