Electrically-controlled firework discharging box

A gun case, electronic control technology, used in fireworks, offensive equipment, weapon types, etc., can solve problems such as chaos, complexity, high cost, and serious problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

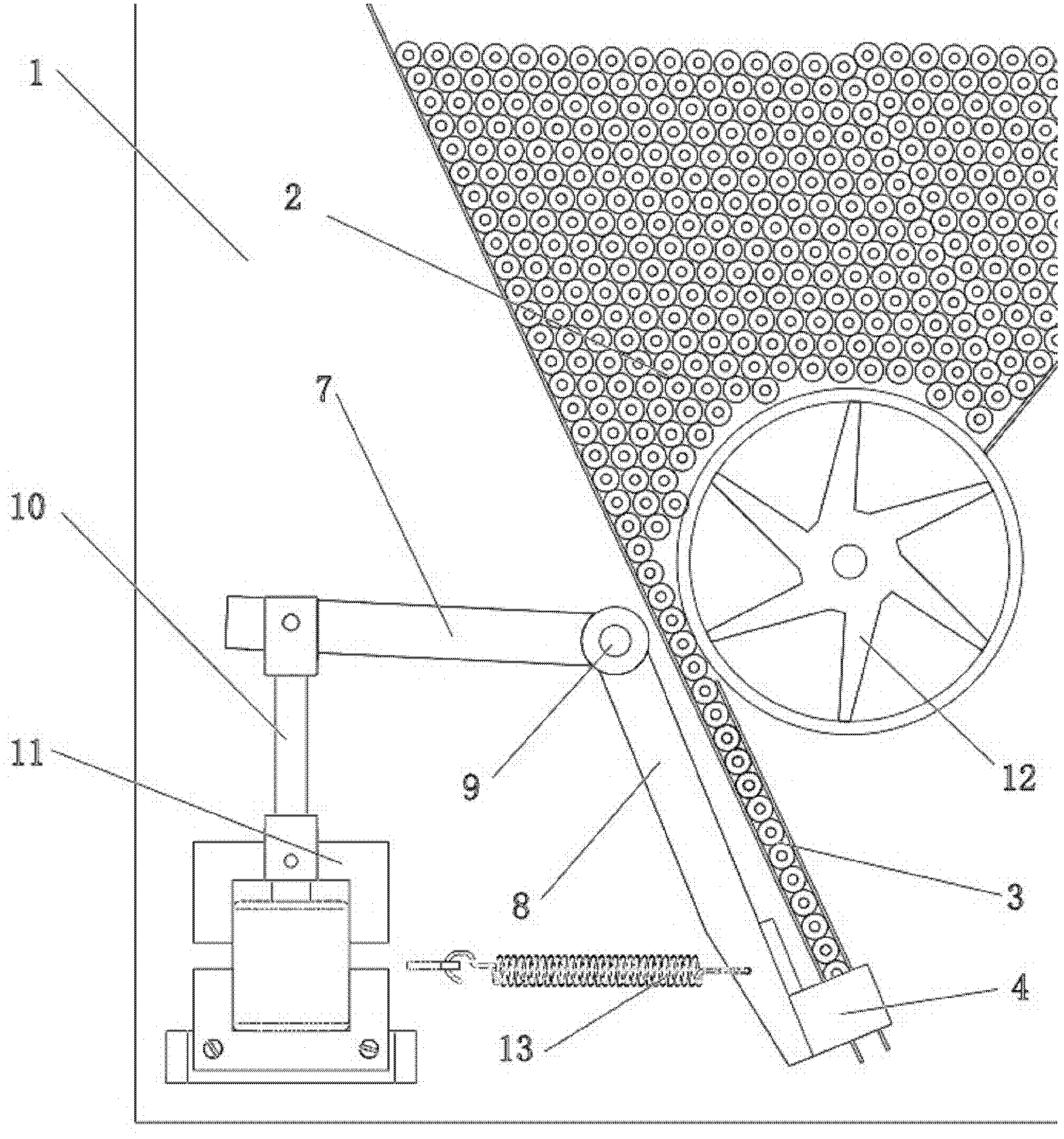

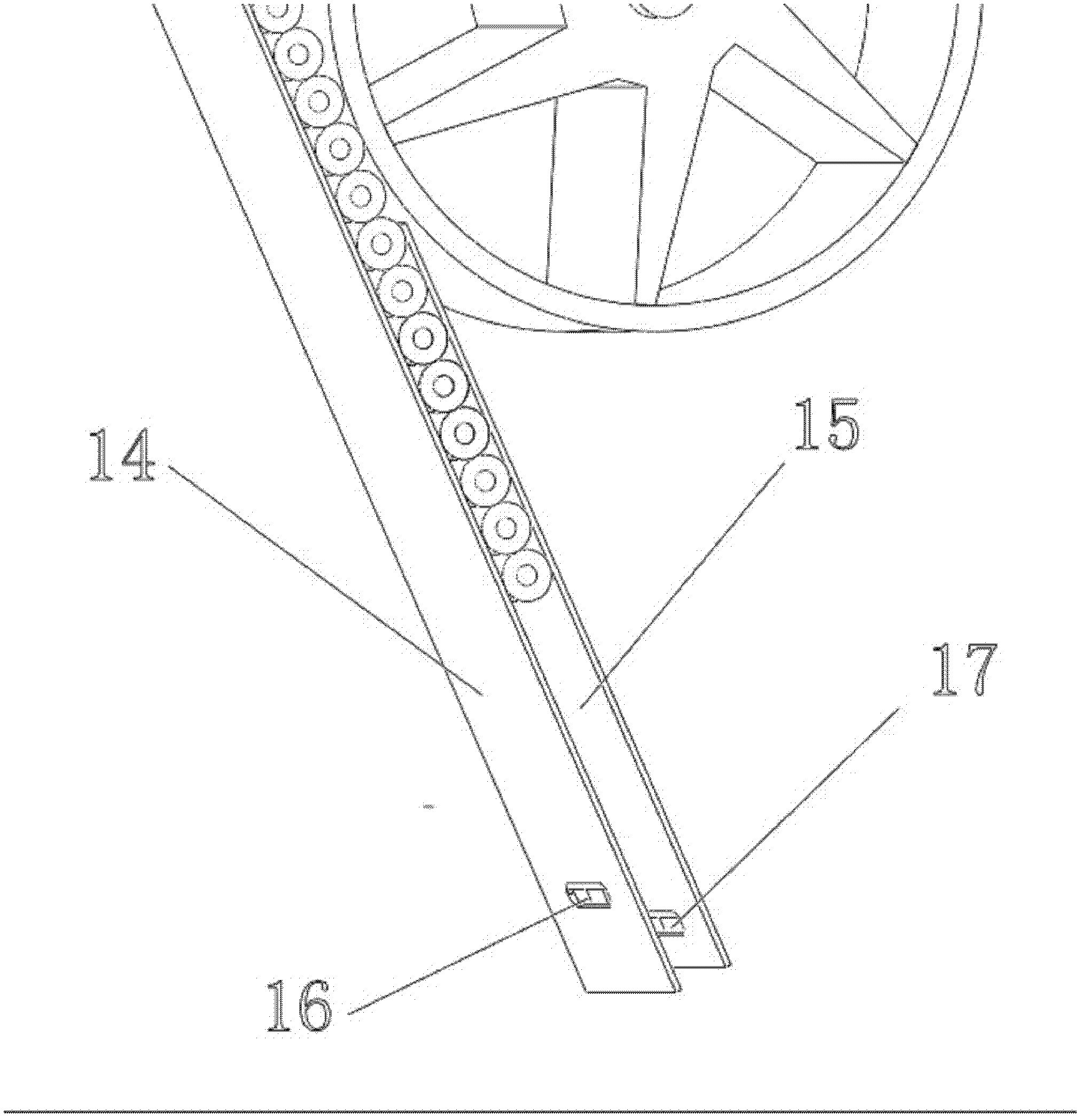

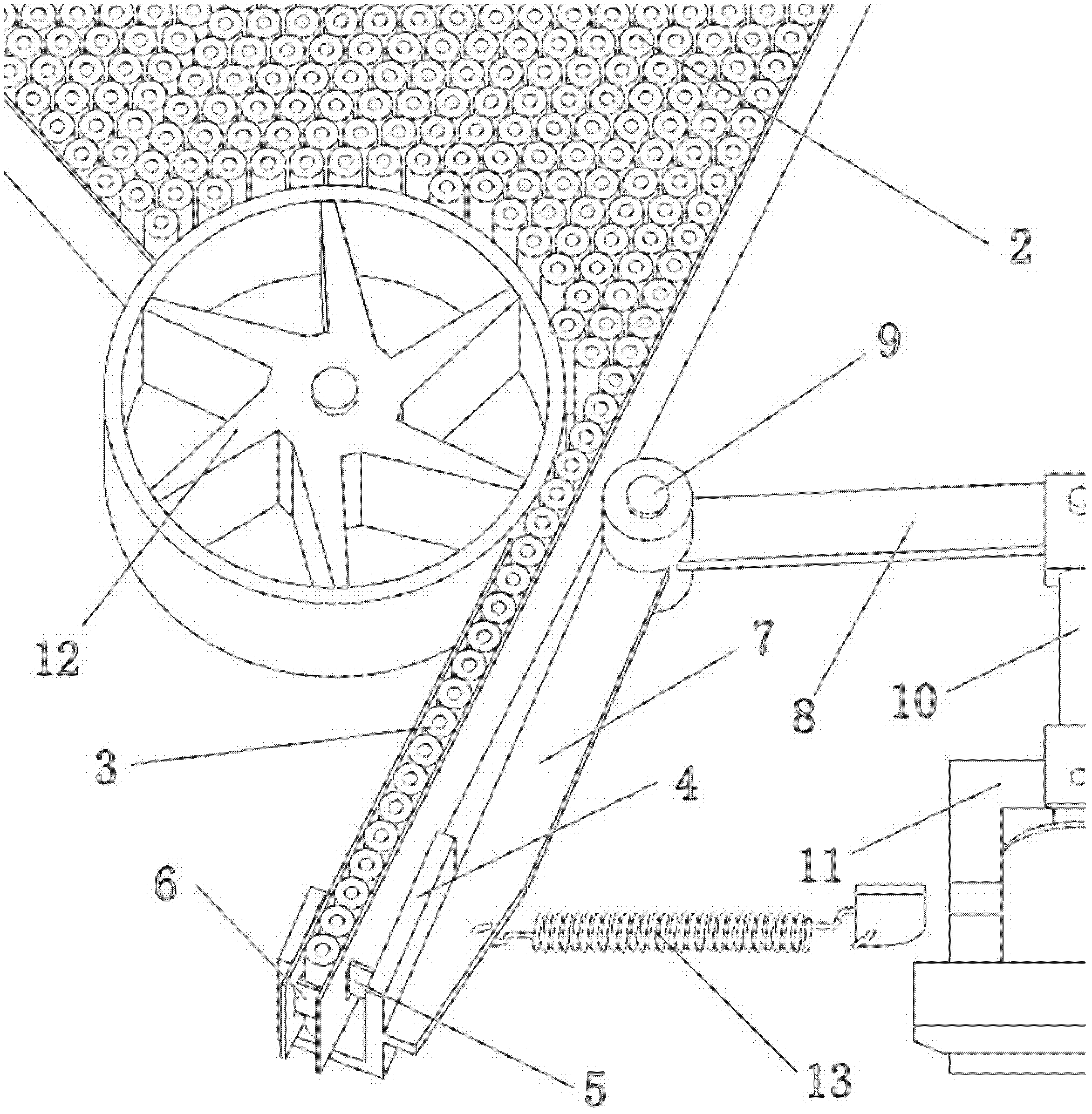

[0009] Compared with the existing cannon box, this cannon box is upgraded from the mechanical drive of others to its own electromagnetic drive. In order to reduce mechanical wear and tear, the upper gun door 5 and the lower gun door 6 are installed on the door frame 4 instead of being installed on the existing guide rail, and the door frame 4 is fixed on the driving arm 8 and installed at the outlet end of the gun channel 3 . The driving arm 8 and the power arm 7 are fixedly connected together and hinged on the bottom plate 1 through the hinge shaft 9 . In this way, the synchronous swing of the door frame 4, the upper gun door 5 and the lower gun door 6 can be driven by the swing of the power arm 7 and the driving arm 8, thereby realizing the opening and closing of the gun path. figure 1 shown. In this process, since there is no linear sliding of the guide rail, the mechanical wear is greatly reduced. figure 1 shown. The left track plate 14 has an upper door hole 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com