Plane structured light and light pen-based precise three-dimensional measurement method for complex part

A three-dimensional measurement and component technology, applied in the field of precision measurement, can solve the problems of only distance measurement, difficult processing, low precision, etc., and achieve the effect of easy portability and flexibility

Inactive Publication Date: 2012-07-11

HUAZHONG UNIV OF SCI & TECH

View PDF2 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The domestic research on light pen measurement technology has achieved certain results, such as the document "Acquisition of Feature Point Imaging Center in Probe Imaging Visual Coordinate Measurement System" published in 1998 on pages 14-20 of the fifth issue of the journal "Optical Precision Engineering" And in the document "Single Camera Measuring Probe Imaging Visual Coordinate Measurement System Modeling" published in "Journal of Instrumentation" No. 5, pp. 59-62 in 1999, a single camera measurement system is proposed, but there are limitations, such as accuracy Low, can only measure the distance, can not get the three-dimensional coordinates of the measured point; published in the journal "Optoelectronics Laser" No. 1 issue 85-88 in 2007 "Modeling of Optical Pen Type Single Camera 3D Coordinate Visual Measurement System" A hand-held visual measurement model with a single camera is proposed in the paper, and it is demonstrated that the single-camera light pen measurement system can measure three-dimensional coordinates in space, and a prototype is developed, but the model requires the hand-held light pen mark points to be strictly on a straight line, which increases the It is difficult to process, and it will inevitably bring some errors; in 2008, the document "Light Pen Type Three-Coordinate Measurement System Based on Binocular Stereo Vision" published on the 8th issue of the journal "China Mechanical Engineering" on pages 896-899 proposed A binocular stylus measurement model, but it still requires the marking points pasted on the stylus to be strictly on a straight line, and there are also disadvantages such as difficult processing and difficult to guarantee accuracy.

In addition, the light pen measurement technology can only measure one feature point data at a time, the measurement efficiency is low, and it is impossible to efficiently measure the three-dimensional data of the complex surface of the component surface

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example

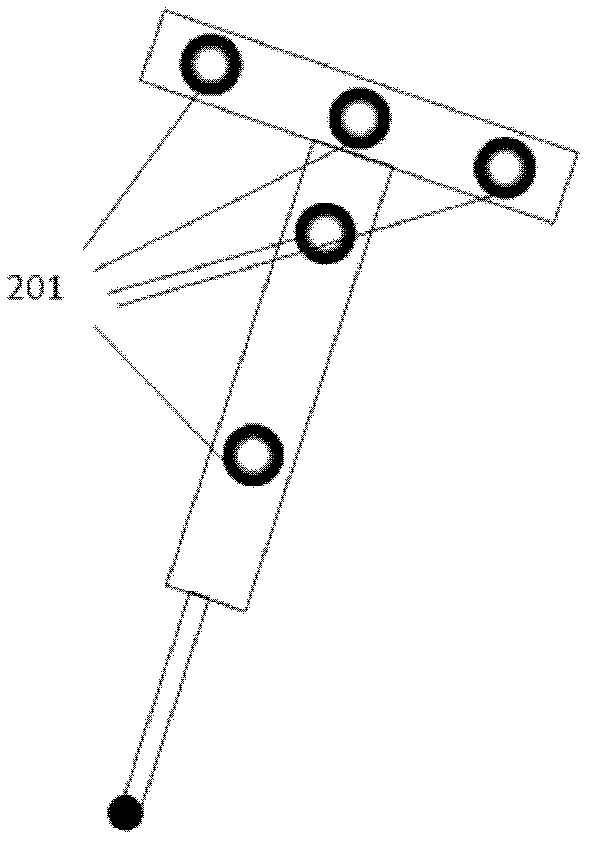

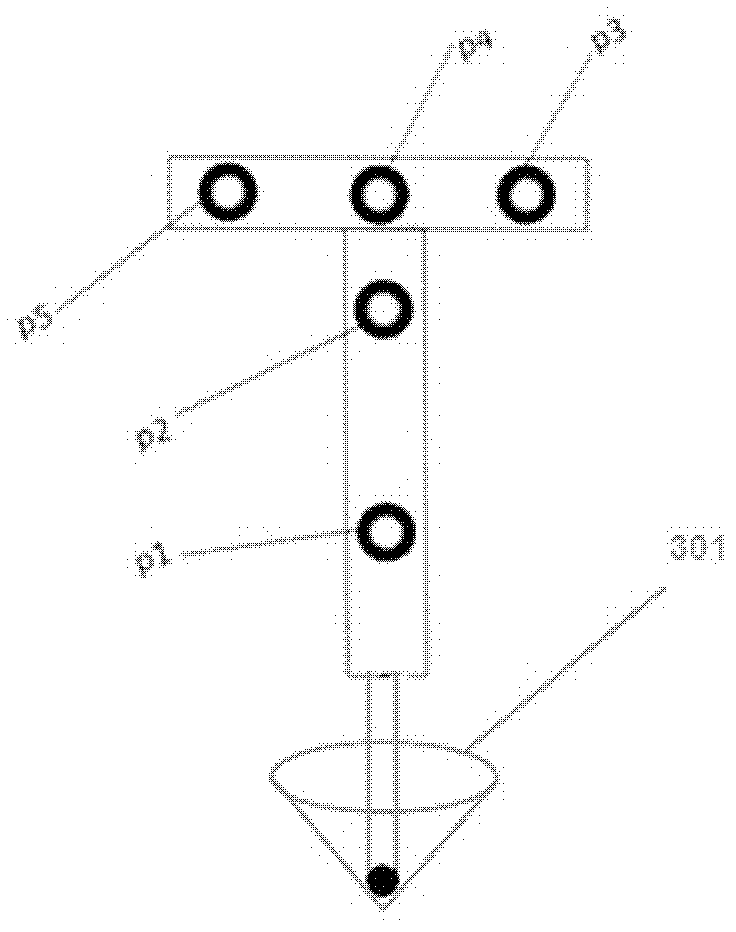

[0065] The digital projection device 101 adopts a projector, and the first and second digital cameras 102 and 103 all adopt black and white cameras, assuming λ 1 = 1 / 70, λ 2 = 1 / 64, λ 3 =1 / 59, the number of retroreflective mark points is 5.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

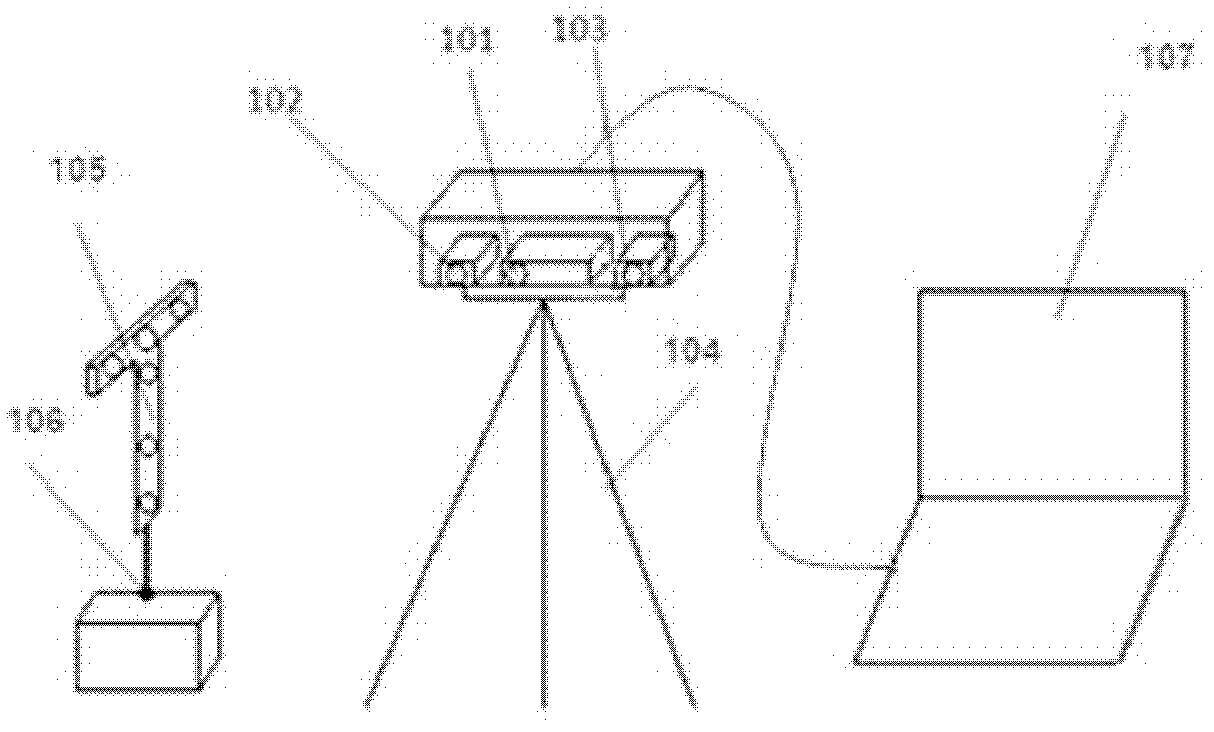

The invention belongs to the field of precise measurement and discloses a plane structured light and light pen-based precise three-dimensional measurement method for a complex part and a system for implementing the method. According to the method, the complex shape of the surface of the part is measured by a plane structured light three-dimensional measurement technology, the characteristic dimension such as an inner wall, a hole depth and the like of the part is measured by a light pen measurement technology, two digital cameras are shared by the technologies, and the three-dimensional data obtained by measuring can be automatically integrated to the same coordinate system, so a three-dimensional coordinate of an object point to be measured under a world coordinate system can be obtained. The system comprises a digital projection device, two digital cameras, a T-shaped rod, a measuring head and a computer. The advantages of high efficiency and accuracy and the like of the plane structured light three-dimensional measurement technology used for measuring the complex shape of the surface can be fully exerted, and the advantages of the light pen three-dimensional measurement technology used for measuring the characteristic dimension such as the inner wall, the hole depth and the like can be exerted. The special requirements of distribution of returned light reflection index points on the T-shaped rod are avoided, and the system has the advantages of high flexibility, convenience in carrying and the like.

Description

technical field [0001] The invention belongs to the field of precision measurement, and in particular relates to a method and system for precise three-dimensional measurement of complex parts based on surface structured light and a light pen. Technology to measure feature dimensions such as inner walls and deep holes of parts. Background technique [0002] The precise three-dimensional measurement of complex parts plays an important role in the fields of industrial design and quality inspection. At present, the commonly used measurement methods are generally divided into two types: contact type and non-contact type. The traditional contact three-coordinate measuring machine has high measurement accuracy, but it is expensive and has high requirements on the laboratory environment, so it cannot realize industrial on-site measurement. Non-contact measurement systems such as structured light can quickly obtain a large number of point clouds, but there is no way to obtain the th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01B11/25G01B11/00

Inventor 李中伟史玉升王从军雷玉珍钟凯

Owner HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com