Separation device for preparing free flow electrophoresis

A separation device and electrophoresis technology, applied in separation methods, dispersed particle separation, transportation and packaging, etc., can solve the problems of artificial shaking, defoaming and cooling, unevenness, etc., and achieve the effect of improving quality and uniform cooling area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

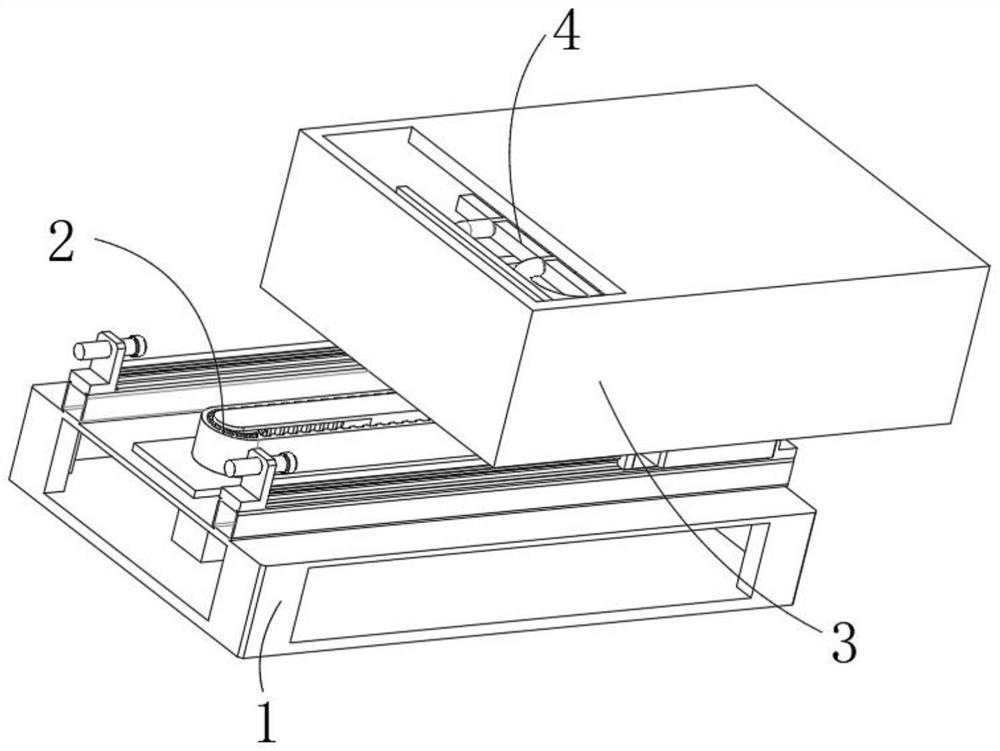

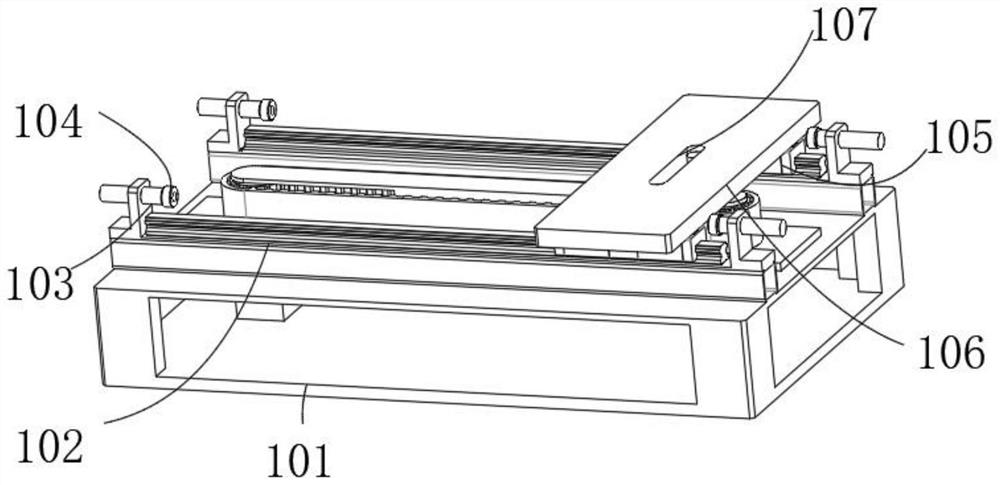

[0026] like Figure 1-5 As shown, the embodiment of the present invention provides a separation device for preparing free flow electrophoresis, including a main fixing mechanism 1, a uniform tiling mechanism 2, a separation mechanism 3 and a tiling cooling mechanism 4, and the top center of the main fixing mechanism 1 is fixedly connected There is a uniform tiling mechanism 2, a separation mechanism 3 is arranged on the top of the uniform tiling mechanism 2, and a tiling cooling mechanism 4 is fixedly connected inside the separation mechanism 3;

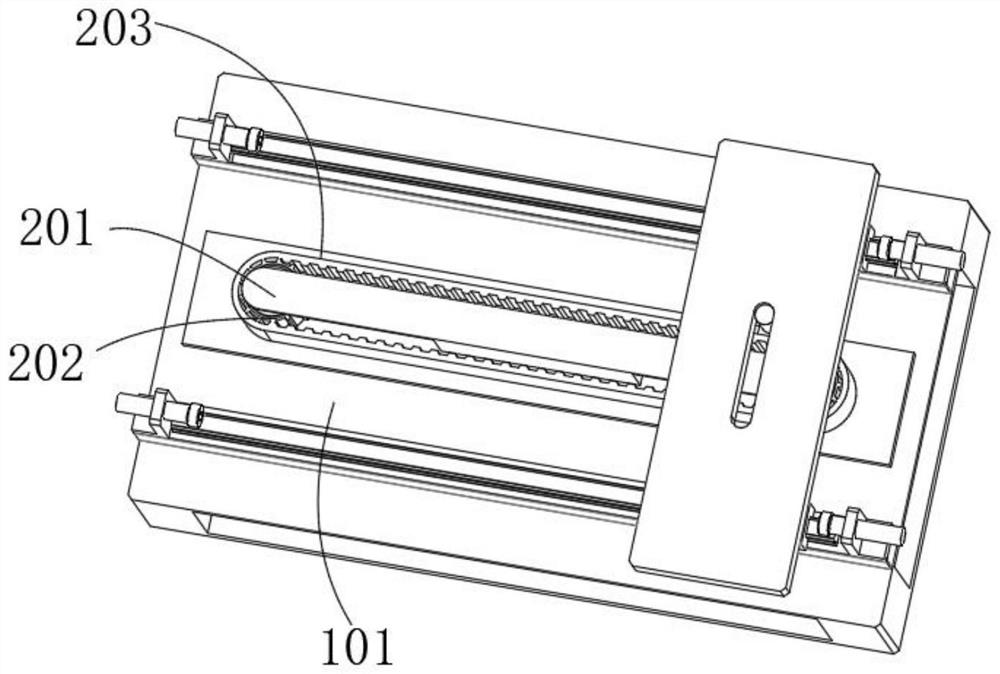

[0027] The uniform tiling mechanism 2 includes a fixed frame 201, an externally toothed pulley 202, an internal toothed belt 203, a linkage motor 204, a mosaic block 205 and a sliding column 206. The fixed frame 201 is fixedly connected to the top center of the base frame 101. The two sets of external toothed pulleys 202 are rotatably connected to each other, and the two sets of external toothed pulleys 202 are connected by an intern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com