Method for measuring and selecting gasket of taper bearing

A technology for tapered bearings and gaskets, which is applied in the field of tapered bearing gasket testing and selection methods and devices, and can solve problems such as reduction of the bearing capacity of the transmission system, reduced service life, and bearing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

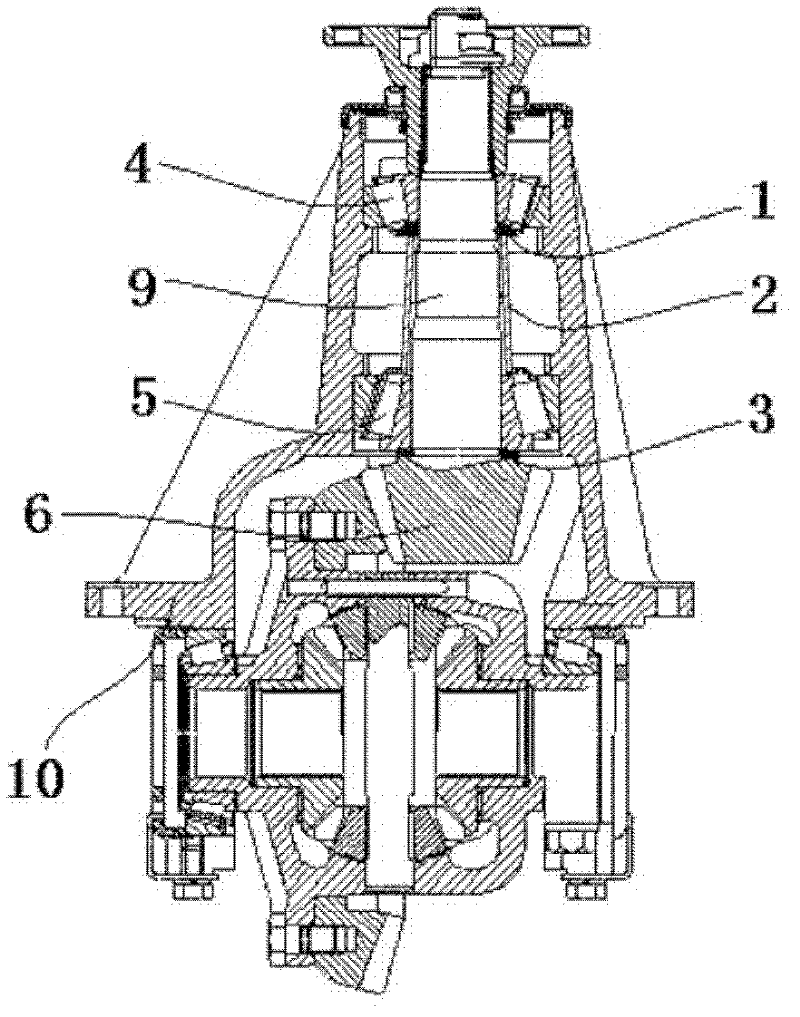

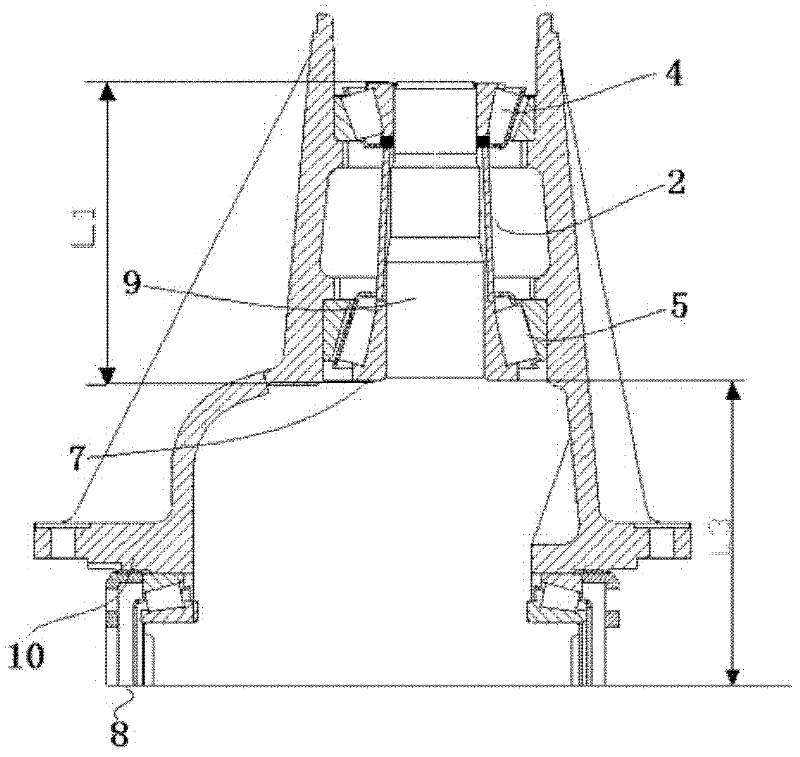

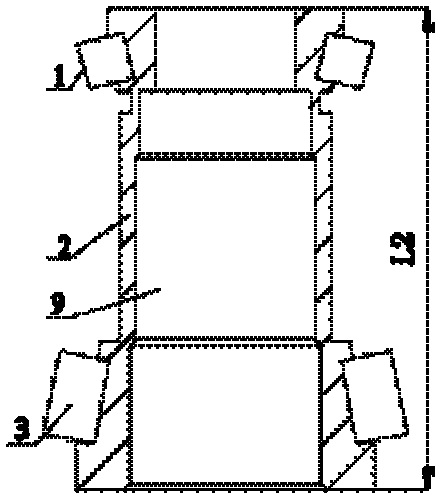

[0030] to combine Figures 1 to 3 As shown, it is a schematic diagram of the measured structure of the tapered bearing transmission system of the embodiment of the present invention; the method for measuring and selecting the tapered bearing gasket provided in this embodiment is a dynamic measurement, simulating the pressure and pressure of the tapered bearing transmission system in normal operation. Speed, measure the overall size under the actual working condition, and then compare it with the inner ring of the bearing inner ring of the upper cone bearing 4 and the lower cone bearing 5 and the size of the spacer 2 under the static state, and the difference is the thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com