Safety detection method and device of liquid

A safety detection and liquid technology, applied in the direction of material analysis using radiation, etc., can solve the problems of low detection accuracy, lack of products and technologies, and large detection error of effective atomic number, etc., to achieve the effect of improving detection accuracy and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Safety detection conditions: low-energy scanning tube voltage 80kV, tube current 0.7mA; high-energy scanning tube voltage 160kV, tube current 0.18mA. The projections of 400 angles are collected for one week of scanning, and the integration time of each angle projection is 5ms.

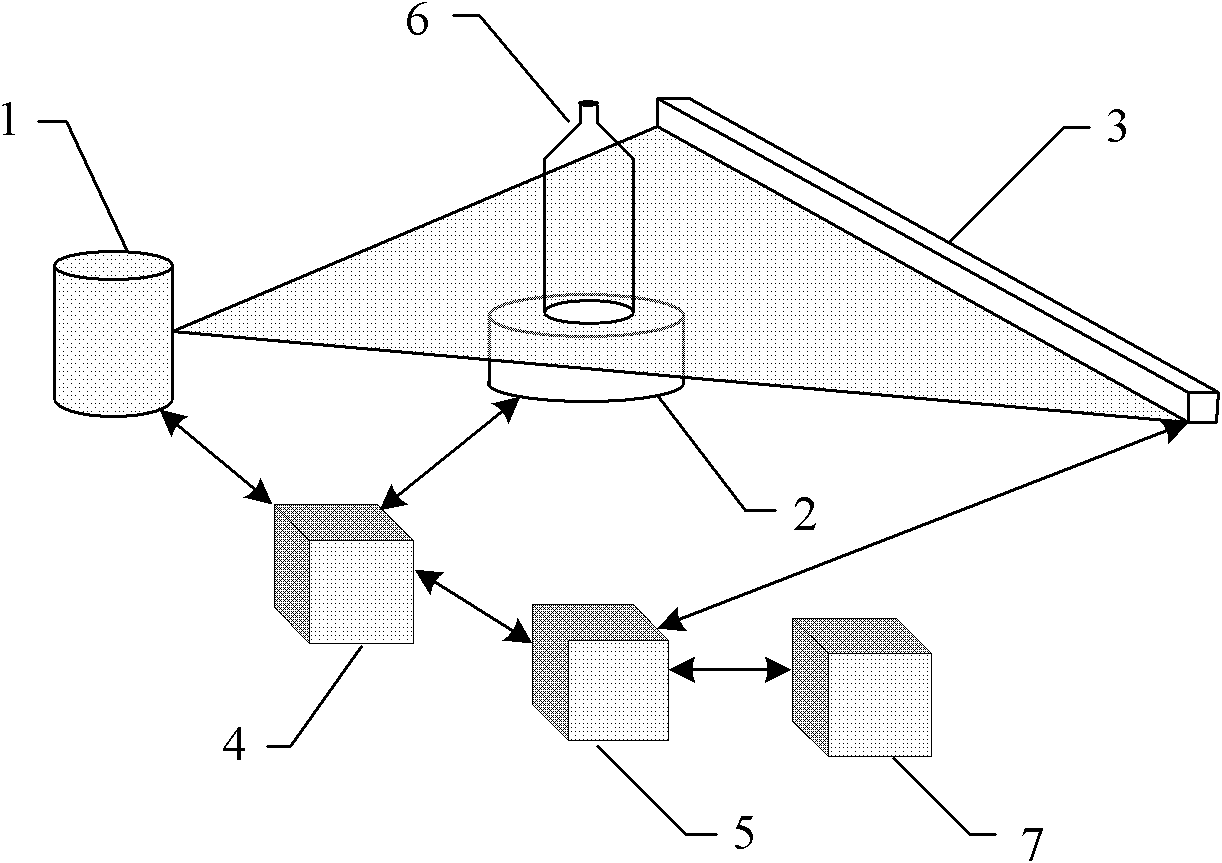

[0060] The schematic diagram of the safety detection device of the present invention can be found in figure 2 , the workflow is as follows:

[0061] 1) Use the barcode scanner 7 to scan the barcode on the packaging container of the detected liquid 6, and send the barcode information to the microprocessor 5 through the controller 4.

[0062] 2) Place the detected liquid 6 on the rotating platform 2 .

[0063] 3) The controller 4 is used to control the ray source 1 to turn on the ray, and at the same time control the rotation of the rotating platform 2 , and at the same time send a collection command to the microprocessor 5 .

[0064] 4) The microprocessor 5 controls the detector and collector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com