Capacitance humidity sensor with temperature drift compensation and making method thereof

A humidity sensor and temperature drift compensation technology, applied in the direction of material capacitance, etc., can solve the problems of complex circuits and large chip area, and achieve the effect of simple process, simple structure and overcoming temperature drift problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the content of the present invention more comprehensible, further description will be made below in conjunction with the accompanying drawings and specific embodiments.

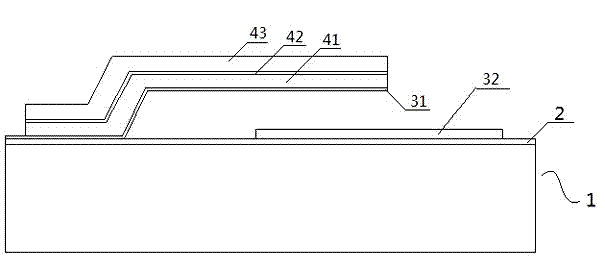

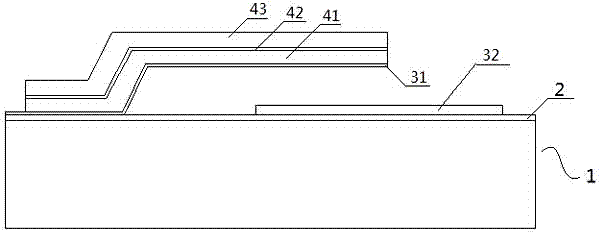

[0023] Such as figure 1 As shown, the capacitive humidity sensor with temperature drift compensation of the present invention includes a semiconductor substrate layer 1, an insulating layer 2, a humidity sensing cantilever and a sensing electrode; wherein:

[0024] The insulating layer 2 covers the upper surface of the semiconductor substrate layer 1;

[0025] One end of the humidity-sensing cantilever is fixed on the insulating layer 2, and the other end is located above the insulating layer 2 and suspended in the air; the humidity-sensing cantilever is composed of a first moisture-sensitive material layer 41, a moisture-proof layer 42 and a second moisture-sensing material layer stacked from bottom to top. Moisture-sensitive material layer 43 is formed, wherein the thickness of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com