Method for detecting high optical spectrum of composite insulator

A composite insulator and detection method technology, applied in the field of composite insulator detection, can solve the problems of single function, difficult to detect the deterioration of operating lines, and lack of mature methods, and achieve the effect of short time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples. Those skilled in the art can make various changes or modifications to the present invention, and these equivalent forms are also within the scope of the claims listed in this application.

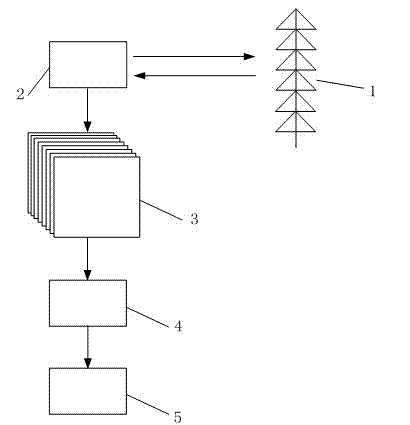

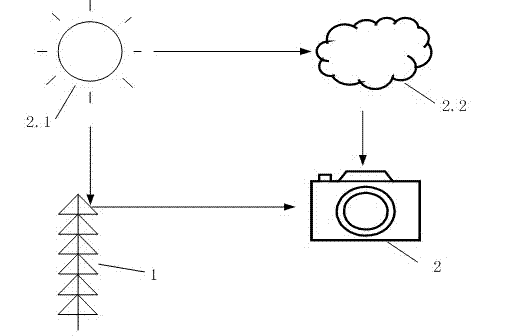

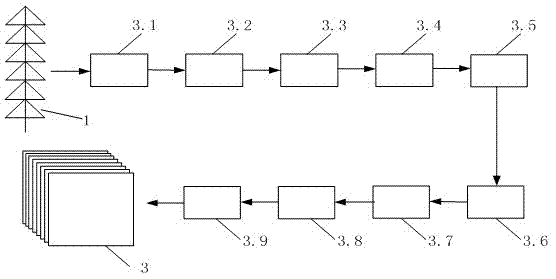

[0026] Notes in the drawings: 1-hyperspectral imager, 2-composite insulator, 3-hyperspectral image, 4-analysis platform, 5-judgment result output / display, 2.1-sunlight or other light sources, 2.2-atmosphere, 3.1-scanner, 3.2-objective lens, 3.3-slit, 3.4-collimator, 3.5-dispersive element, 3.6-lens, 3.7-detector, 3.8-processor, 3.9-output device, 4.1-hyperspectral image preview Processing, 4.2-identification of composite insulators, 4.3-quantitative analysis of aging degree of composite insulators, 4.4-judgment of hydrophobicity of composite insulators...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com