Optical fiber plug

An optical fiber plug and plug technology, which is applied in the field of optical communication, can solve the problems of difficult adaptation of the optical fiber plug, difficulty in assembly, influence of the strength of the optical fiber plug, etc., and achieve the effects of easy production and manufacturing, convenient connection and coordination, and convenient assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

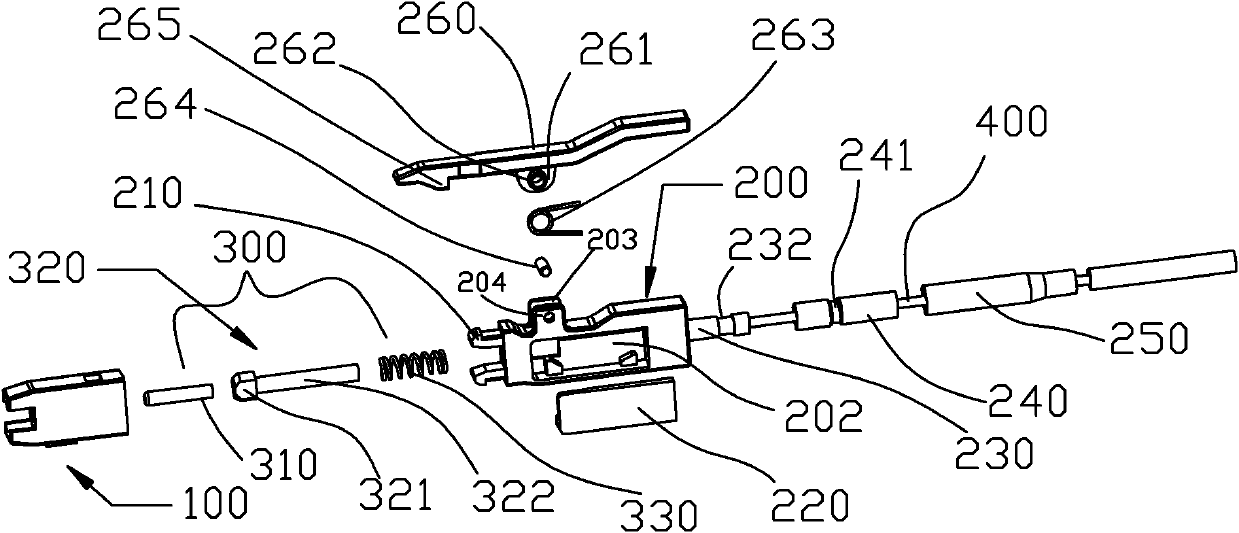

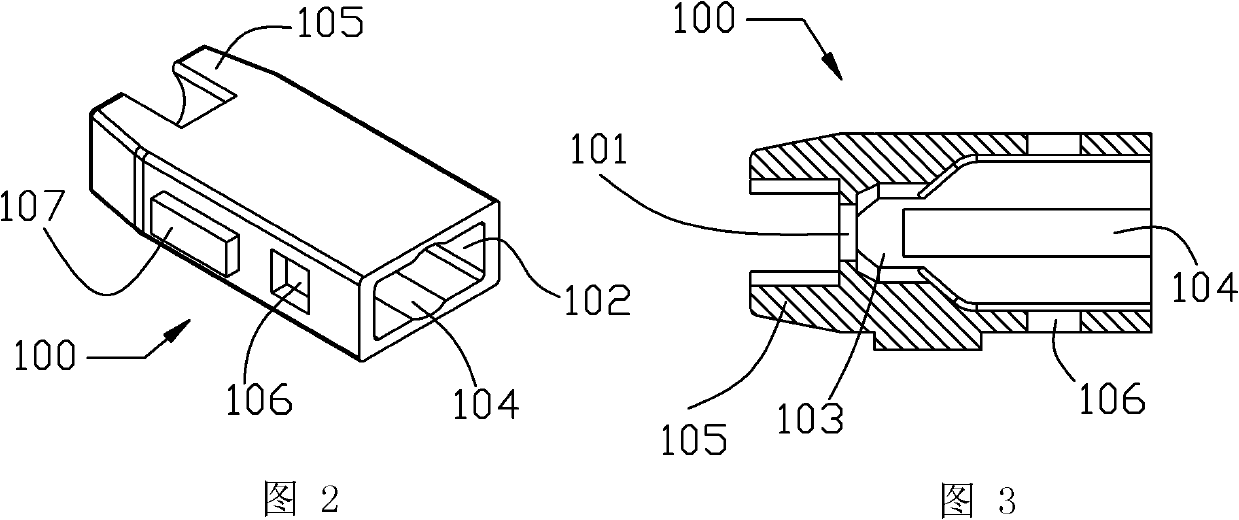

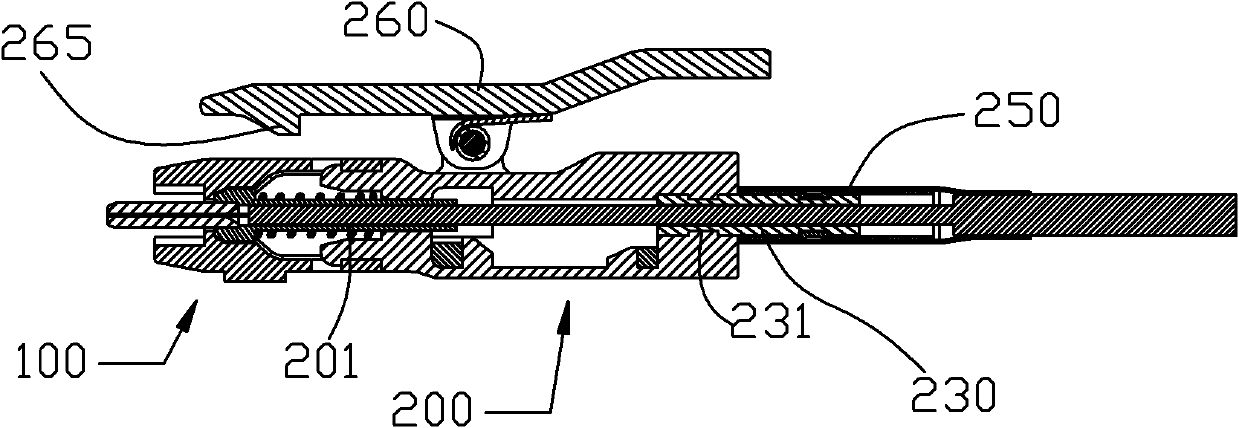

[0033] like Figure 1 to Figure 4 As shown, it is the first embodiment of the fiber optic plug of the present invention, the volume of this fiber optic plug is about 1 / 2 of the existing LC fiber optic plug, and the adapter of the same size can insert twice the number of fiber optic plugs of this embodiment , the connection density is doubled. The optical fiber plug includes a front housing 100 and a rear housing 200, and the front housing 100 and the rear housing 200 are fixedly connected.

[0034] The front end of the front housing 100 is provided with a first through hole 101, and the rear end of the front housing 100 is provided with an opening 102. The front housing 100 accommodates a ferrule assembly 300. The ferr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com