High-precision focusing device used for space optical remote sensing instrument

A space optical remote sensing, high-precision technology, applied in the field of space remote sensing, can solve the problems of difficult manufacturing, long-life lubrication of space cold welding, large influence on the machining accuracy of precision transmission parts, etc. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, a specific embodiment of the present invention is described in detail:

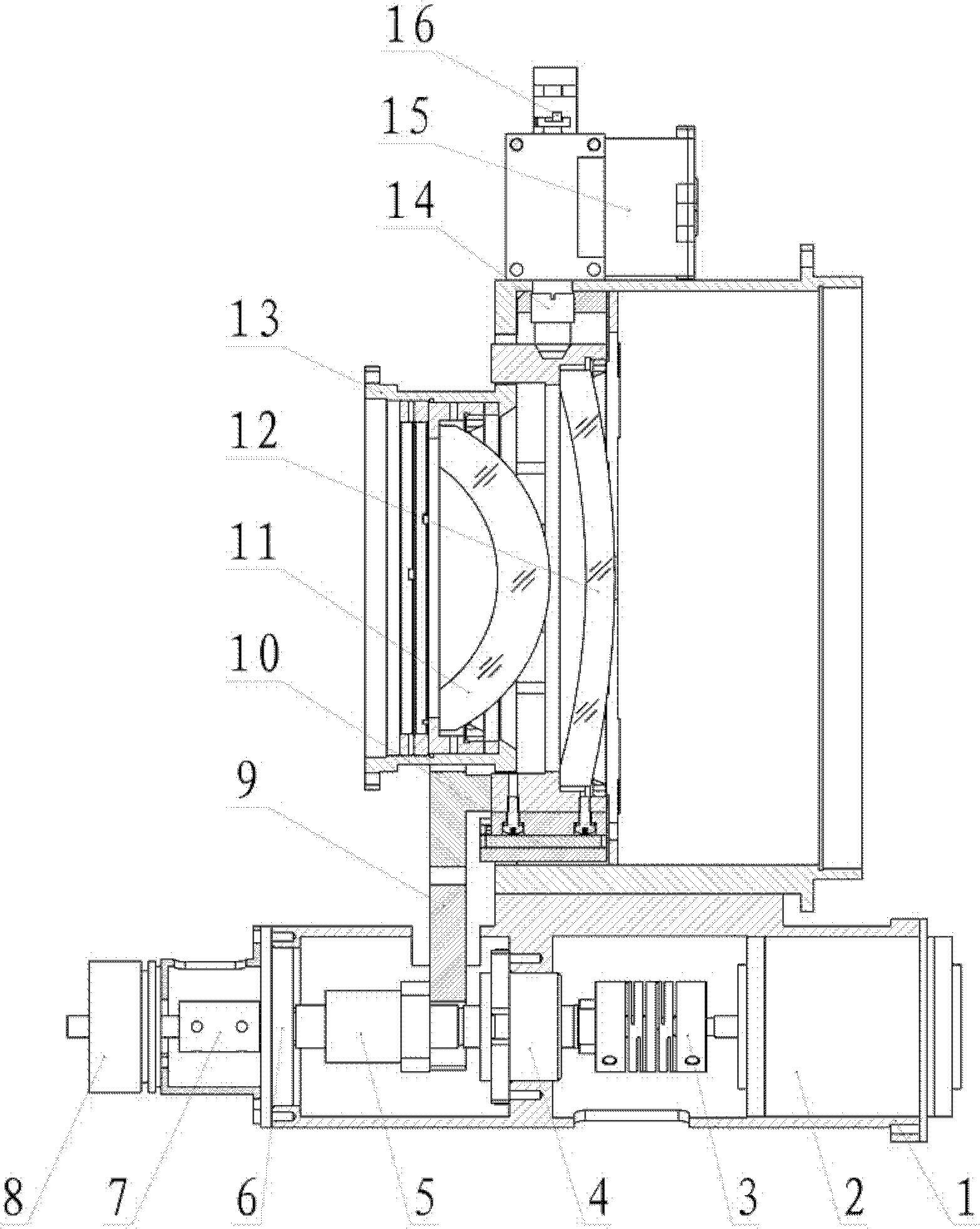

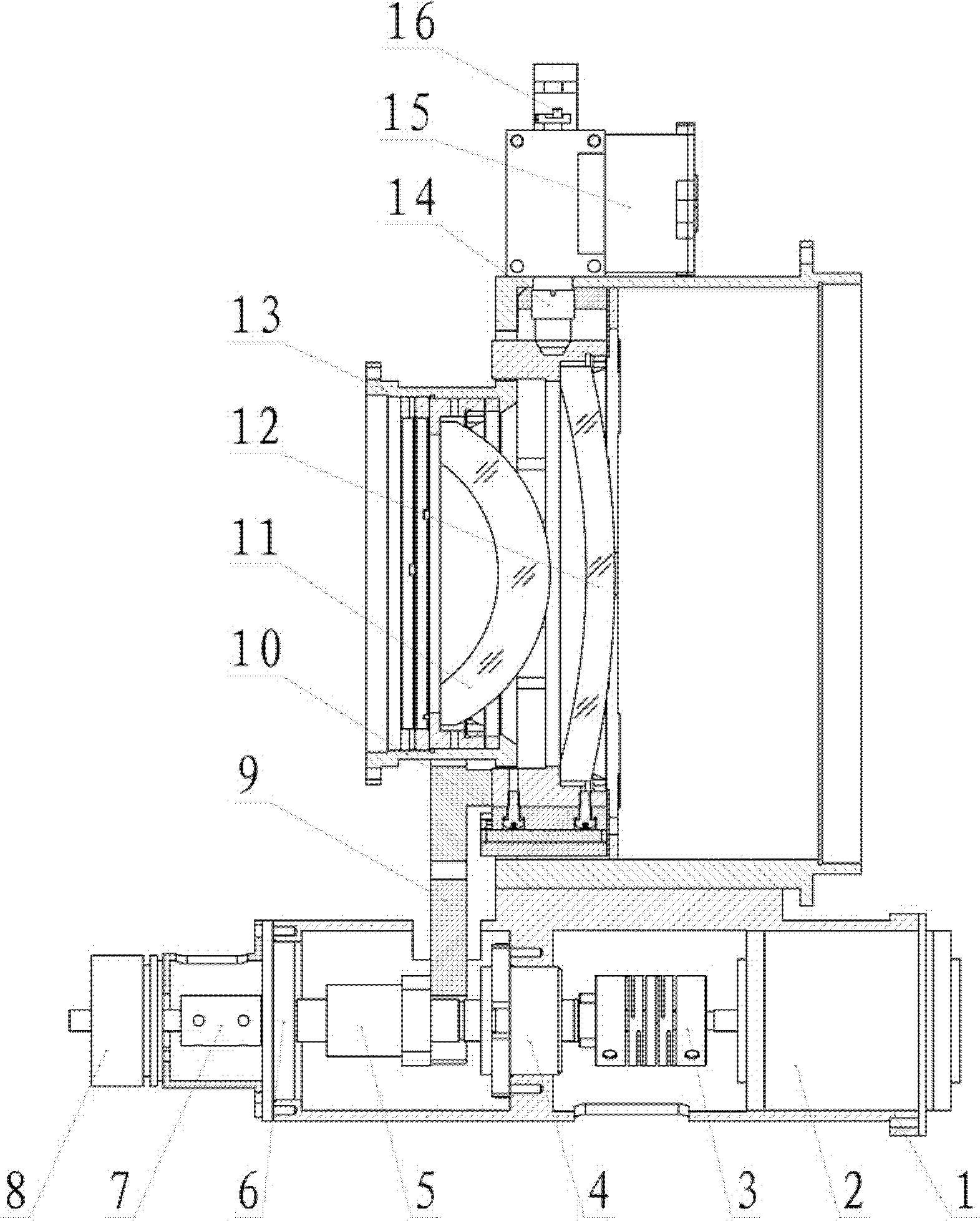

[0029] Such as figure 1 As shown, the focusing mechanism is installed in the focusing mechanism supporting tube 1 , and the fixed lens 11 and the focusing lens 12 are both installed in the lens supporting tube 13 . One end of the U-shaped focusing connecting frame 9 is installed on the nut seat of the precision ball screw 5, and the other end is fixed on the moving ring of the focusing lens. In order to facilitate the optical calibration of the entire optical system, it is necessary to ensure that the optical axis of the lens assembly is as consistent as possible with the mechanical axis of the lens support tube 13 . For this reason, in the design and processing process, ensure that the cylindricity of the two inner circles of the lens support tube 13, the focusing lens 12, and the fixed lens 11 are respectively less than 0.008mm, and the coaxiality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com