Liquid crystal display device and forming method thereof

A liquid crystal display device and liquid crystal layer technology, applied in the direction of instruments, optics, electrical components, etc., can solve the problems affecting the aperture ratio and transmittance of liquid crystal displays, hindering light from passing through liquid crystal display devices, etc., so as to improve the aperture ratio and facilitate Through, to achieve the effect of penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

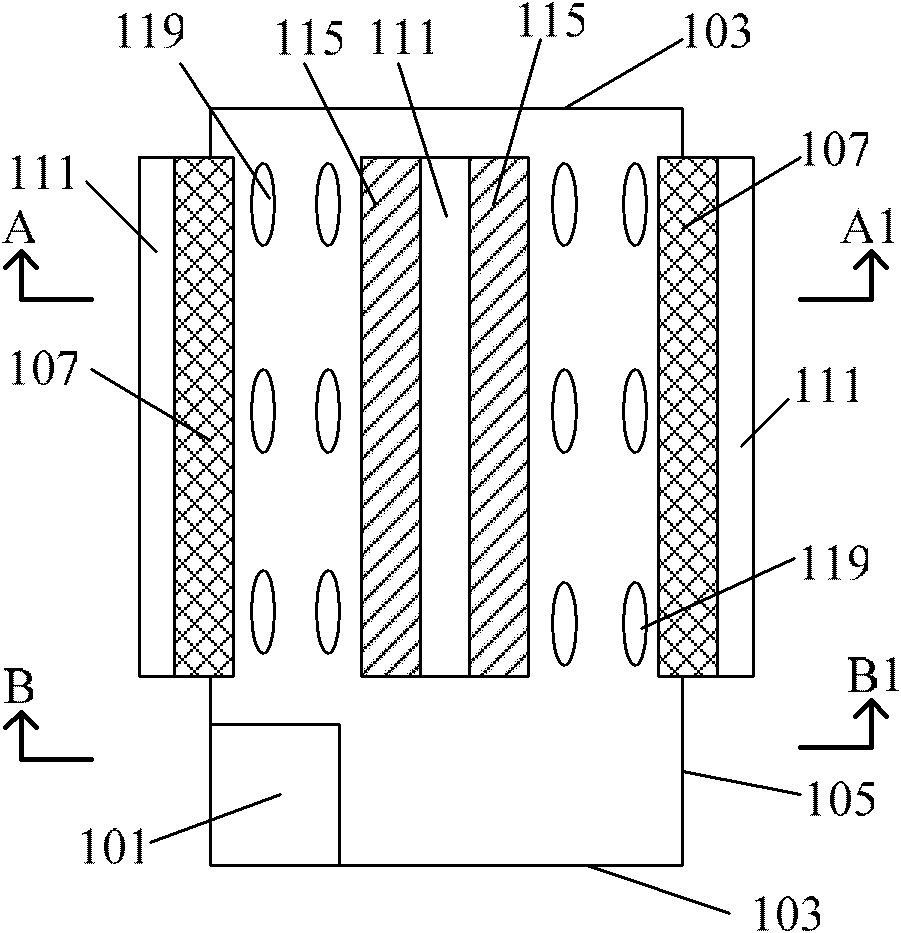

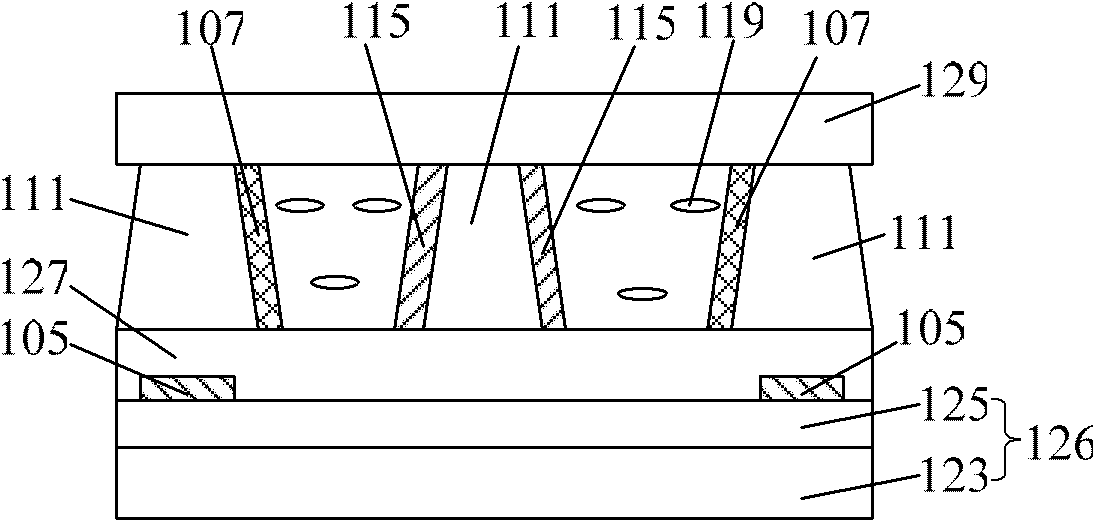

[0064] Please refer to image 3 and Figure 4 , image 3 It is a schematic structural diagram of a pixel unit of a liquid crystal display device according to the first embodiment of the present invention, Figure 4 yes image 3 A schematic cross-sectional structure diagram of the liquid crystal display device shown along line C-C1. The liquid crystal display device of the first embodiment of the present invention includes:

[0065] a first substrate 222;

[0066] a second substrate 223 opposite to the first substrate 222;

[0067] A plurality of spacers 211, 212 disposed between the first substrate 222 and the second substrate 223;

[0068] The liquid crystal layer 217 filled in the cavities formed by the plurality of spacers 211, 212, the first substrate 222 and the second substrate 223;

[0069] Each pixel unit in the liquid crystal display device according to the first embodiment of the present invention includes:

[0070] at least two spacers 211, 212;

[0071] Th...

no. 2 example

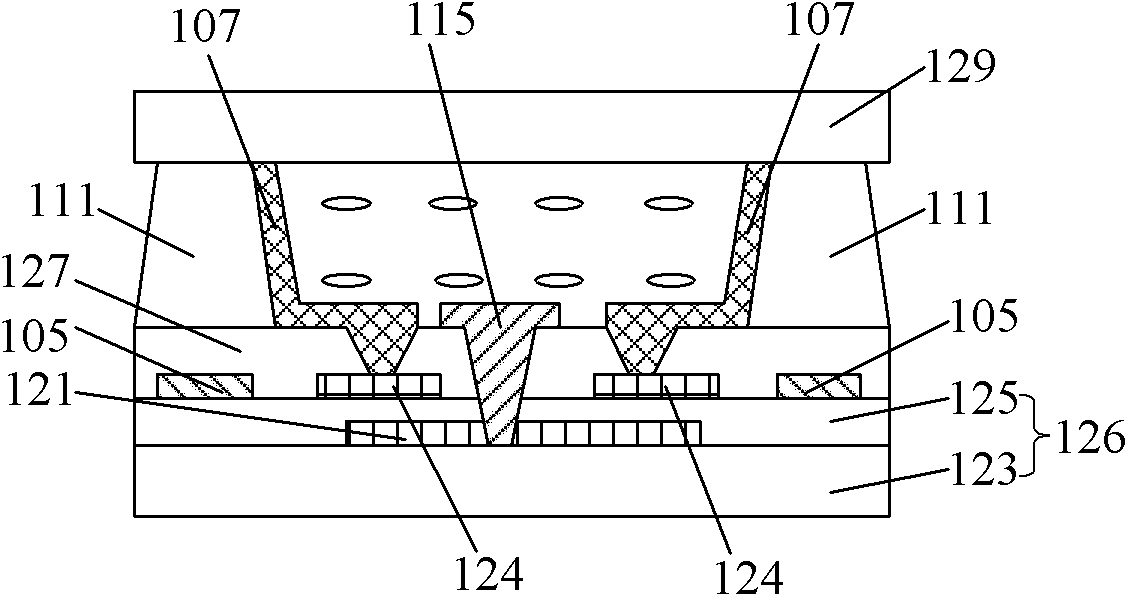

[0127] Please refer to Figure 6 and Figure 7 , Figure 6 is a schematic cross-sectional structure diagram of a liquid crystal display device according to the second embodiment of the present invention, Figure 7 yes Figure 6 A schematic cross-sectional structure diagram of the liquid crystal display device shown along line D-D1. The liquid crystal display device of the second embodiment of the present invention includes:

[0128] a first substrate 322;

[0129] a second substrate 323 disposed opposite to the first substrate 322;

[0130] A plurality of spacers 311, 312 disposed between the first substrate 322 and the second substrate 323;

[0131] a liquid crystal layer 317 filled in the cavities formed by the plurality of spacers 311, 312, the first substrate 322 and the second substrate 323;

[0132] Each pixel unit in the liquid crystal display device of the present invention comprises:

[0133] at least two spacers 311, 312;

[0134] The first substrate 322 or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com