Method for testing diaphragm of illumining system of photoetching equipment

An illumination system and test light technology, which are applied in microlithography exposure equipment, photometric exposure devices using electrical radiation detectors, and photolithographic process exposure devices, etc., can solve problems such as inability to determine illumination pupil photodetectors, inaccuracy, etc. , to achieve the effect of improving the test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

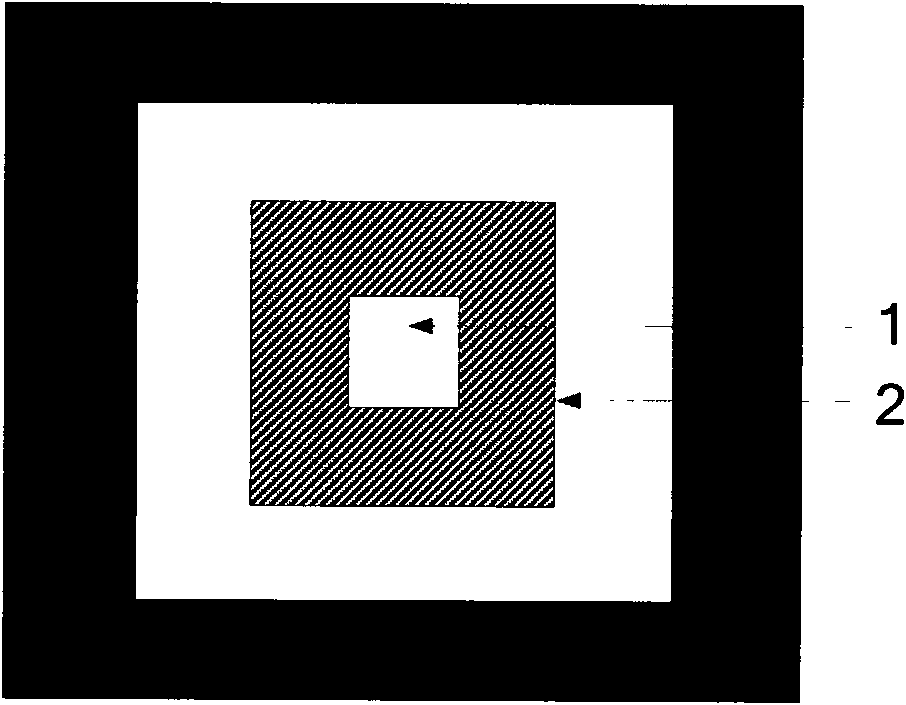

[0031] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] The object of the present invention is to provide a method for testing the pupil of an illumination system applied in lithography equipment, which is referred to as a pupil testing method for convenience of description below. The pupil testing method can accurately and completely measure the light intensity sampling data and the pupil position distribution in the pupil plane in the illumination system.

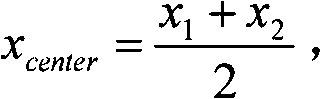

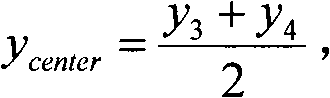

[0033] The present invention utilizes a special pupil test mask that can function as a diaphragm, and at least one aperture that can be used for position calibration and pupil test in the field of view is arranged on the mask, and the small aperture is calibrated by the boundary scan method. The center position of the aperture, and then perform an accurate pupil distribution test at this calibrated position. The specific implementation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com