Method for manufacturing encapsulation structure for light-emitting diode

A technology of light-emitting diodes and packaging structures, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., and can solve the problems affecting the uniformity of light output or color rendering of the packaging structure of light-emitting diodes, excessive deviation of the outside of the reflective cup or dispensing position, overflow of glue or packaging In order to improve the uniformity of light output and color rendering, prevent the formation of unevenness, and achieve the effect of precise movement and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

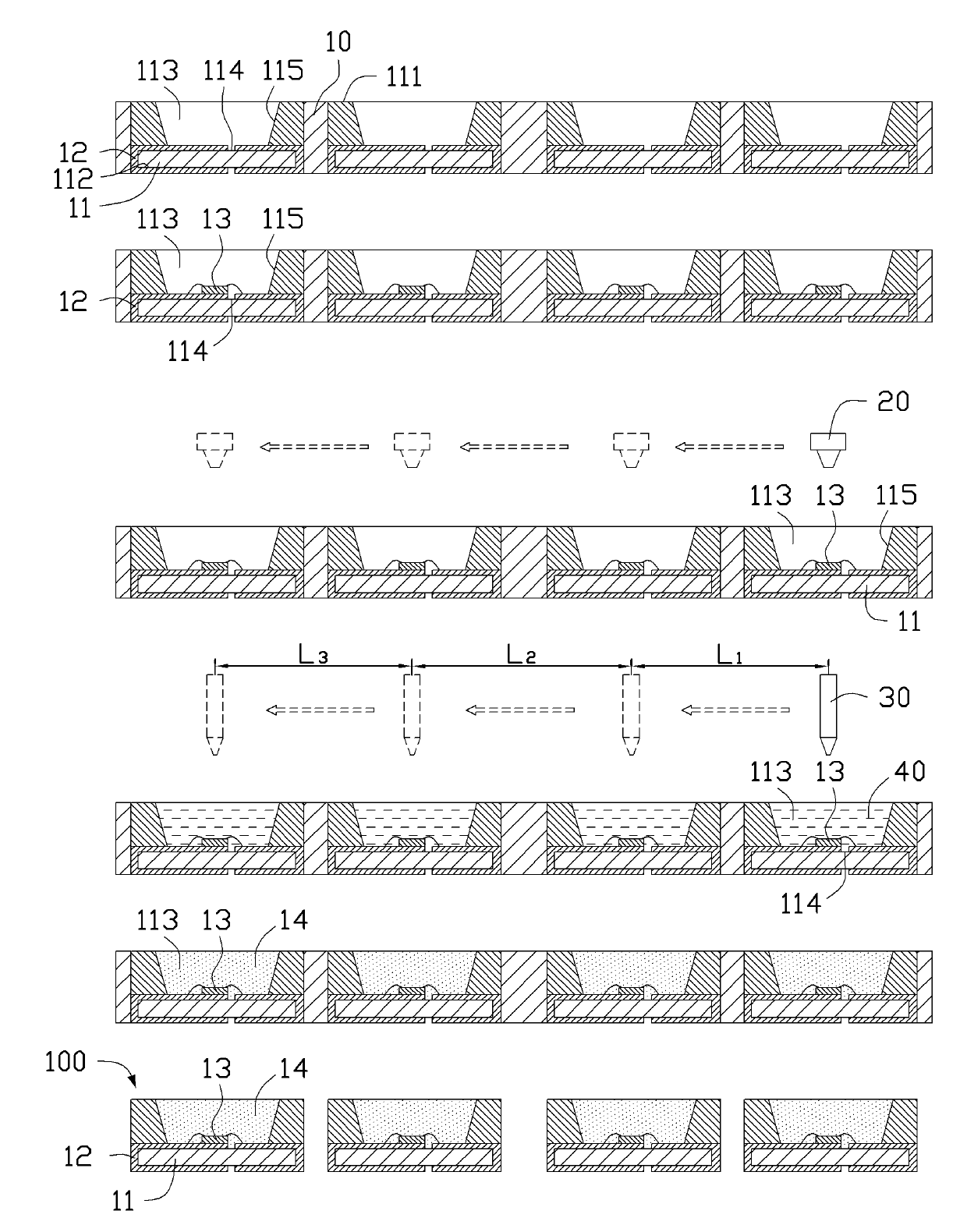

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings.

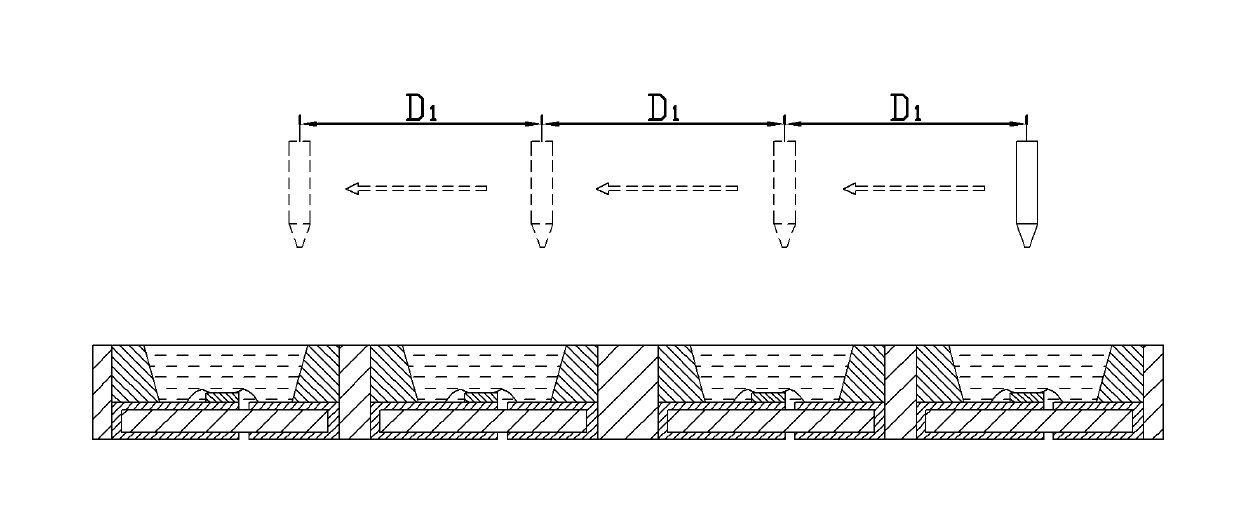

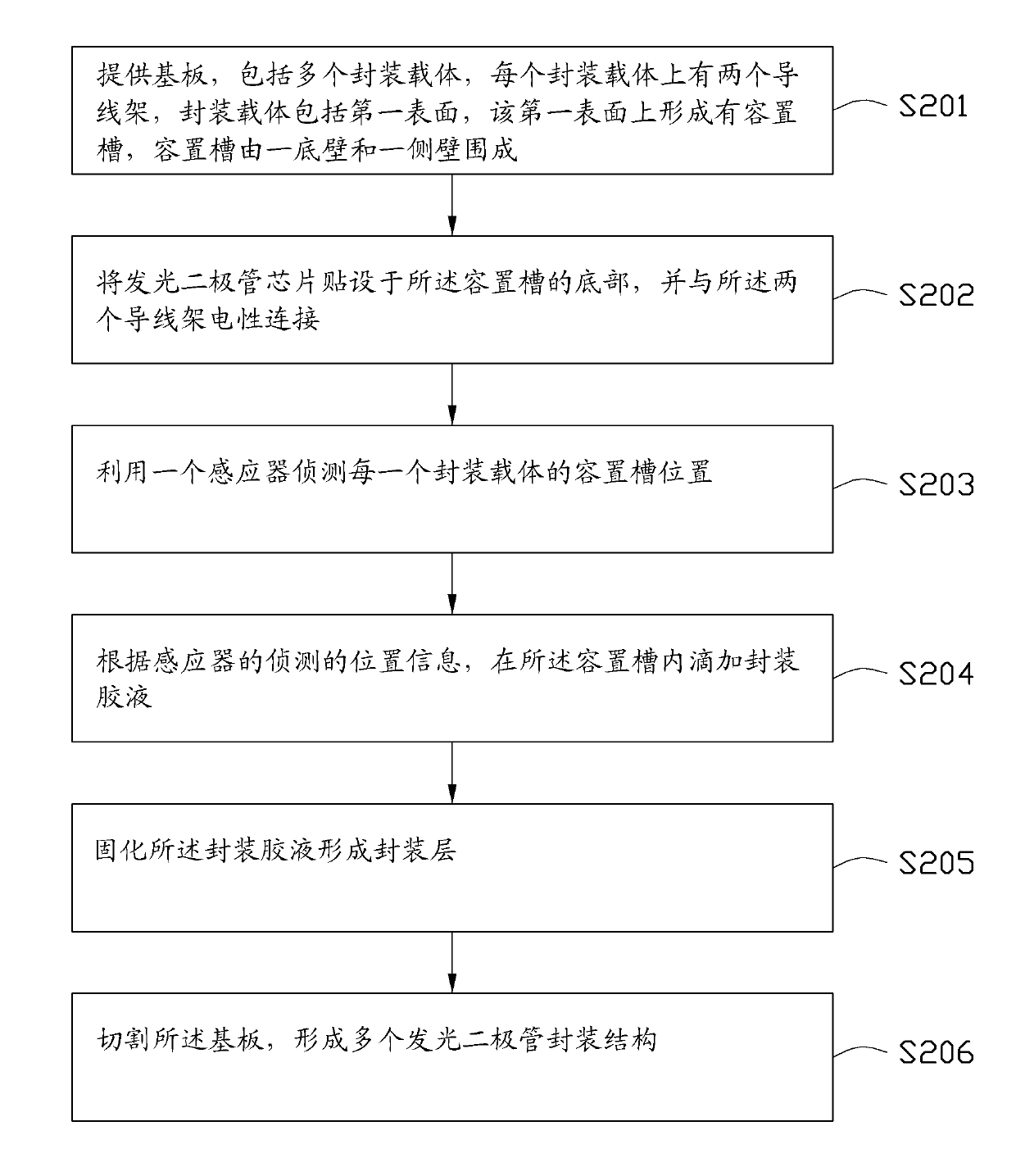

[0032] see figure 2 and image 3 A method for manufacturing a light emitting diode packaging structure provided in an embodiment of the present invention includes the following steps.

[0033] Step S201 : providing a substrate 10 . The substrate 10 includes a plurality of package carriers 11 , and each package carrier 11 has two lead frames 12 on it. The package carrier 11 includes a first surface 111 and a second surface 112 opposite to each other. An accommodating groove 113 is formed on the first surface 111 . The accommodating groove 113 is surrounded by a bottom wall 114 and a side wall 115 . The bottom wall 114 and the side wall 115 can be integrally formed or fixed by glue or the like. In this embodiment, the bottom wall 114 and the side wall 115 are integrally formed. The package carrier 11 can be made of high thermal conductivity and electrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com