Annular backward pumping structure of high-power all-fiber laser

A technology of reverse pumping and lasers, applied to the structure/shape of optical resonators, the structure/shape of active media, lasers, etc., can solve problems such as increased energy consumption, increased coil space, nonlinear effects, etc., to achieve The effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

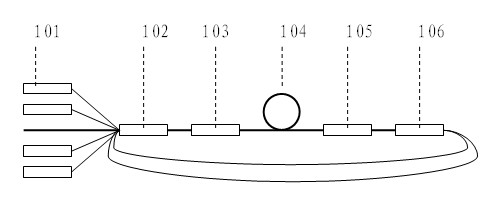

[0013] see first figure 1 , figure 1 It is a block diagram of the annular reverse pumping structure of the high-power all-fiber laser of the present invention. As can be seen from the figure, the annular reverse pumping structure of the high-power all-fiber laser of the present invention comprises a semiconductor laser pumping source 101 with a fiber pigtail, a beam combiner 102, a low-inverse fiber Bragg grating 103, and a gain fiber 104. , a high inverse Bragg grating 105 and a beam splitter 106, the beam combiner 102 is a (n+1)x1 beam combiner, including n pump light input fibers and 1 central main fiber, the split The beam splitter is a 1-m-way beam splitter, and the tail fibers of the n-m semiconductor lasers as the pumping source 101 are connected to the n-m input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com