Assembling technology for far-infrared electric-heating air-conditioning heating module

An assembly process and far-infrared technology, used in electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of limited heat absorption, large energy consumption, poor heating effect, etc., to reduce production costs, simplify manual operations, Good production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0097] see Figure 1~35 , the present invention relates to an assembly process of a far-infrared electric heating air-conditioning heating module, the steps of the process are:

[0098] Step 1, substrate cutting;

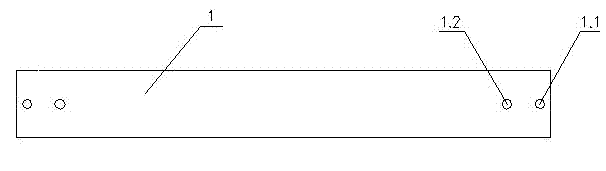

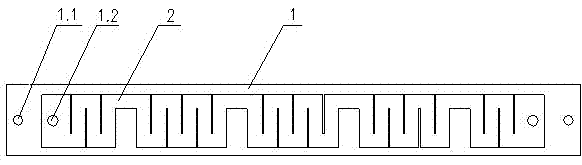

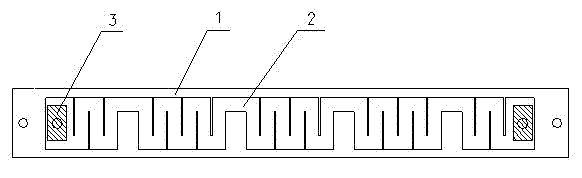

[0099] The glass fiber board is cut to form the substrate 1. The substrate 1 is a rectangular structure. It can also be made into different shapes according to the actual situation during actual manufacturing, and the two ends of the substrate 1 are processed to form positioning holes 1.1 and 1.1 respectively. The conductive hole 1.2, and the positioning hole 1.1 is located outside the conductive hole 1.2 (such as figure 1 shown); the whole process uses a cutting die to cut and shape at one time, see Figure 23~25 , the cutting mold includes a cutting mold lower mold 11 and a cutting mold upper mold 12, the cutting mold lower mold 11 includes a cutting mold lower mold bottom plate 11.1, and the cutting mold lower mold bottom plate 11.1 is installed There are guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com