Method for turning eccentric shaft

A technology of eccentric shaft and car eccentric, which is applied in the processing field of eccentric shaft and can solve problems such as inappropriate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

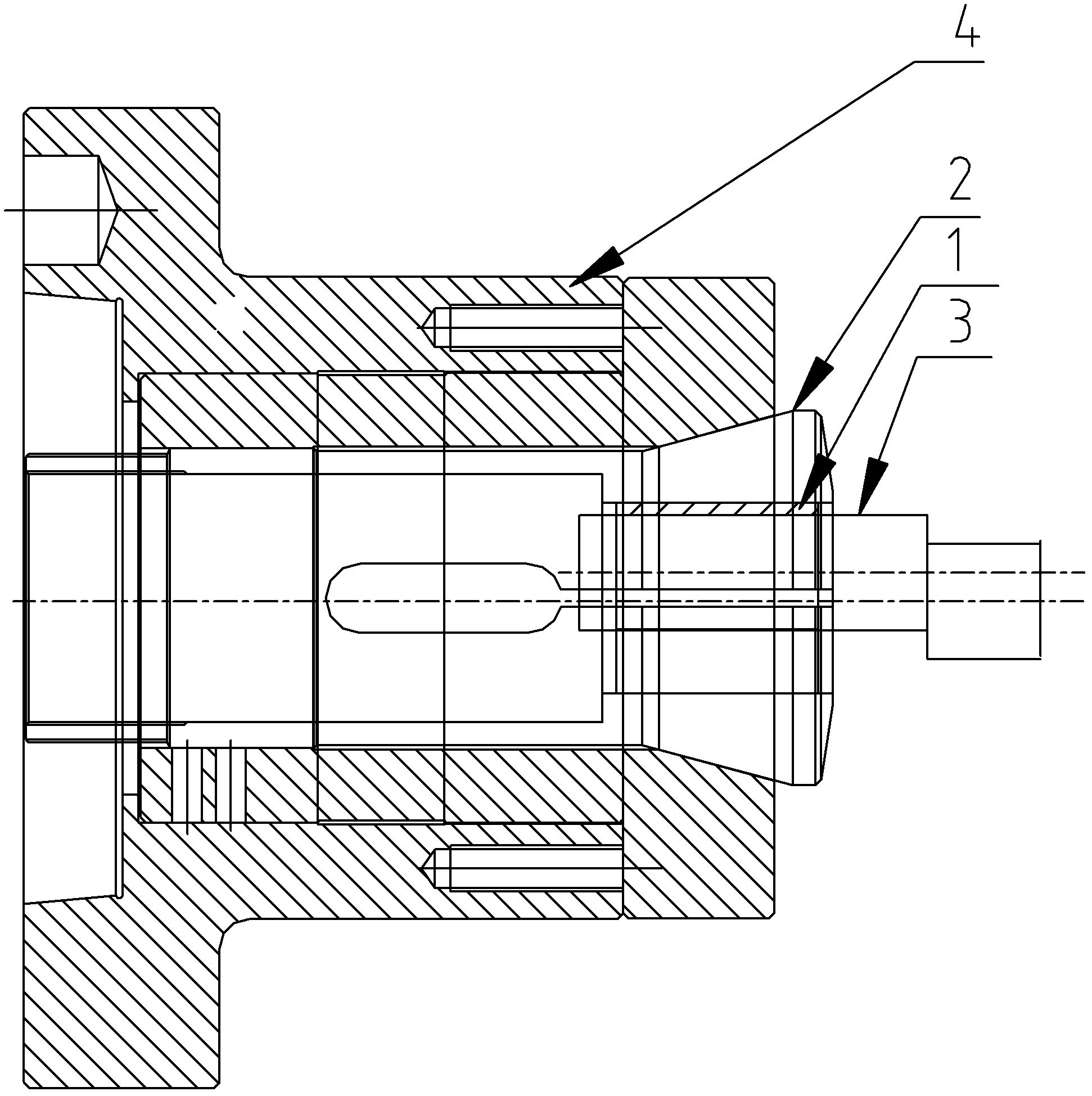

[0018] combine Figure 1 to Figure 6 , a method for turning an eccentric shaft, comprising the steps of:

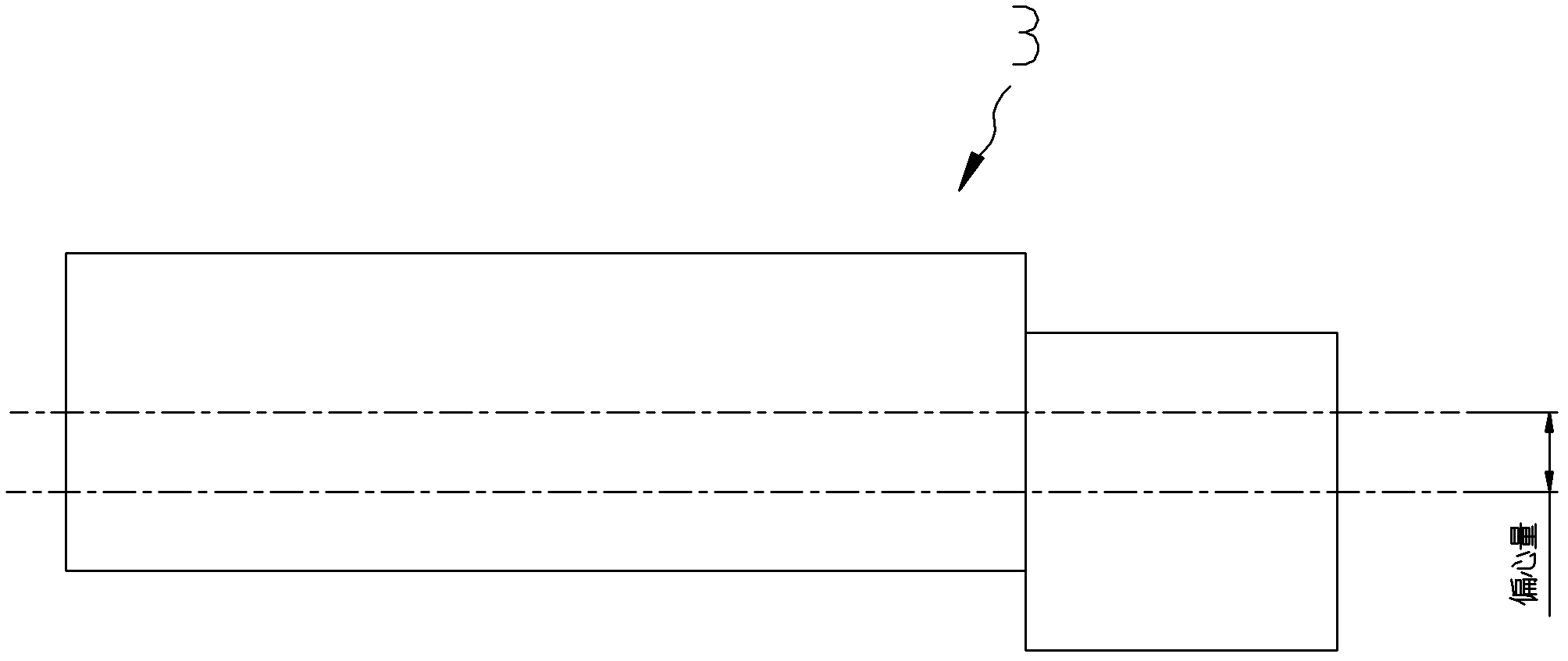

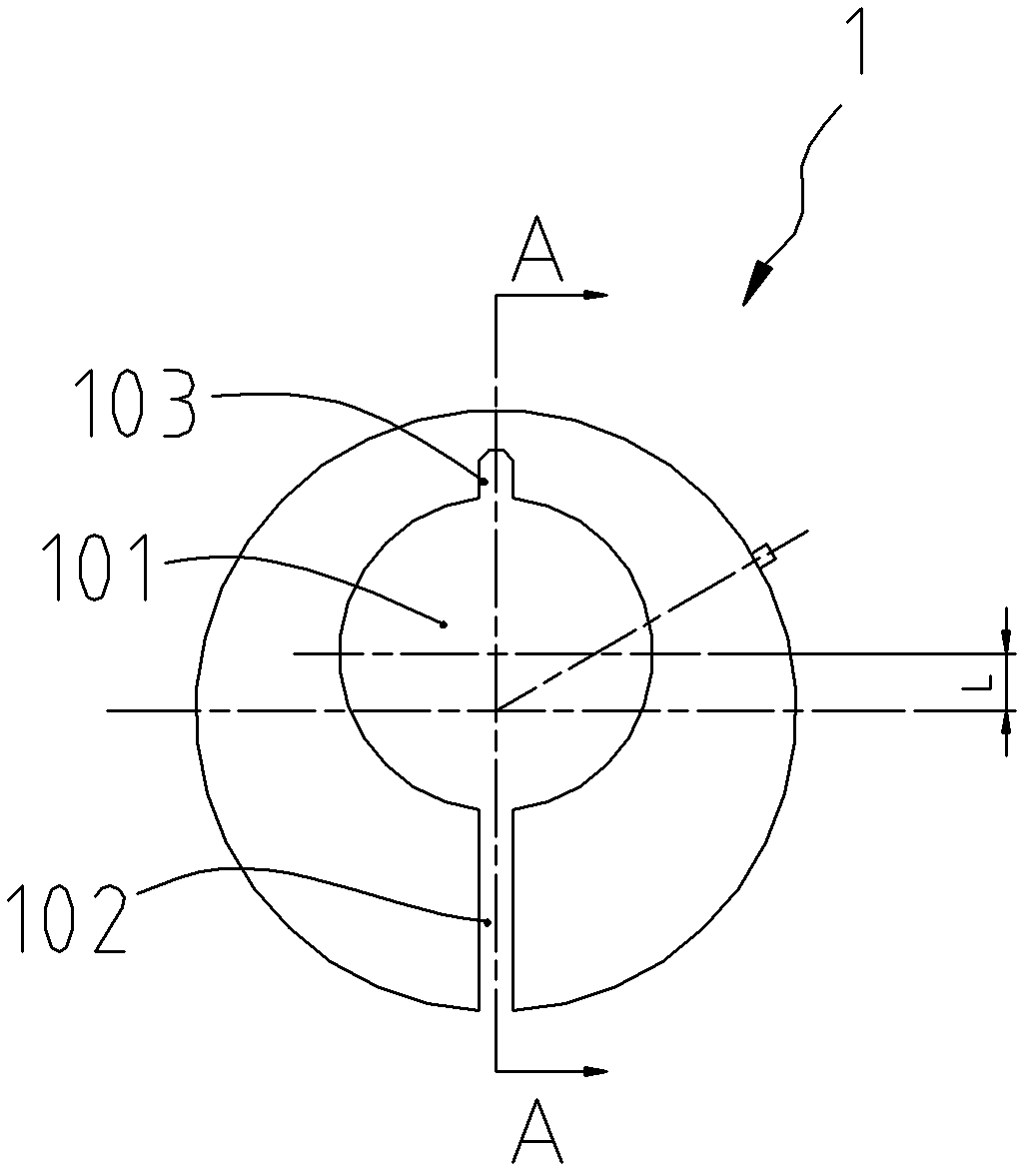

[0019] Provide processing machine tools, several optional eccentric collets 1, elastic collets 2 and eccentric shaft workpieces 3. Only one eccentric collet 1 is shown in the figure. The above-mentioned eccentric collet 1 is provided with an eccentric shaft hole 101 capable of satisfying a set eccentricity, and L in the figure is the set eccentricity. Preferably, from the perspective of the cross-sectional structure of the eccentric collet, the cylinder wall gradually thickens from top to bottom, and a lower opening 102 parallel to the axis (axis line) of the eccentric collet is provided on the bottom cylinder wall; The wall is provided with an inner notch 103 recessed from the side of the eccentric shaft hole to the cylinder wall for a section. The inner notch is also parallel to the axis of the eccentric collet, and the position of the inner notch is directly opposite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com