Method for mounting internal assemblies of large container

A technology for installation of large containers and components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

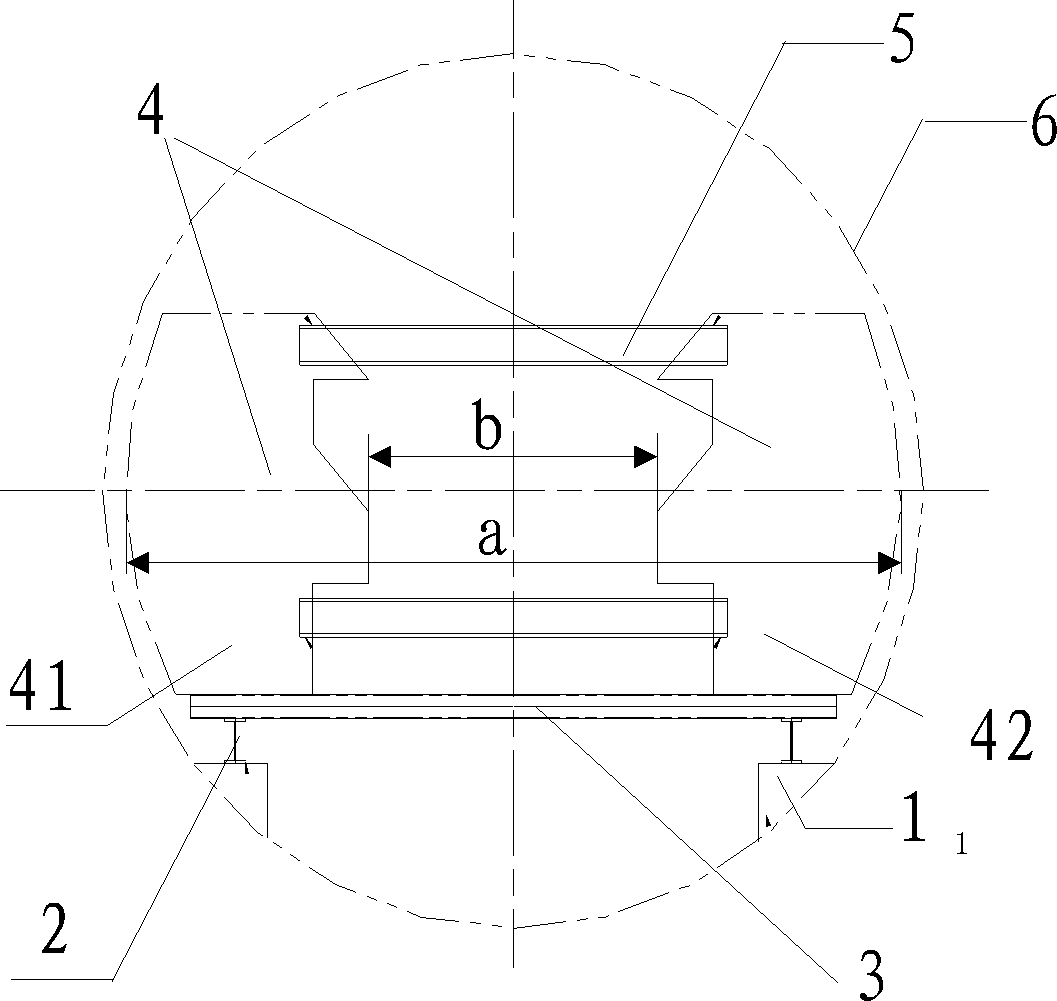

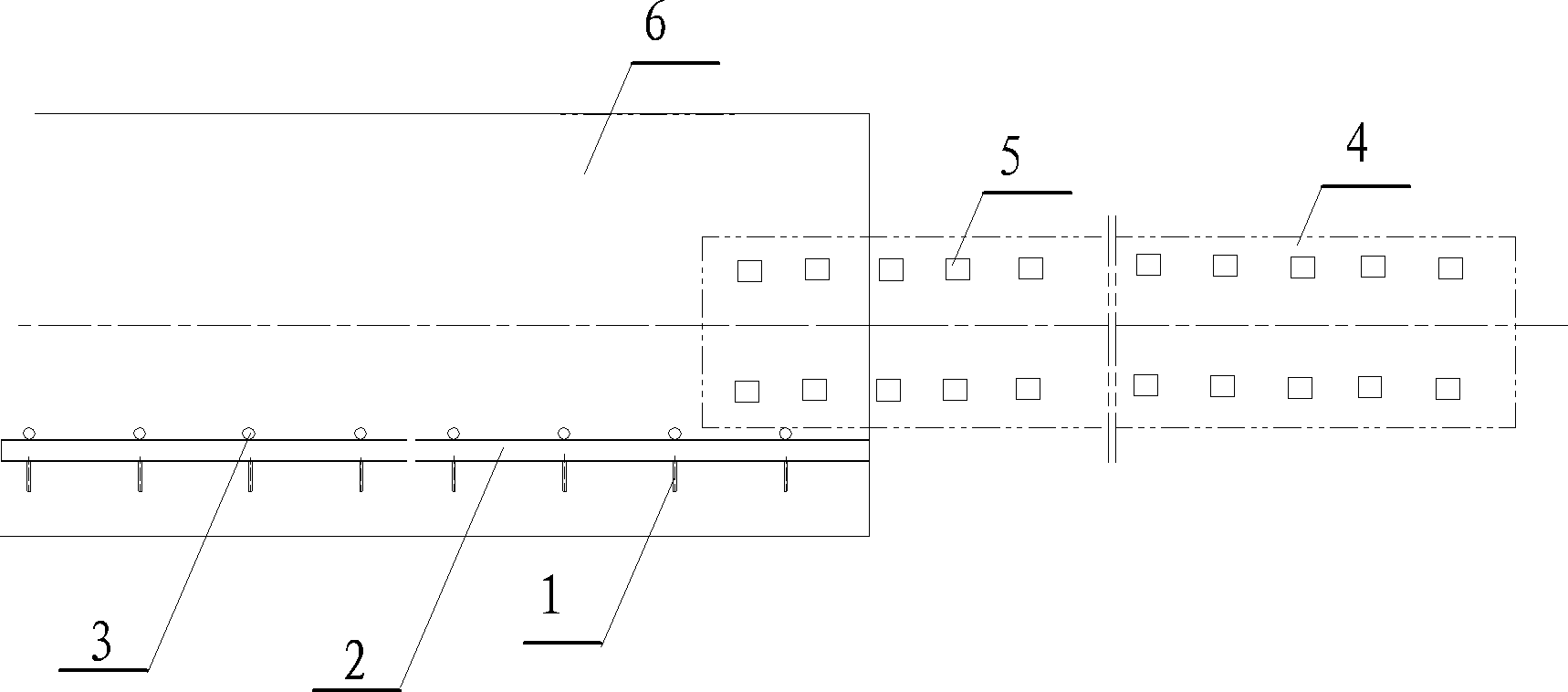

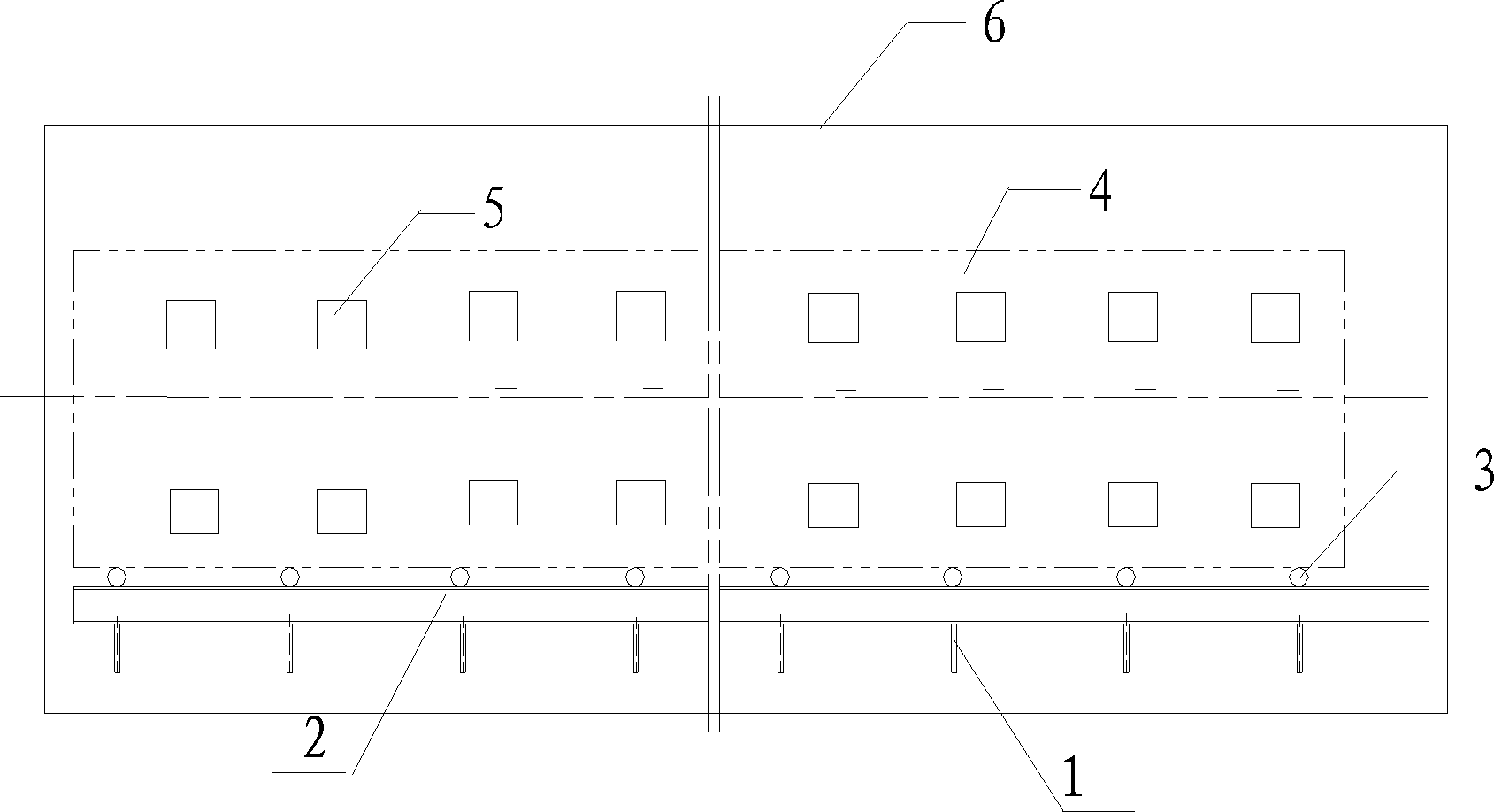

[0024] see Figure 1 to Figure 4 , in order to better understand the technical solution of the present invention, the following will be described in detail through specific embodiments and in conjunction with the accompanying drawings:

[0025] When using a method for installing internal components of a large container according to the present invention, one axial end of the large container 6 is opened to form an opening of the large container. figure 2 , the opening of the large container is located on the right side of the large container in the axial direction.

[0026] A method for installing internal components of a large container according to the present invention includes the following steps: a step of setting a mounting bracket, an installation step of assembling an internal integral component, a step of installing an internal integral component, a radial positioning step of an internal integral component, and a removal step.

[0027] see figure 1 and figure 2 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com