Intelligent shock-absorbing standard worktable for machine tool

A workbench and workbench base technology, which can be used in manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve problems such as non-adaptive ability, improve cutting speed and surface roughness accuracy, and widen sources of raw materials. , strengthen the effect of relative rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

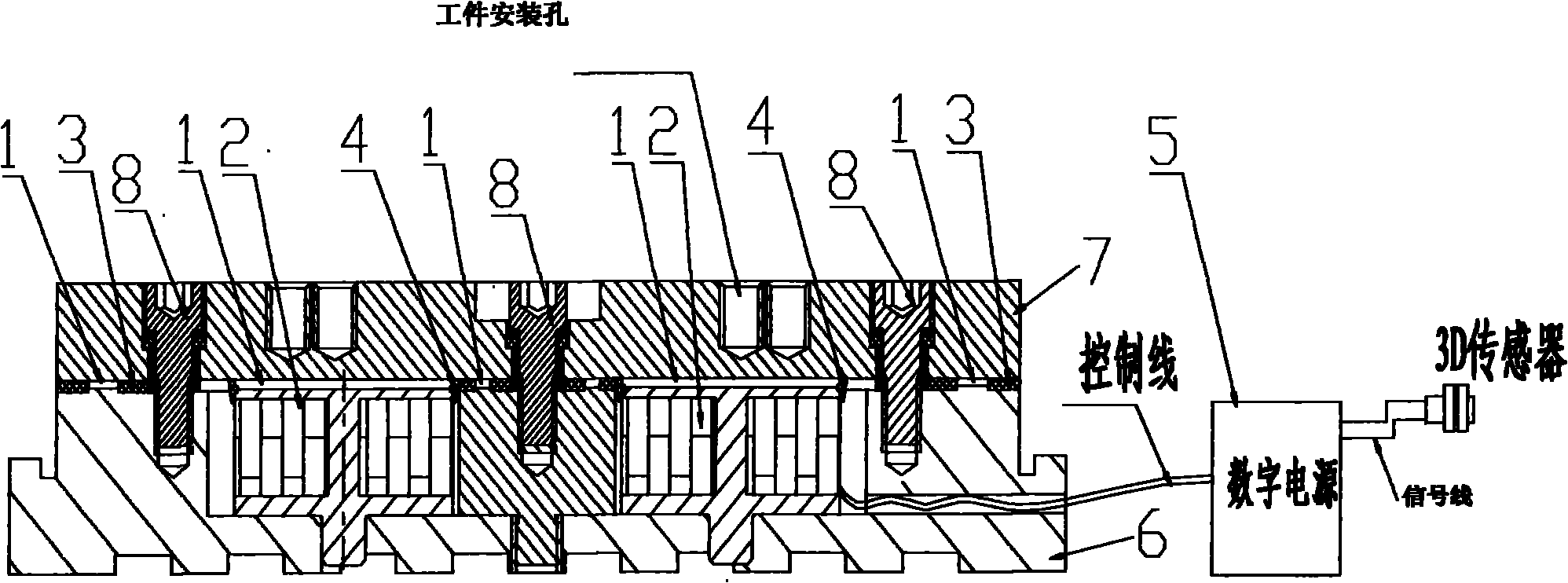

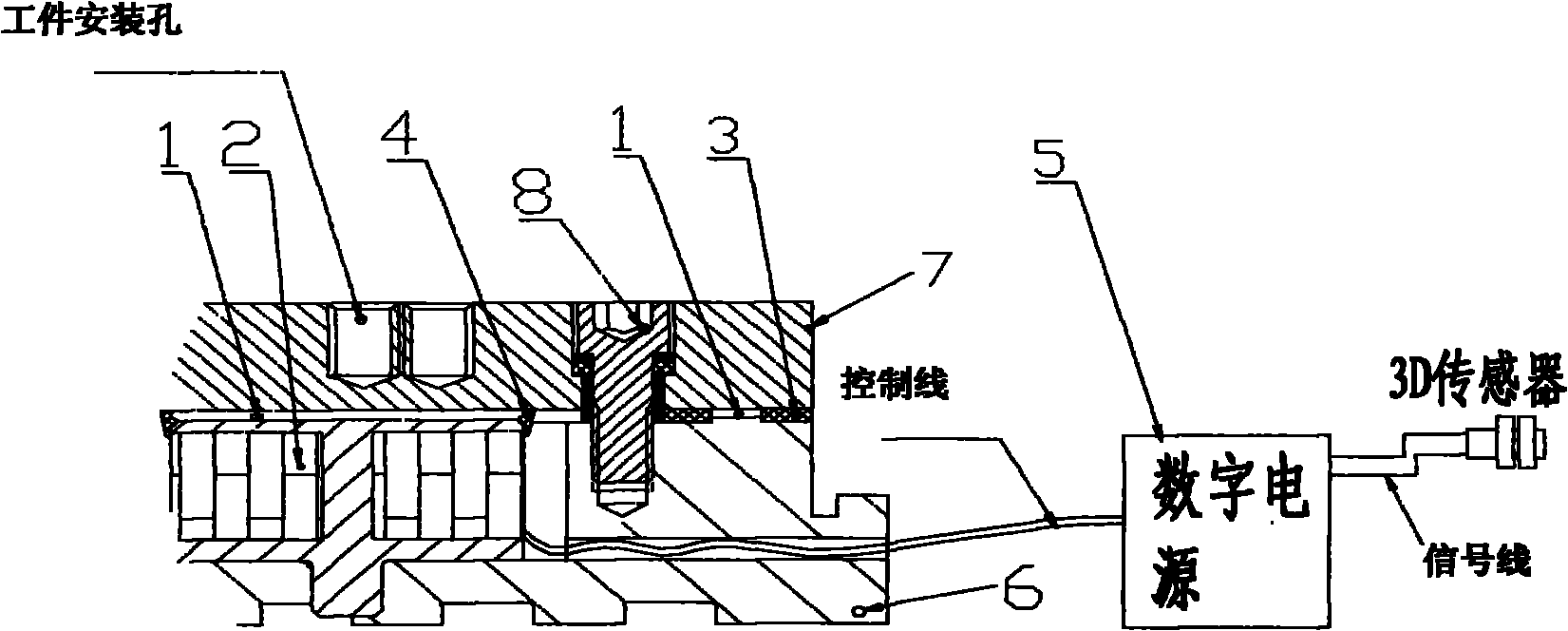

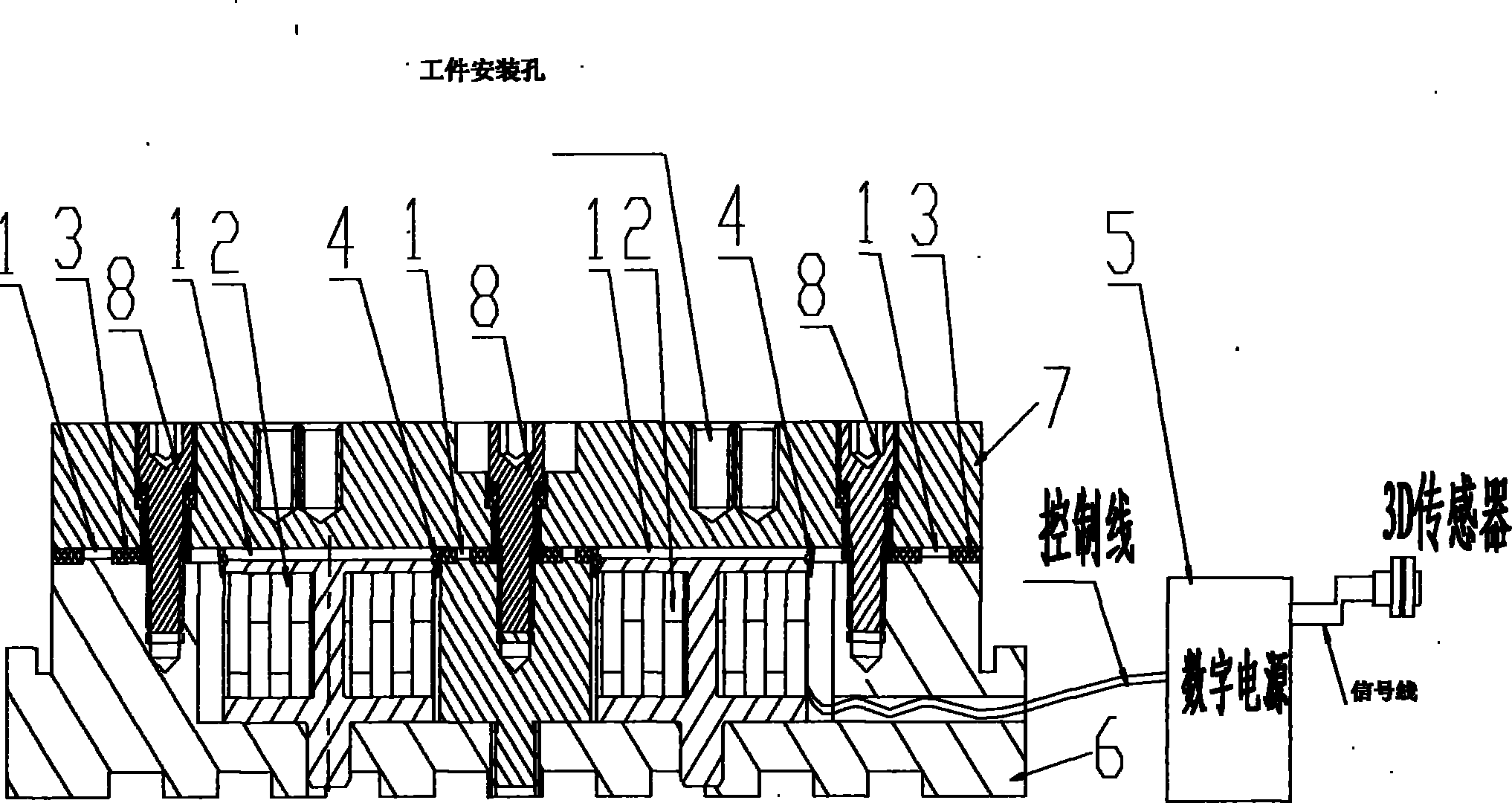

[0012] like figure 1 As shown, a machine tool intelligent shock-absorbing benchmark workbench includes intelligent materials-magnetorheological fluid (1), exciter (2), polymer solid damping gasket (3), liquid seal (4), digital power supply ( Including microcomputer) (5), workbench base (6), reference workbench (7), damping joint (8), 3D sensor (9). Among them, there are one or more exciters (2), which are determined according to the large and small range of the processed workpiece.

[0013] like figure 2 As shown, the reference table (7) on which the processed workpiece (or tool) is installed and the table base (6) are completely isolated by the magnetorheological fluid (1) and the polymer solid damping gasket (3), so that During the cutting process, the vibration energy of the machine tool itself and the cutting vibration energy force the vibration frequency to be grea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com