Guiding assembly and disassembly structure and mounting and dismounting methods of central spindle and protective barrel of probe

A technology for protecting cylinders and mandrels, which is applied in the field of oilfield instruments, and can solve problems such as mechanical parts and electronic parts being damaged, collided or squeezed, and installation difficulties, and achieve the effects of easy parts, convenient operation, and smooth assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

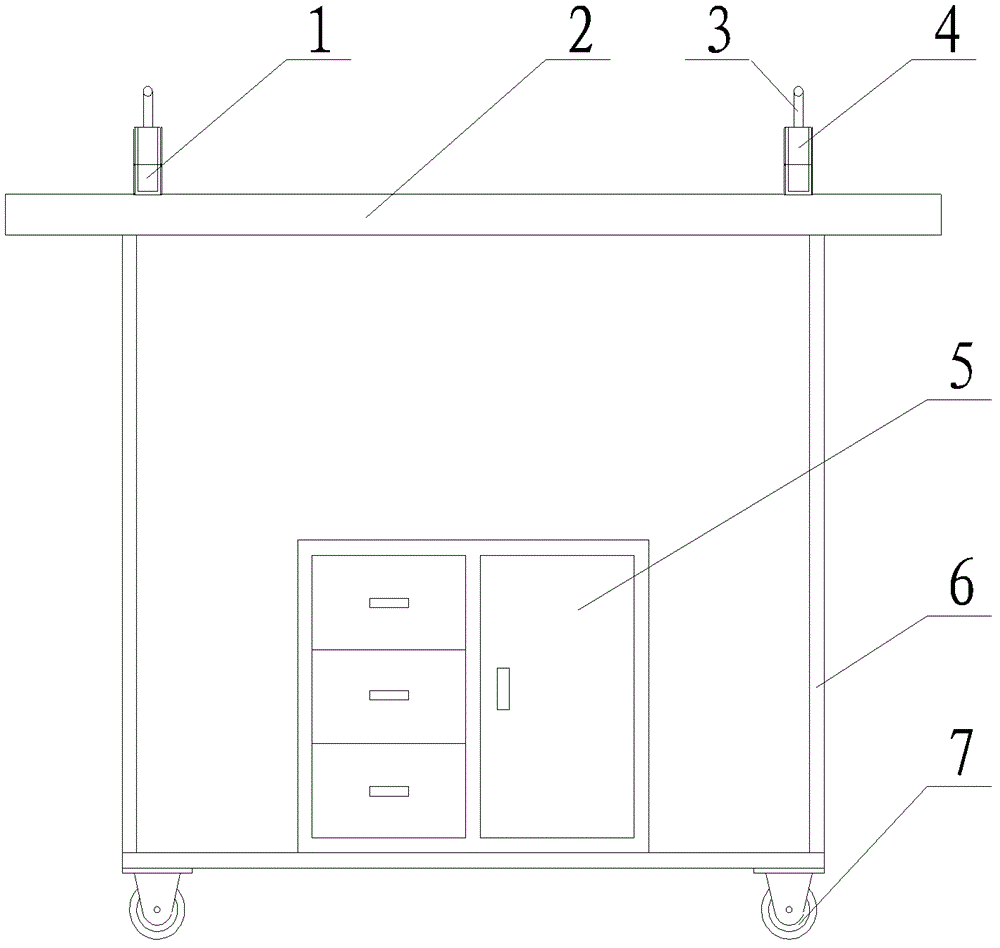

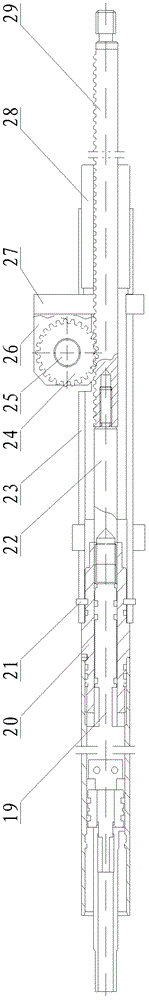

[0023] Figure 1 to Figure 3 The shown assembly and disassembly structure of the mandrel of the probe tube and the protective tube includes: a mandrel support mechanism for placing the mandrel, a clamping mechanism for the protective tube for fixing the protective tube, and an axial movement mechanism.

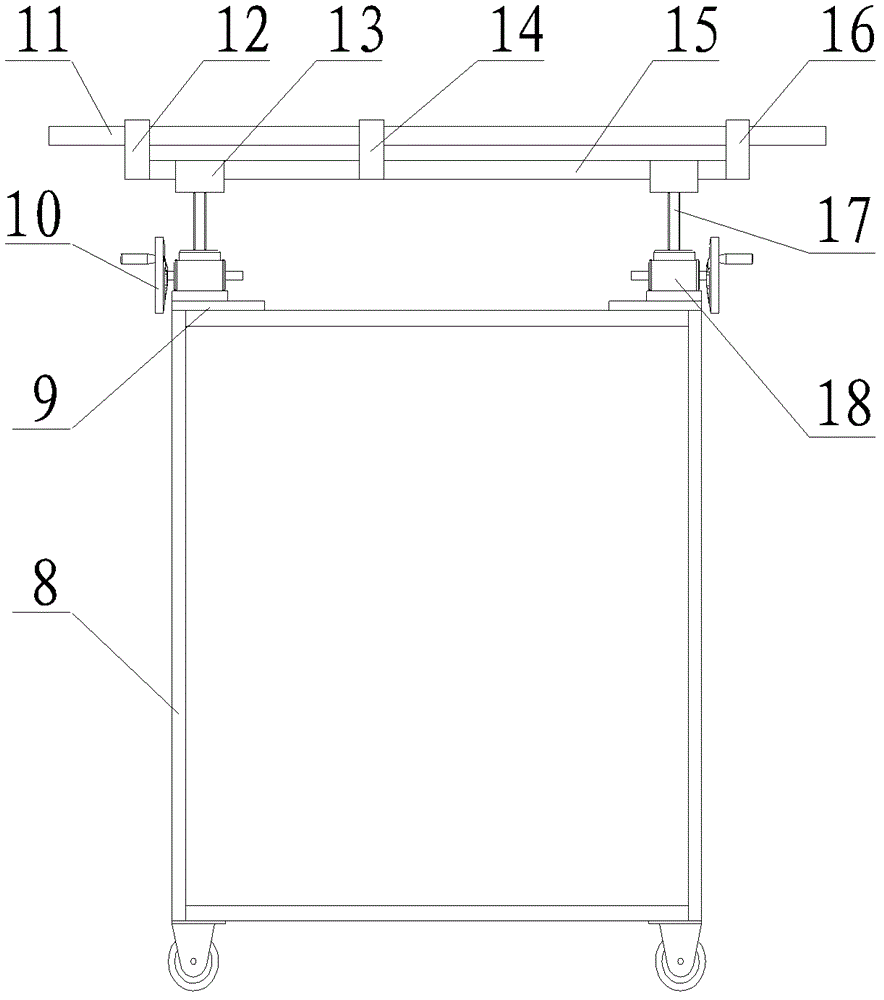

[0024] figure 1 The mandrel support mechanism shown includes: a mandrel support frame, a lifting mechanism 18 , a bottom plate 9 and a first bracket 8 . The mandrel supporting frame includes: a sliding pad 11, a front-end insertion block 12, two U-shaped supporting plates 13, an intermediate bracket 14, connecting angle steel 15 and a rear-end bracket 16. The connecting angle steel 15 is elongated, and the front end insertion block 12, the middle support 14 and the rear end support 16 are fixed successively above it. The front end insert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com