Antiskid assembly tire for motor vehicle

A motor vehicle, anti-skid technology, applied in the direction of anti-skid devices, vehicle parts, tire parts, etc., can solve the problems of inconvenient operation, body jitter, and locking deviation from the center of the tire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

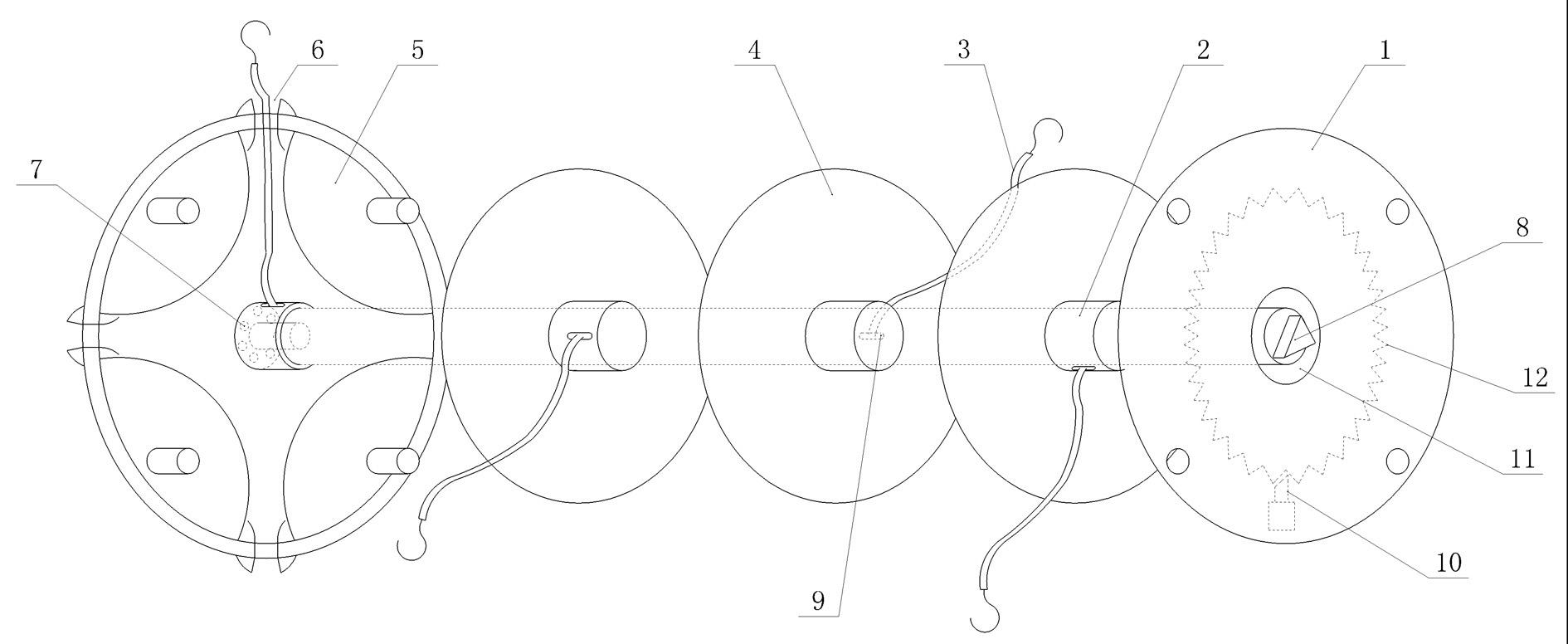

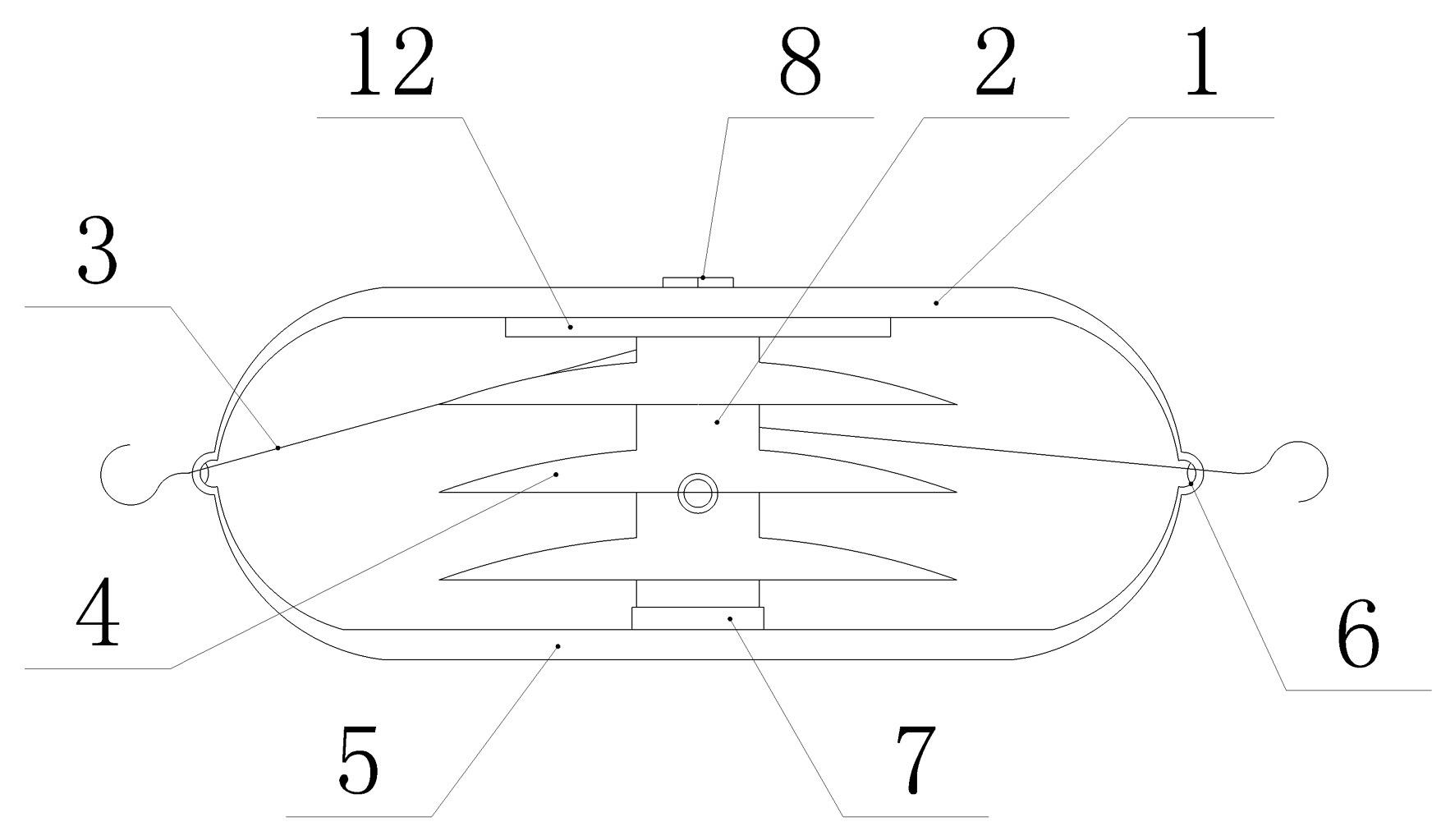

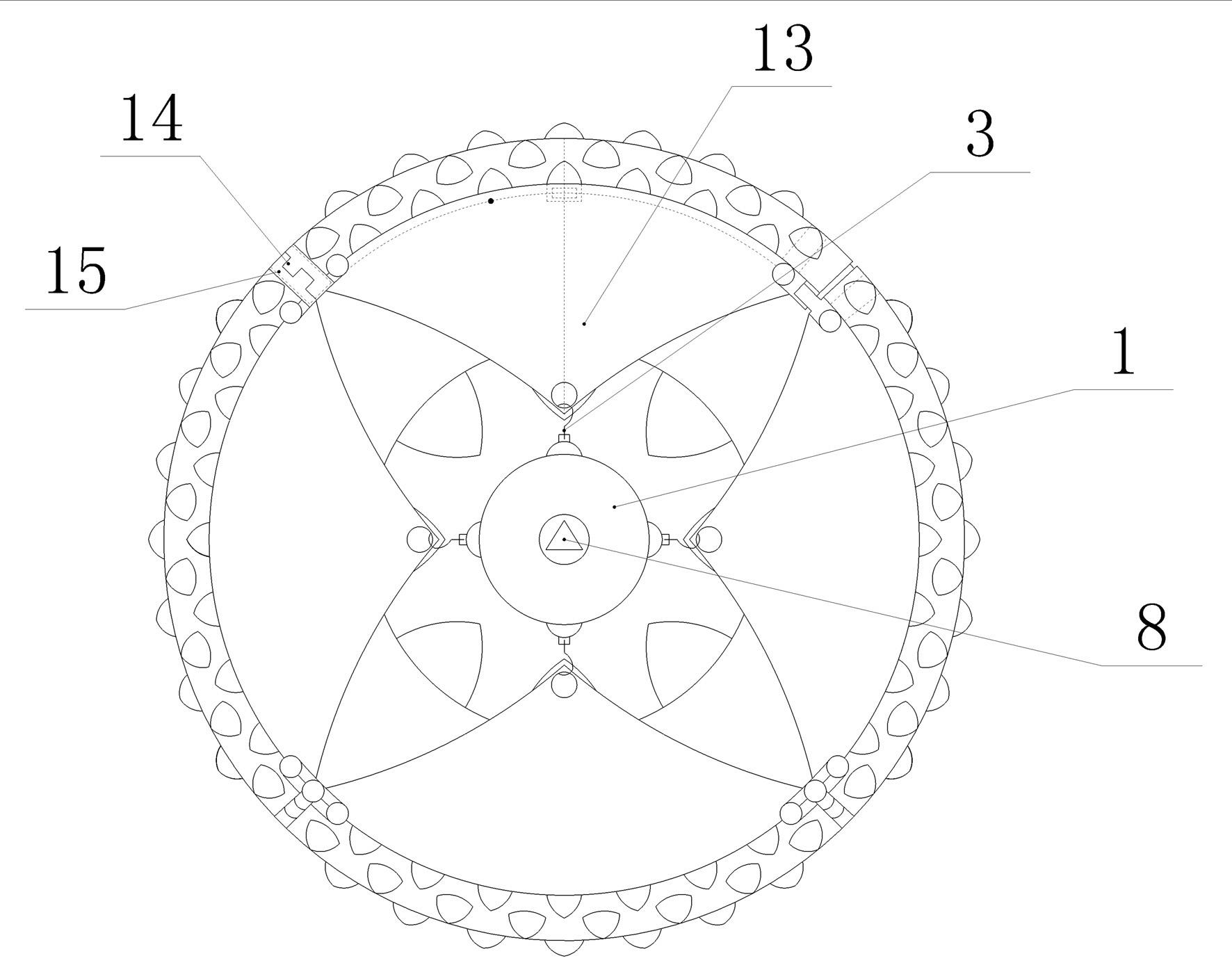

[0021] refer to Figure 1-Figure 4 , a motor vehicle anti-skid equipment tire, comprising a tread rubber interface 14, an outer bead rubber 13 and a synchronous locking device, the synchronous locking device includes a transmission shaft 8, a cover plate 1, and a back plate 5 with a bearing 7 in the center , and one end is provided with the stay rope 3 of hook, and the edge of back plate 5 is provided with the outlet hole 6 corresponding with every petal outside bead rubber 13, and cover plate 1 is fixedly connected with back plate 5, and one end of drive shaft 8 is connected with bearing 7 assembly, the other end is the adjustment end exposed from the central through hole 11 of the cover plate 1, the adjustment end is fixedly connected with the gear 12, and the gear 12 is matched with the limit pin 10 arranged on the cover plate 1;

[0022] The transmission shaft 8 is provided with a slot 9 corresponding to the outer bead rubber 13 of each petal. The fixed end of the stay rop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com