Preparation method of solvent-based two-component wind turbine blade protective primer

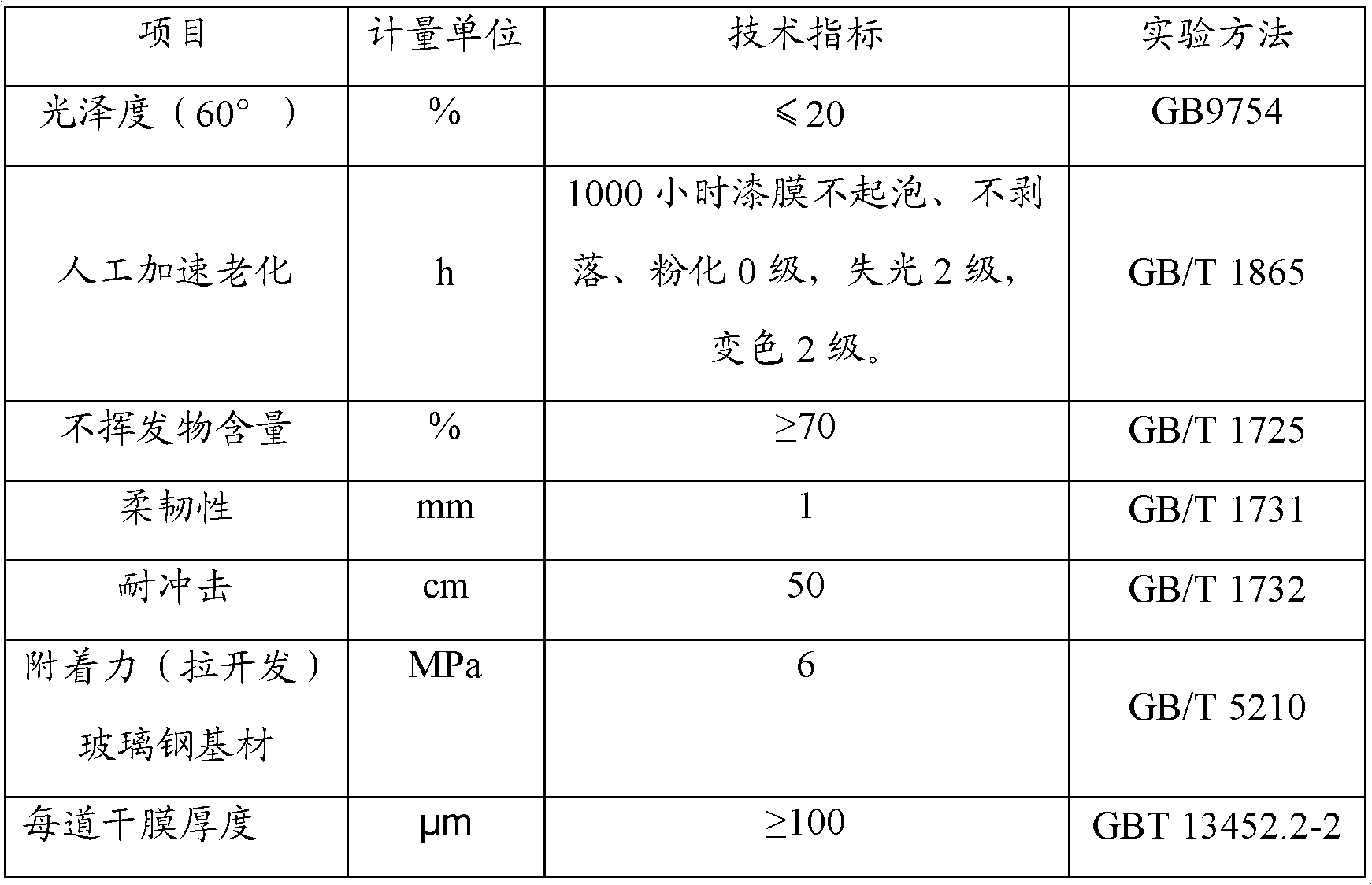

A two-component technology for wind turbine blades, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as slow drying speed, inability to carry out thick film coating, and limited application range, and achieve fast drying speed and good protection effect, the effect of excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] Preparation of component A: Add 0.1% to 0.5% of defoamer, 0.1% to 0.5% of defoamer, 0.1% to 0.5% of Adhesion promoter, 0.1% to 0.5% coupling agent, 0.5% to 3% wetting and dispersing agent, 0.5% to 2% thixotropic agent and 3% to 40% solvent; after stirring for 5 to 10 minutes, Add 15% to 30% of titanium dioxide and stir at high speed for 40 to 50 minutes, then add 4% to 7% of matting agent and stir evenly;

[0033] Wherein, the content of modified hydroxy acrylic resin is preferably 30% to 40%;

[0034] The content of the defoamer is preferably 0.2% to 0.4%;

[0035] The content of defoaming agent is preferably 0.2% to 0.4%;

[0036] The content of the adhesion promoter is preferably 0.3% to 0.5%;

[0037] The content of the coupling agent is preferably 0.3% to 0.5%

[0038] The content of matting agent is preferably 4% to 7%;

[0039] The content of the wetting and dispersing agent is preferably 0.5% to 2%, more preferably 1% to 2%;

[0040] The preferred content ...

Embodiment 1

[0056] The first step: preparing component A and component B;

[0057] Preparation of component A: 1 gram of polyamine block copolymer solution-based wetting and dispersing agent, 0.4 gram of carboxyl-containing adhesion promoter, 0.3 gram of silane coupling agent, 0.2 gram of acrylate polymer Foaming agent, 0.3 gram of acrylic acid copolymer defoamer, 1 gram of composite thixotropic agent (wherein, 0.4 gram of meteorological silica, 0.6 gram of modified urea thixotropic agent) are added to 30 grams of modified hydroxyacrylic resin, Then add 30 grams of solvent (including 15 grams of butyl acetate and 15 grams of propylene glycol methyl ether acetate) and stir for 5 to 10 minutes, then add 30 grams of titanium dioxide and stir at high speed for 40 to 50 minutes, and finally add 6.8 grams of meteorological silica matting powder and stir 15min.

[0058]Preparation of component B: Dissolve 65 grams of HDI trimer in 35 grams of butyl acetate and stir well to mix evenly.

[0059]...

Embodiment 2

[0061] The first step: preparing component A and component B;

[0062] Preparation of component A: 1 gram of polyamine block copolymer solution-based wetting and dispersing agent, 0.4 gram of carboxyl-containing adhesion promoter, 0.4 gram of silane coupling agent, 0.3 gram of acrylate polymer Foaming agent, 0.2 gram of acrylic acid copolymer defoamer, 0.8 gram of composite thixotropic agent (wherein meteorological silica 0.4 gram, modified urea thixotropic agent 0.4 gram) joins the inside of 46 gram of modified hydroxyacrylic resins, and then Add 19 grams of solvent (including 14 grams of butyl acetate and 5 grams of propylene glycol methyl ether acetate) and stir for 5 to 10 minutes, then add 26 grams of titanium dioxide and stir at high speed for 40 to 50 minutes, and finally add 5.9 grams of meteorological silica matting powder and stir for 15 minutes That's it.

[0063] Preparation of component B: Dissolve 74 grams of HDI trimer in 26 grams of butyl acetate and stir well...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com