High alloy tube piercing plug material and manufacturing method and surface processing method thereof

A technology for perforating plugs and perforating tubes is applied in the field of alloy materials, which can solve the problems of scrapped tube blank materials, difficult content control and high production costs, and achieve the effects of improving performance, good perforation effect and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

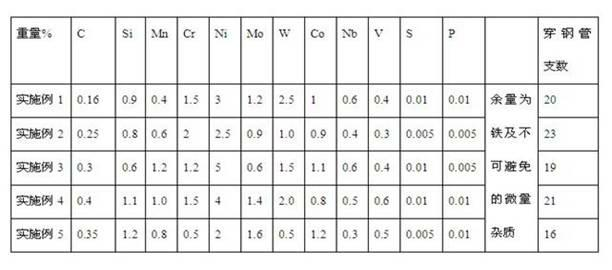

Embodiment 1

[0026] Example 1: high-alloy pipe piercing plug material, the composition weight ratio of the material is: C: 0.16%, Si: 0.9%, Mn: 0.4%, Cr: 1.5%, Ni: 3%, Mo: 1.2%, W : 2.5%, Co: 1%, Nb: 0.6%, V: 0.4%, S 0.01%, P 0.01%, and the balance is iron and unavoidable trace impurities.

[0027] During manufacturing, the above elements are put into the intermediate frequency furnace to melt according to the proportion, the heat preservation temperature is 1600-1750 ℃, the temperature of molten steel is 1460-1550 ℃, and then the blank of the plug is cast by ordinary sand casting, and it is completely annealed after cooling, and the annealing temperature is 870-890°C, and finally processed by machine tools.

[0028] The method for carrying out surface treatment to the above-mentioned high-alloy pipe perforation plug material comprises the following steps:

[0029] use C 3 h 6 Cleaning high-alloy pipe perforation plug material;

[0030] Put the high-alloy pipe perforated plug ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com