Water permeable stone paving block

A technology of stone grains and blocks, which is applied in the field of permeable pavement blocks on pavement, can solve the problems of compression resistance, low flexural performance, and easy breakage of products, and achieve excellent water permeability, improved flexural performance, and not easy The effect of dust clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

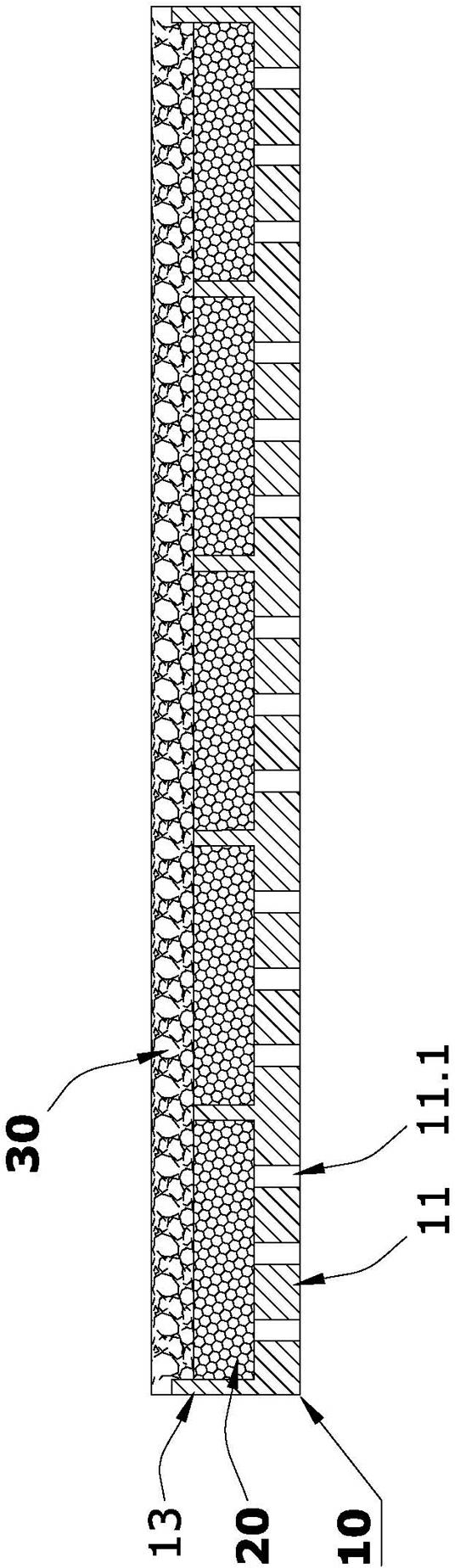

[0030] Example one (The surface layer is colored pebbles, and the permeable holes of the permeable board are cylindrical holes).

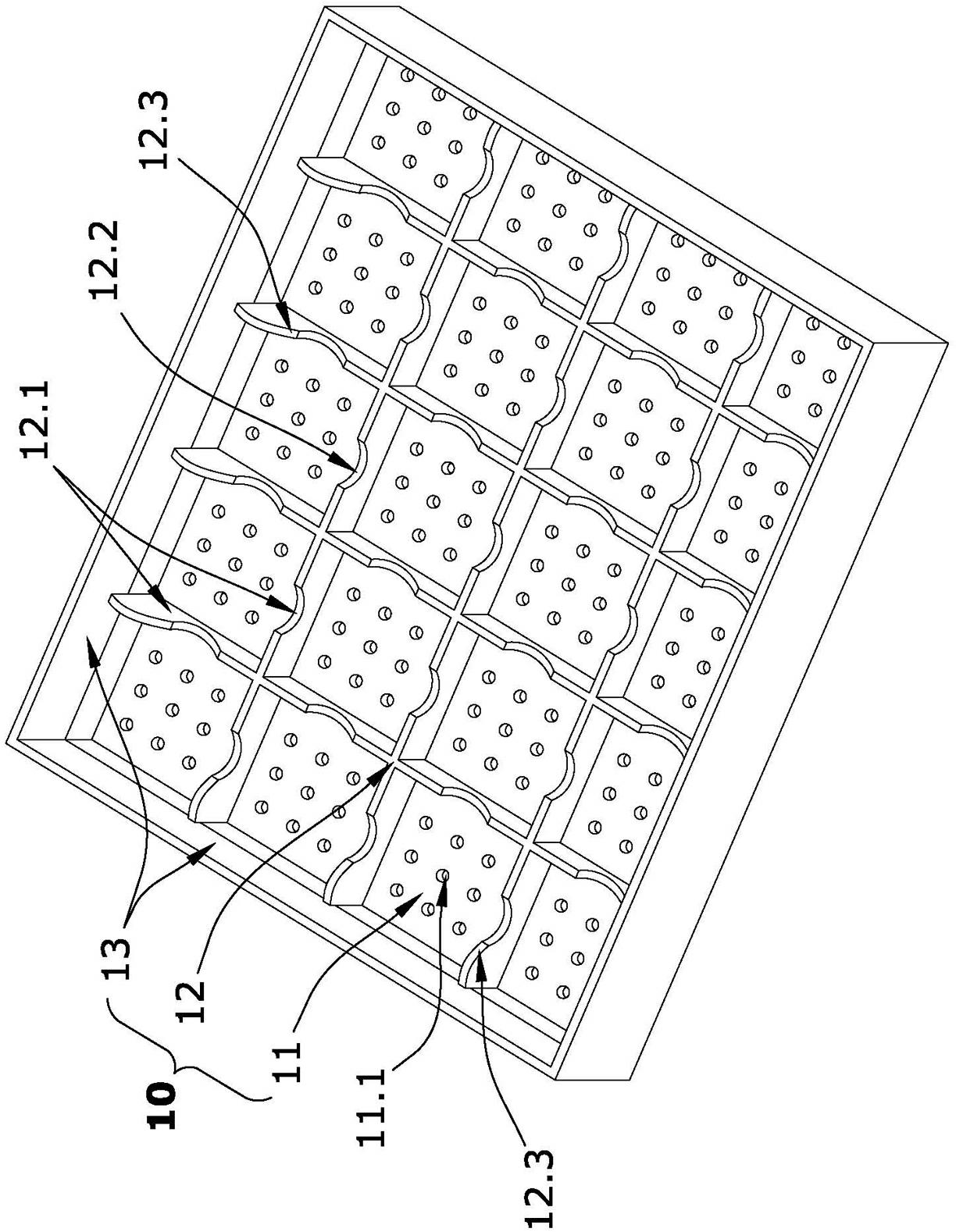

[0031] Such as figure 2 The shown one kind of permeable stone paving plot is mainly composed of permeable grid frame board 10, filled on the permeable grid frame board 10 on the permeable board 11, and the grid frame 12 is bonded to each other A permeable stone material cushion layer 20 composed of stone material and a color stone material surface layer 30 bonded on the permeable stone material cushion layer 20 and composed of mutually bonded colored pebbles as stone particles . The permeable grid frame board 10 is injection molded from modified polyethylene.

[0032] Such as figure 2、 image 3 As shown, a number of water-permeable holes 11.1 are provided on the bottom water-permeable plate 11 in the quadrilateral water-permeable grid frame plate 10, and the water-permeable holes 11.1 in this embodiment are cylindrical holes. The cells in the part o...

Embodiment 2

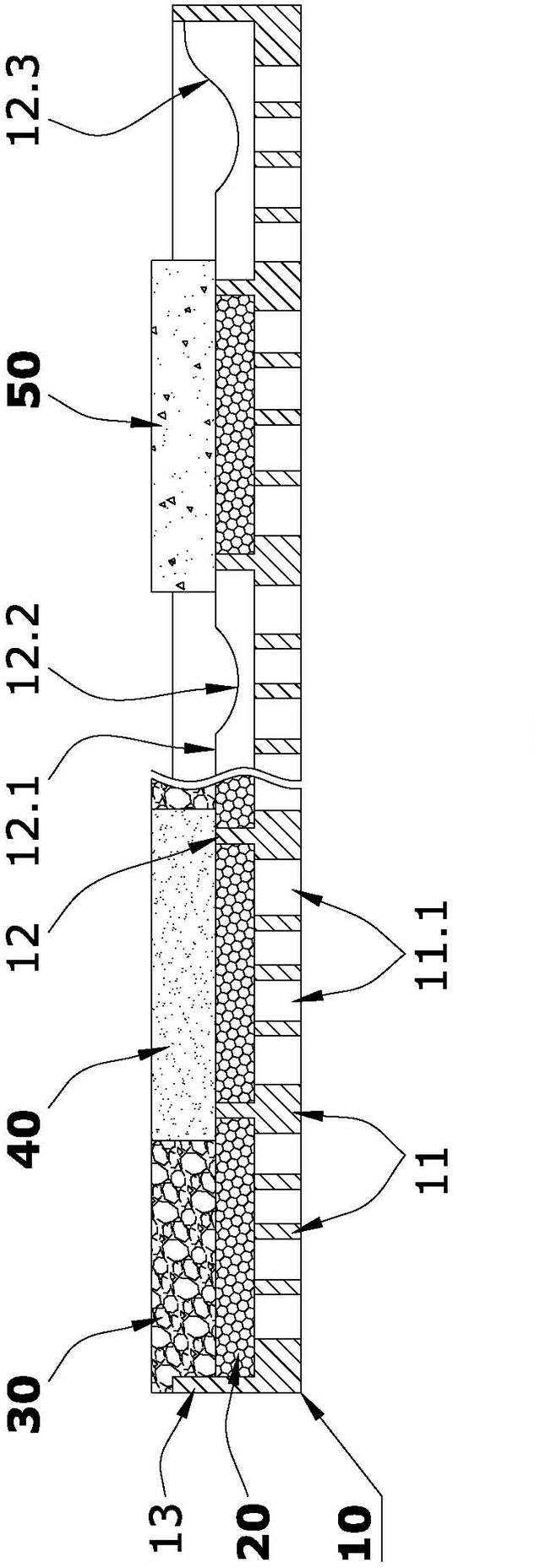

[0033] Example two (The surface layer is mixed and bonded with colored pebbles and granite impervious paving, and the permeable holes of the permeable board are prismatic holes).

[0034] Such as figure 1 with Figure 4 As shown, the permeable grid frame plate 10 used in this embodiment has permeable holes 11.1 in the permeable plate 11 part of a quadrangular prism hole; the lattice frame 12 above the permeable plate 11 is connected to the frame plate 13. 12. Other grids in the middle of 12.1.

[0035] The size of the permeable grid frame board 10 of this embodiment is 40×50×4.6 cm 3 , The thickness of the permeable plate 11 is 1.1cm, the aperture of the permeable hole 11.1 is 1.5×1.5cm; the height and thickness of the grid piece 12.1 of cell 12 are 2.0cm and 0.32cm, respectively, the grid frame 12 is in line with the permeable grid plate frame 10. The upper edge of the grid 12.1 connected with the surrounding frame plates 13 is wavy 12.3, that is, the height of the grid 12.1 in ...

Embodiment 3

[0036] Example three (The surface layer of oblate colored pebbles, the permeable holes of the permeable plate are prismatic holes and cylindrical holes).

[0037] Such as Figure 5 As shown, the water-permeable holes 11.1 on the water-permeable plate 11 at the bottom of the water-permeable grid frame plate 10 of this embodiment are a mixture of cylindrical and prismatic holes. The other structures and implementations are the same as those in the second embodiment; the colored stone material surface layer 30 adheres to each other The resultant stone grains are oblate colored pebbles with a plane radial diameter of 2.0 to 3.5 cm and a thickness of 1.0 to 1.5 cm; the surface layer of oblate colored pebbles is 1.0 cm higher than the upper edge of the frame plate 13 during production. In this embodiment, the permeable grid frame board 10 is injection molded from modified polypropylene (PP). The pressure resistance index of the permeable pavement paved with the permeable stone pavemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com